32 – ENGLISH

8.3.2 Signals with the display

In case of anomalies, the display can visualise an error code both during the boom’s movement and when the manoeuvre stops.

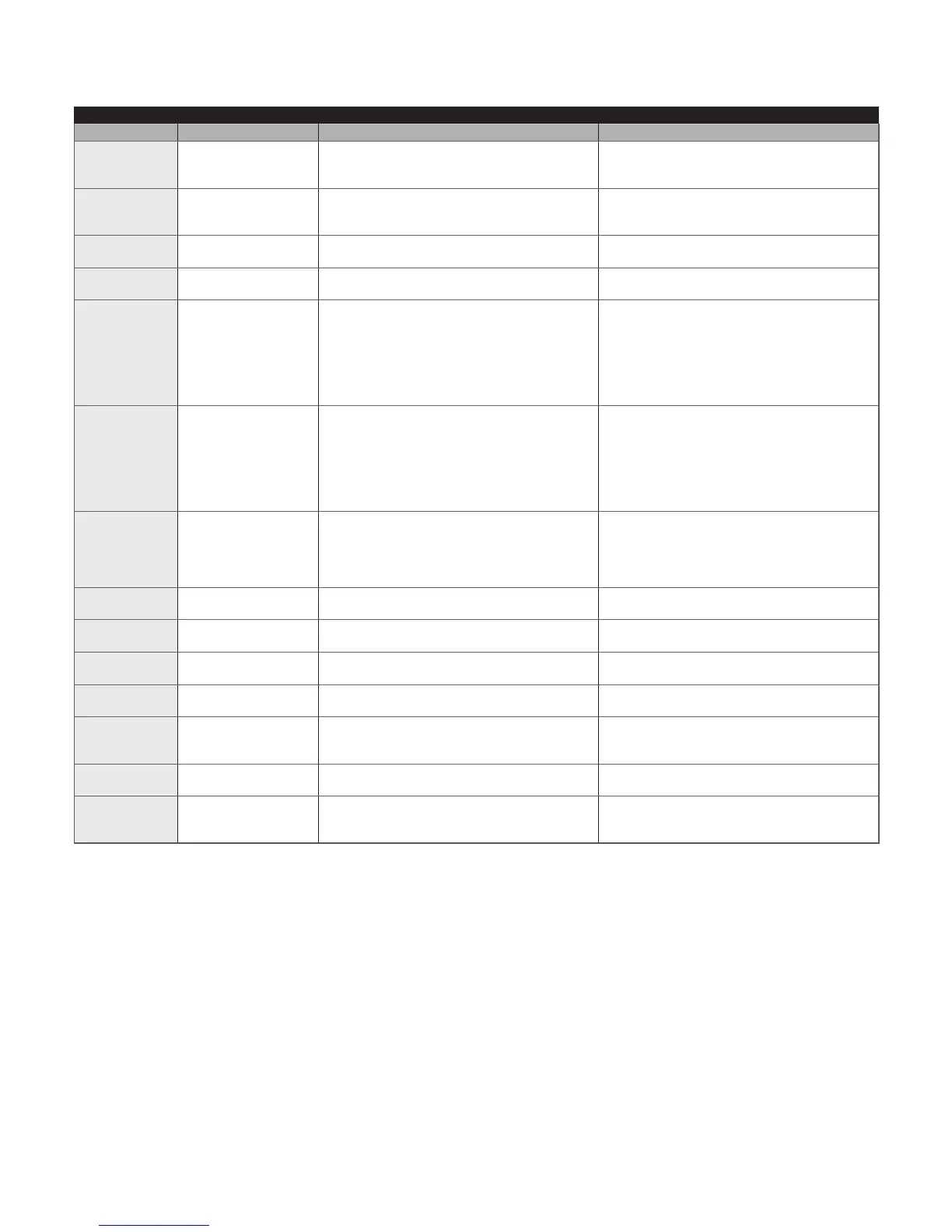

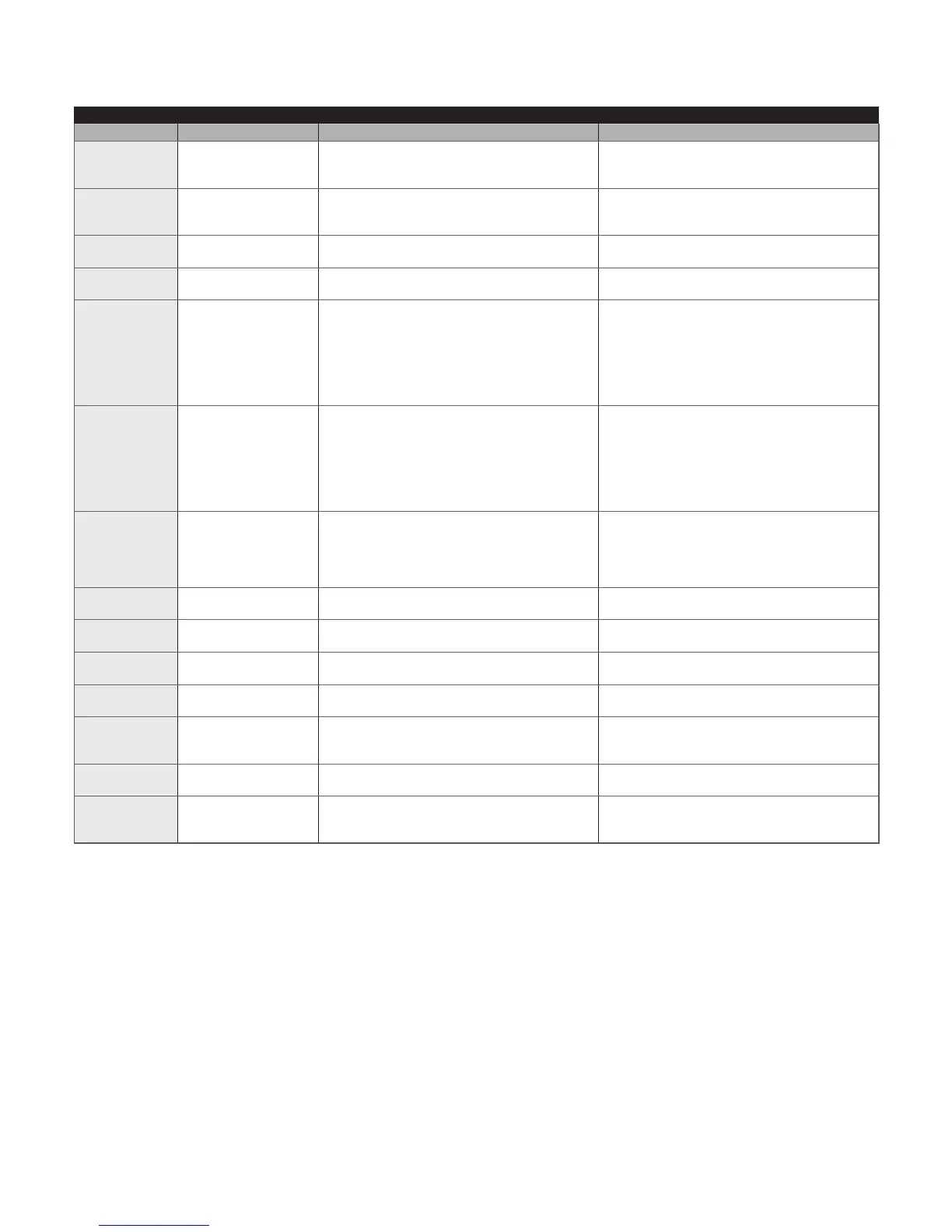

The following table shows the error codes that can be displayed.

Table 13

SIGNALS WITH THE DISPLAY

Error code Description Cause Meaning

E01

Memory of the

BlueBus or Stop

devices

There has been a change in the devices

connected to the Bluebus or Stop terminals,

or learning of the devices was never done

The connected devices must undergo the

learning procedure (refer to the “Device

learning” paragraph)

E02

Level memory or the

positions were never

learned

Learning of the positions was probably never

done

The boom’s opening and closing positions

must be learned (refer to the “Learning of the

mechanical stop positions” paragraph)

E03

Limit switches

inverted

E04

Encoder signal

Lack of communication between the sensor

present in the motor and the control unit

Check that the encoder cable is connected

and in good condition

E05

Master-Slave

communication

The Master and Slave control unit are not

communicating correctly between one

another

Check that the cable connecting the Master

and Slave control units is connected and that

the pole markings are observed

Check that the Slave control unit has been

selected and the Master learning phase has

been completed (refer to the “Gearmotor in

SLAVE mode” paragraph).

E06

Parameter memory

reading

Error in the internal parameters of the control

unit

Disconnect and reconnect the power supply.

If the error persists, delete the memory

entirely as described in the “Full deletion of

the control unit’s memory” paragraph and

redo the installation

If the condition persists, there’s a fault or the

electronic circuit board must be repeated

E07

Internal checks and

Class B tests

Error in the internal electric circuits

Disconnect all the power supply circuits; after

a few seconds, reconnect the power supply

circuits and try sending a command

If the condition persists, there’s a fault or the

electronic circuit board must be repeated

E08

Dip-switch

conguration

Probable tampering or failure of the barrier

selection dip-switch

Check that the dip-switch settings match the

factory settings

E09

Lock automation

The automation was stopped by a Lock

command

Send the “Unlock automation” command or

command the control unit with HP SbS

E10

Lack of safety input

(NC) or limit switch

There is no NC safety input or at least a limit

switch

Check the cable connected to the “Safety”

input and the operation of the limit switches

E11

Short-circuit at the

Bluebus output

One or more devices connected to the

Bluebus output have short-circuited

Try sending a command and wait 40 seconds

I02

Intervention of a

photocell

At the start of a manoeuvre or during the

movement, one or more photocells do not

give the enable signal

Check for any obstacles

I03

Intervention of the

motor force limiter

During the movement, the boom experienced

excessive friction

Verify the cause or increase the force level

I04

Intervention of the

devices connected to

the Stop input

At the start of the manoeuvre or during the

movement itself, the devices connected to the

STOP input intervened

Identify the cause

Loading...

Loading...