165

18.Withtheassistanceofatleastasecondperson,iptheBase

Assembly until the Walking Belt rests on the ground.

Asthemachineisipped,theLiftingShockwillextendand

pivot the Base Frame and Incline Frame Weldments. Be sure

to be clear of any pinch opportunities and not to grasp the

Base Assembly from these shifting parts. Do not grasp the

Walking Belt since it can abruptly move.

Note: the following image shows the Base Assembly on the side, not

fullyippedandrestingatontheWalkingBelt.

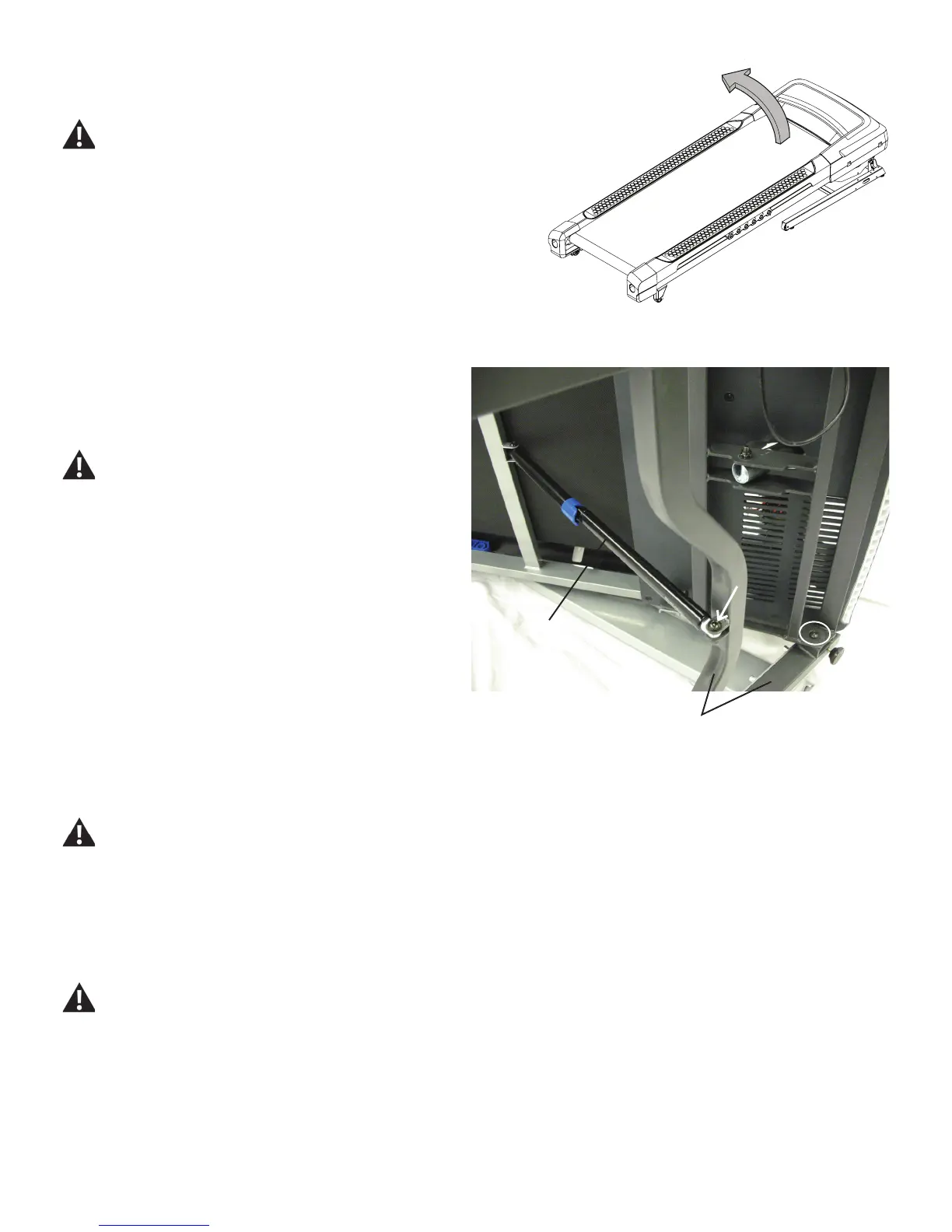

19. Using a 13mm wrench and a 6mm hex wrench, remove the indi-

cated hardware (with arrow) from the Lift Shock and lower the Base

Frame Weldment.

Be aware that when the Lift Shock is released from the Base

Frame Weldment, the Weldment may abruptly move and pivot

downward. Be sure to keep clear of any potential pinch

opportunities from this motion.

20. Using a 13mm wrench and a 6mm hex wrench, remove the 2

screws (one shown here with oval) from the Deck Frame and the

Base Frame Weldment.

21. Using a 13mm wrench and a 6mm hex wrench, attach the new

Base Frame Weldment to the Deck Frame.

22. Using a 13mm wrench and a 6mm hex wrench, re-attach the Lift

Shock to the Base Frame Weldment.

Be sure to keep clear of any potential pinch opportunities

when pivoting the Base Frame Weldment.

23.Withtheassistanceofatleastasecondperson,iptheBase

Assembly to the Upright position. Be aware that the Lifting Shock will

begin to compress when placed back to an upright position, lowering

the Base Assembly.

Be sure the area is clear around the Base Assembly before

ippingit.DonotgrasptheWalkingBeltsinceitcanabruptly

move.

Lift Shock

BaseFrameWeldment

Loading...

Loading...