NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 42 / 42

Monthly Cleaning And Hygiene (or every 5000 selections)

For all versions: Espresso - Fresh Brewer - Instant

Expected time 18 minutes

ONCE A MONTH, OR EVERY 5000 SELECTIONS, THE

FOLLOWING SCHEDULED MAINTENANCE OPERATIONS

MUST BE CARRIED OUT; AS USUAL IT IS ADVISABLE TO

CARRY OUT SUCH OPERATIONS AT THE WORKSHOP, AND

ON SITE SIMPLY REPLACE THE UNITS WITH THE ONES

WHICH WERE ALREADY SUBJECTED TO SCHEDULED

MAINTENANCE.

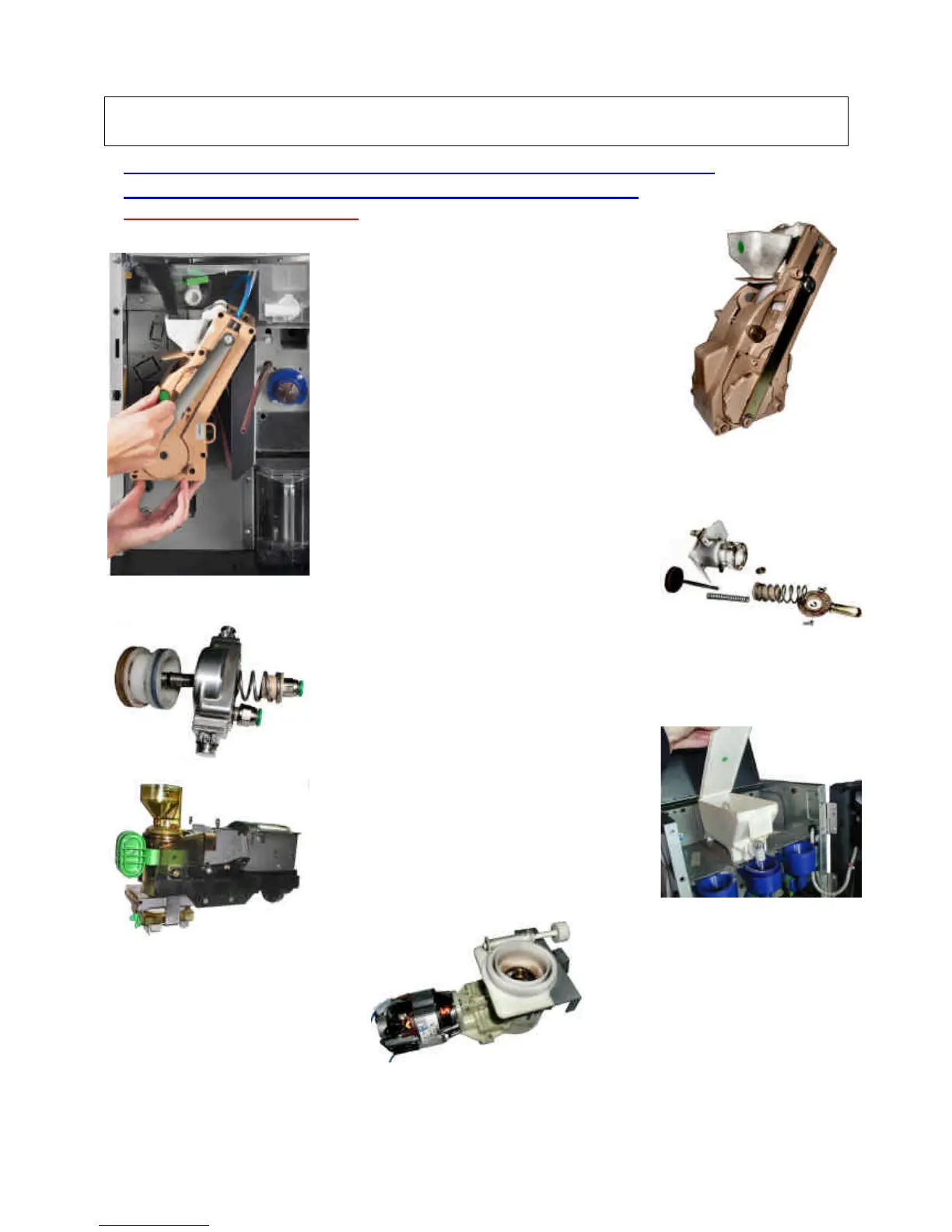

Remove the “Z3000’ unit from the vending machine

(FIG. 1 – FIG. 2); disassemble the unit completely,

remove the upper piston and the lower brewing

chamber (FIG. 3 – FIG. 4); carry out the

maintenance operations indicated in the specific

manual, and more specifically, clean or replace the

filters and lubricate the seals.

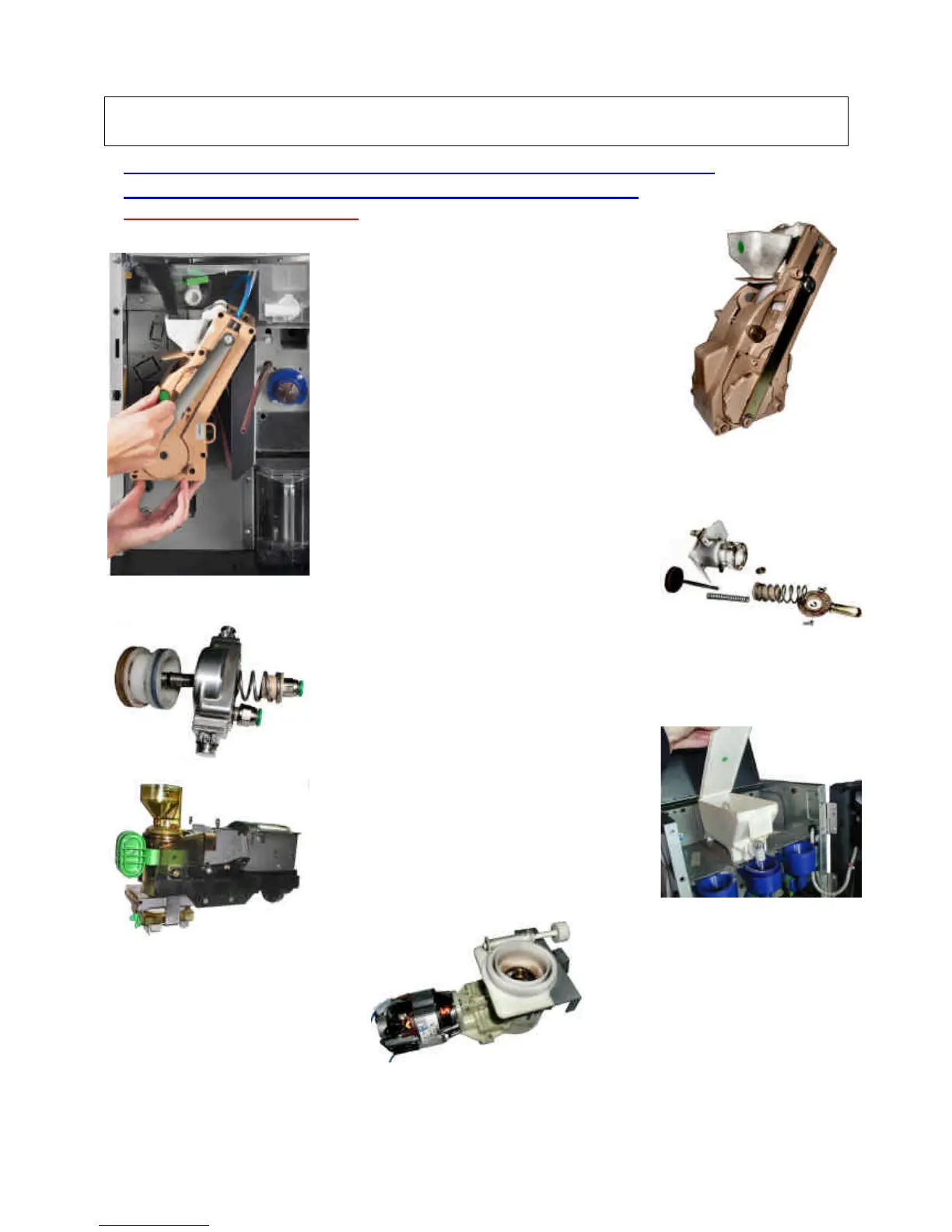

Remove the “SIGMA BREWER” unit from the

machine; clean thoroughly (see specific manual),

more specifically the brewing chamber and the lower

filter; check the efficiency of the mechanism and of

the position micro-switches.

If the filter is clogged for more than 50% must be

replaced (FIG. 5)

Remove the powder containers, empty and clean

them thoroughly in the inside, especially the ports

and the auger (FIG. 6)

Remove the grinder and doser assembly, empty any

coffee residue, check the state of the grinding

wheels, check the efficiency of the sensor that

detects the number of revolutions (FIG. 7)

Reset the correct distance between the grinding

wheels (see specific manual).

Reassemble all parts, taking care not to touch any

parts that come into contact with food.

Loading...

Loading...