Pipe connections 13

For the Installer

FIGHTER 310P

The enclosed expansion vessel (106) for tap water

shall be installed in the tap water circuit after the pres-

sure reduction valve.

Expansion vessel, tap water

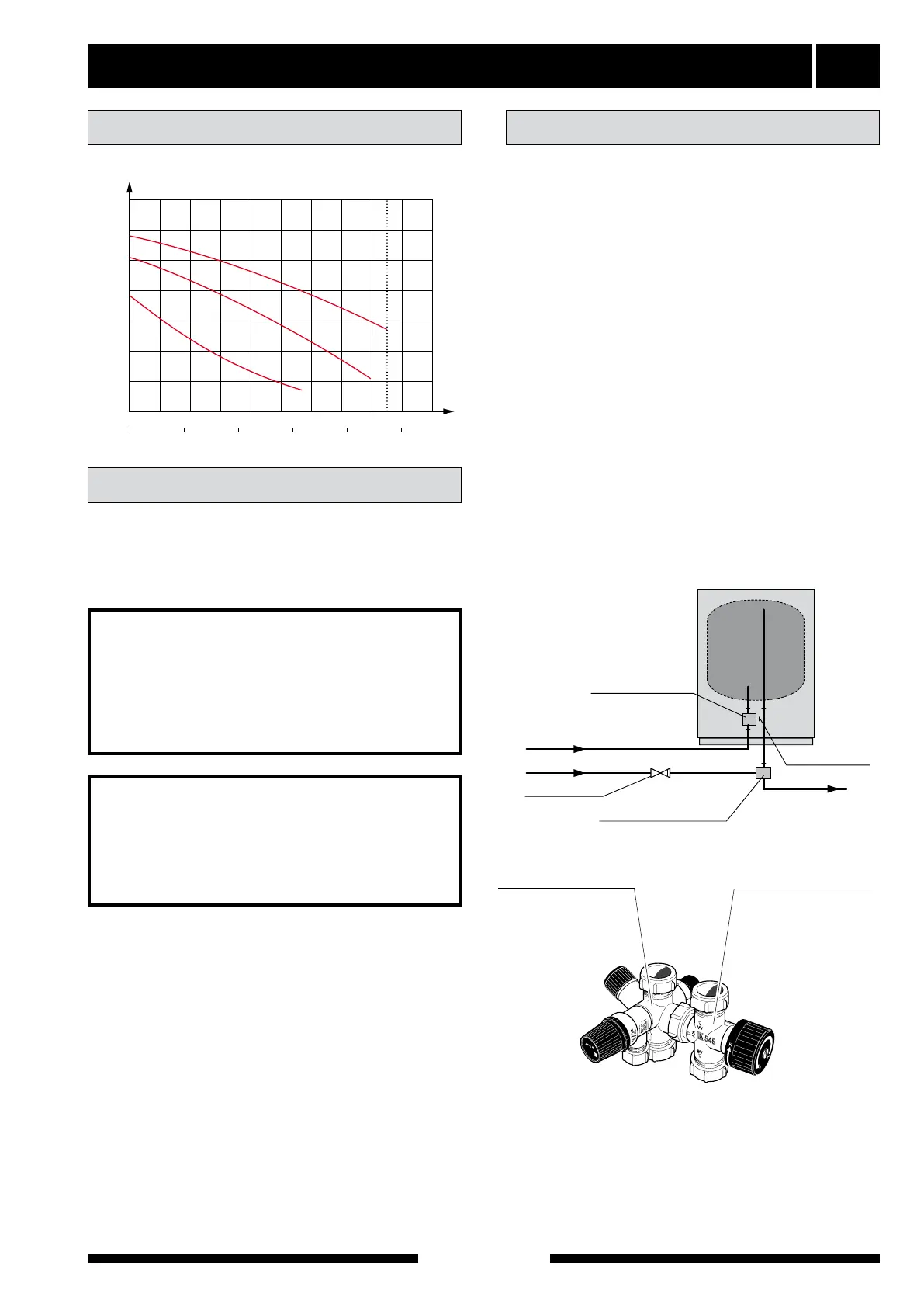

Pump and pressure drop diagrams

Pumpkapacitet

Flöde

Tillgängligt tryck, kPa

Internt tryckfall i panna

(inklusive armatur)

Tillgänglig pumpkapacitet

(pannans interntryckfall fråndraget)

3

2

1

0 500 1000

0

1500 2000

4

l/h

P

5

6

Interner Druckverlust in der Heizung

(einschließlich Armatur)

Zugängliche Pumpenkapazität

(interner Heizdruckverlust abgezogen)

3

2

1

kPa

kPa

60

50

40

30

20

10

0

mWs

l/s

0,50,40,30,20,10

Höchstmenge:1700 l/h

Höchstmenge:1700 l/h

3

2

1

0 500 1000

0

1500 2000

4

l/h

l/h

l/h

P

5

6

Internal pressure drop in boiler

(including fittings)

Available pump capacity

(less the internal pressure drop of the boiler)

3

2

1

wg

10

200

0

0

20

400

30

600

40

800

50

1000

60

1200

70

1400 1600 1800 2000

50

40

30

20

10

0

m

Flow

l/s

0,50,40,30,20,10

l/s

0,50,40,30,20,10

Max flow: 1700 l/h Max flow: 1700 l/h

Max flöde: 1700 l/h

l/s

0,50,40,30,20,10

Flow, l/h

Available pump capacity, kPa

10

200

0

0

20

400

30

600

40

800

50

1000

60

1200

70

1400 1600 1800 2000

Menge

Vorhandener Druck, kPa

10

200

0

0

20

400

30

600

40

800

50

1000

60

1200

70

1400 1600 1800 2000

Max flow

1700 l/h

Available pressure, kPA

Flow

Warning to the

installer!

This installation is subject to building

regulation approval, notify the Local

Authority of intention to install.

Warning to the

installer!

Use only manufacturer’s

recommended replacement parts.

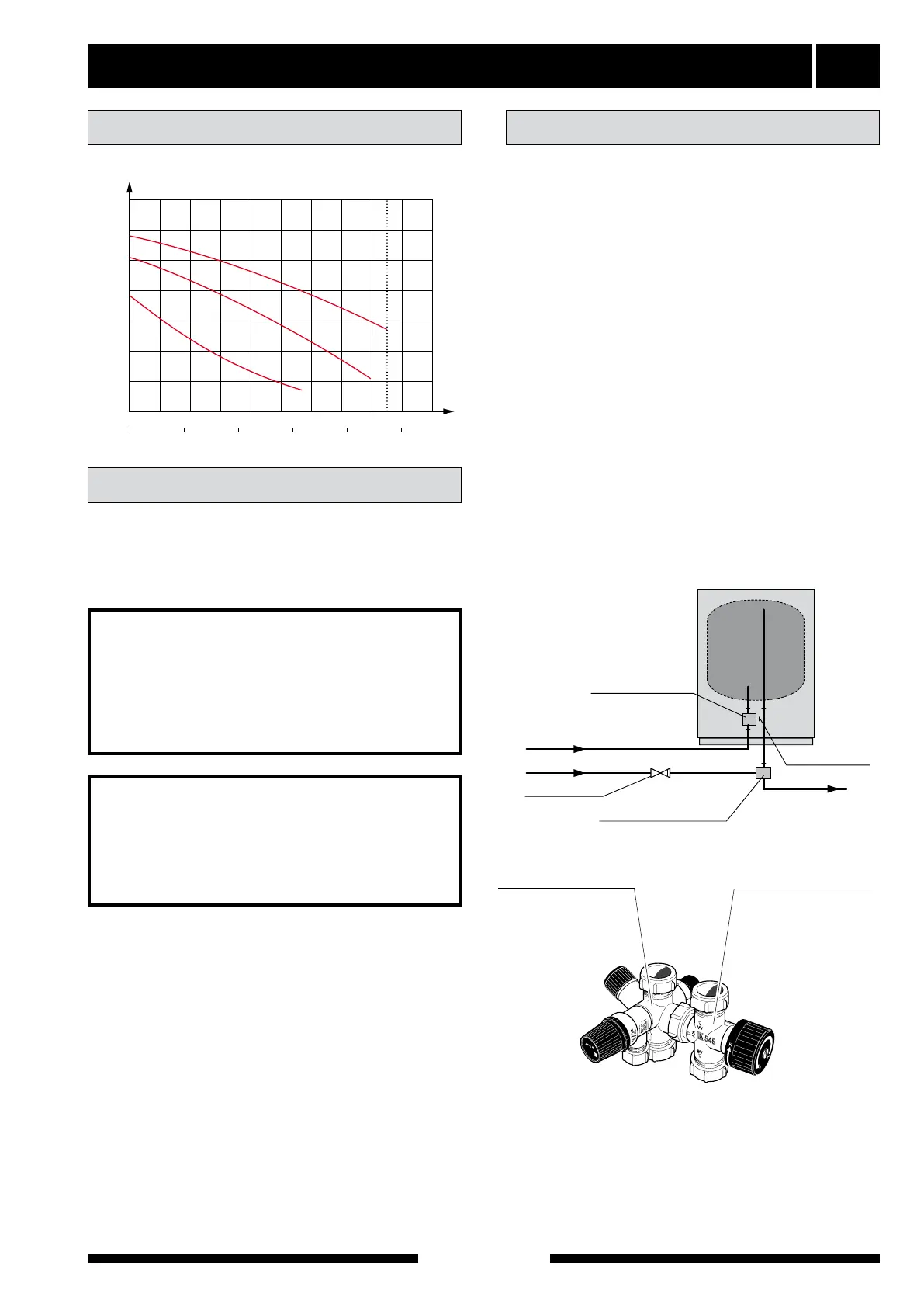

Tap water connection

Hot and cold water are connected to pos (74) (hot

water) and (73) (cold water).

The attendant expansion vessel (107) must be con-

nected to the hot water system.

The heat pump should be supplemented with an elec-

tric water heater if a bubble pool or other significant

consumer of hot water is installed.

If the heater is equipped with a valve connection Ø of

15 mm, this should be replaced with an equivalent

(split) Ø 22 mm coupling.

Appropriate heaters are COMPACT 100-300 for floor-

mounting and EMINENT 35-100 for wall-mounting.

1. Split the valve coupling.

2. Attach the valve coupling section to the heater’s

incoming cold water.

3. Attach the mixing valve section to the heater’s out-

going hot water.

4. Plug the split on the valve coupling section.

LK 550/506/513 LK 545/506/513

LK 545/508/518 MMA MMA/LK 518 SYR

LK 506

LK 501

SOLE

LK 545/508/514 LK 545/508/514

utan vakuumventil

LK 550/Cu-rör/506//513 LK 540/512

LEK

LEK

LEK

LEK

LEK

LEK

0,9

MPa

LEK

LEK

LEK

LEK

LK 560/514

ARMATUR

LEK

LEK

LEK

ARMATUR

LEK

ARMATUR

Valve coupling section

Mixing valve section

KV

VV

VV

INK KV-ANSL

PROPPNING

KV

VV-BEREDARE

MED "DELAT"

VENTILKOPPEL

BACKVENTIL

Kv

Vv från värmepump

Vv

Proppas

Backventil

KV

VV

VV

INK KV-ANSL

PROPPNING

KV

VV-BEREDARE

MED "DELAT"

VENTILKOPPEL

BACKVENTIL

Ventilkoppel-del

Blandningsventil-del

Kv

Vv från värmepump

Vv

Backventil

Blandningsventil

ENDAST FÖR

DANMARK

Valve coupling section

Plugged

Non-return valve

Hw from heat pump

Cw

Hw

Mixing valve section

Loading...

Loading...