NORAM 65ET GRADER

3-11

Operation

3

Moldboard and Implement Operation

MOLDBOARD AND IMPLEMENT OPERATION

The moldboard and optional implements are hydraulically operated. Control levers are located on

each side of the front console. By actuating a switch on top of the front console, some control levers

operate multiple functions.

The transmission gear and engine speed should be set before engaging the ground with the

moldboard or implement. Never overload moldboard to the point that the rear wheels begin to slip.

This will alter the grade, increase wear on the tires and cause inefficient operation.

NOTICE: Using moldboard to back drag material should be avoided, if possible. Increased wear on the

moldboard guides and damage to the side shift cylinder rod may result.

Implement

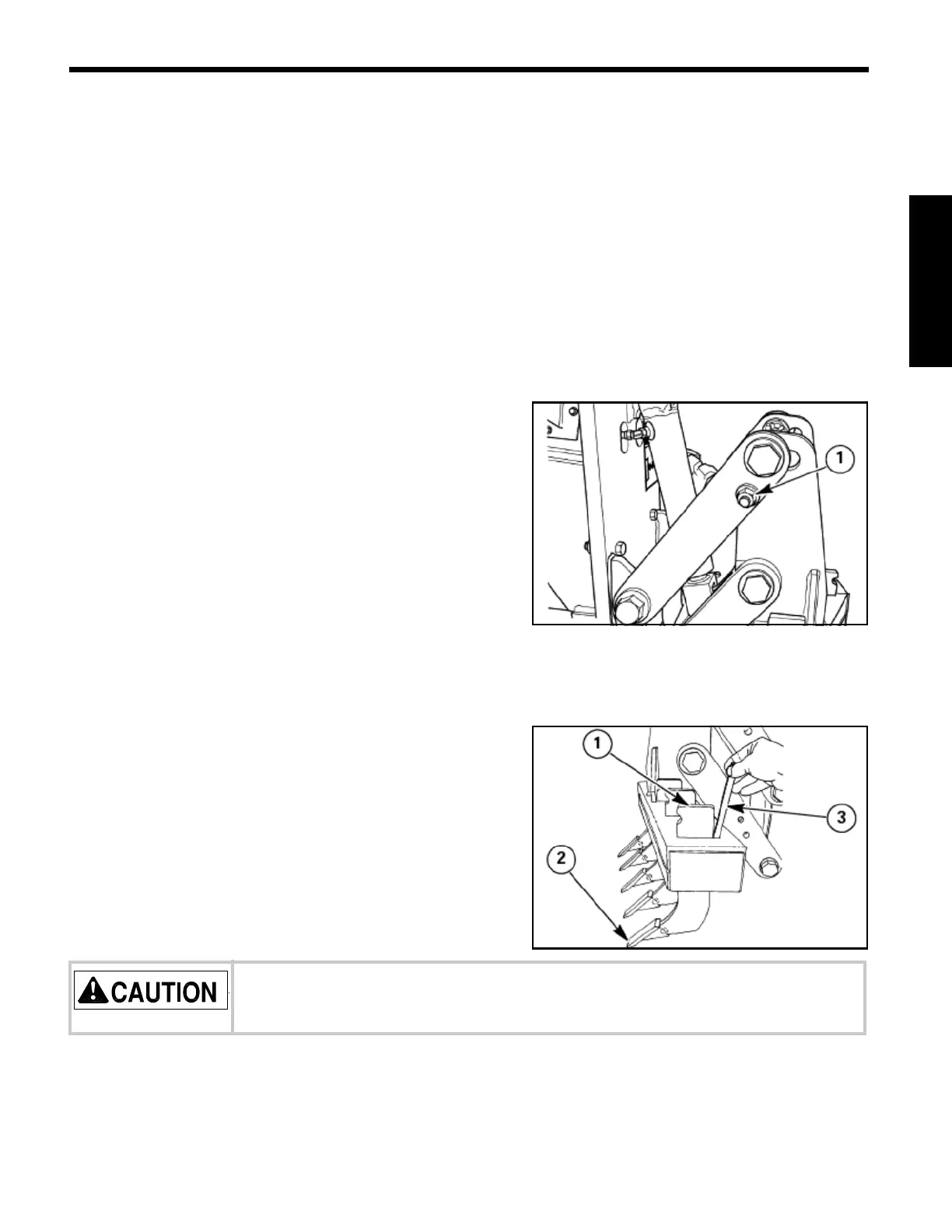

NOTICE: Front and rear-mounted implements, if installed,

have lock pins

(1) that must be removed to lower

implement.

The front of the motor grader may be equipped with an

optional dozer or scarifier. The rear of the motor grader

may be equipped with an optional ripper. They are

hydraulically operated. The scarifier and ripper can be

used to break out hard-packed material that the

moldboard can not penetrate. The dozer blade may be

used to level large piles which are not suitable to drive

the front wheels over.

NOTE: Front counterweights or front implements must be installed when rear ripper is

installed. Rear ripper and rear counterweights cannot be installed simultaneously.

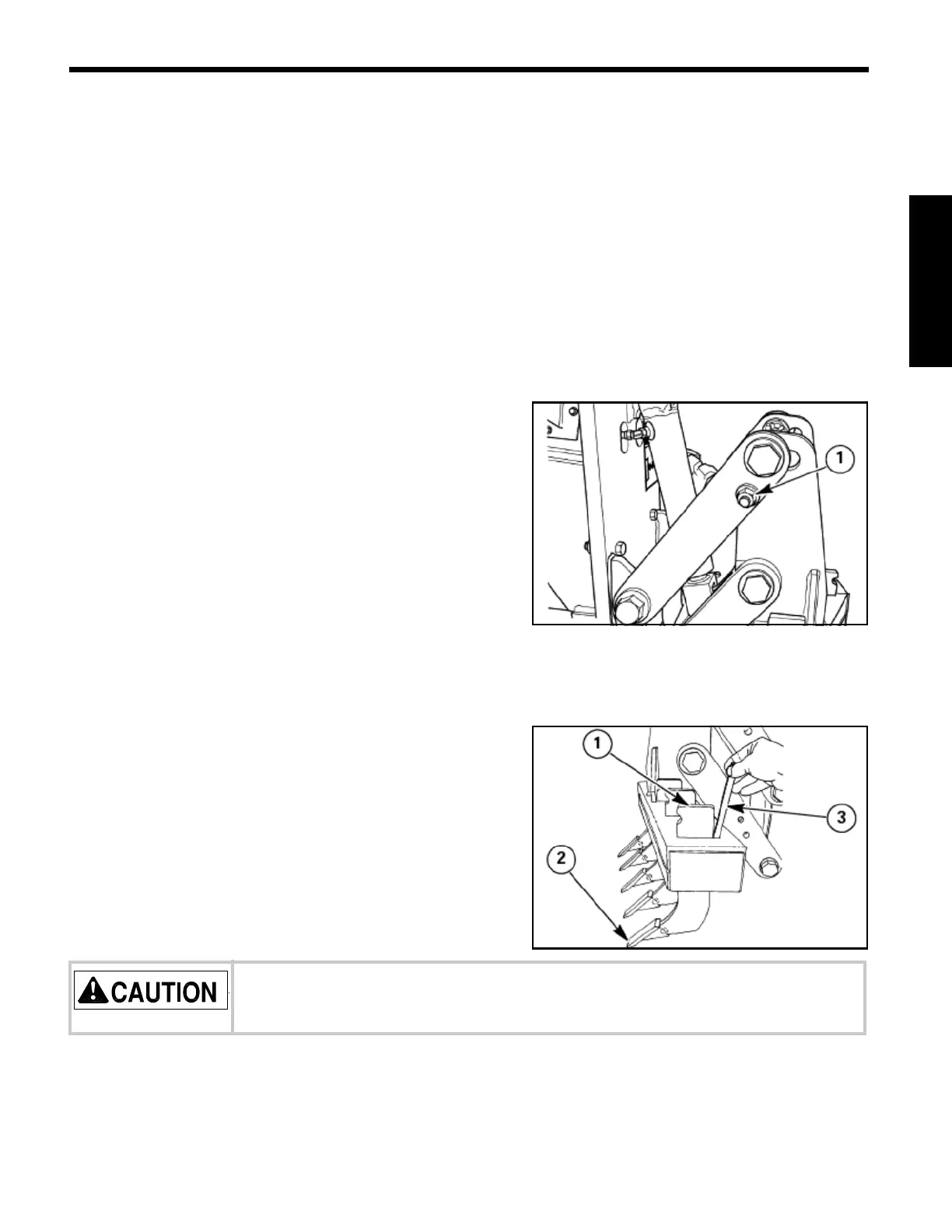

Scarifier and ripper shanks have two depth positions.

Each shank

(1) is equipped with a replaceable tooth, 2.

A lock pin

(3) holds the shank in place. To remove lock pin, tap on the bottom with a hammer until

free. Remove lock pin from the top of the tool bar and remove or reposition the shank.

To install, position shank in tool bar in the desired notch. Insert lock pin from top of tool bar until

fully seated.

Keep feet out from under toolbar, shanks may fall when lock pin is removed.

Loading...

Loading...