NORAM 65ET GRADER

4-8

Accessing Lubrication and Check Points

1

4

Lubrication and Maintenance - Grader Components

Lubrication/Fluid Level Check

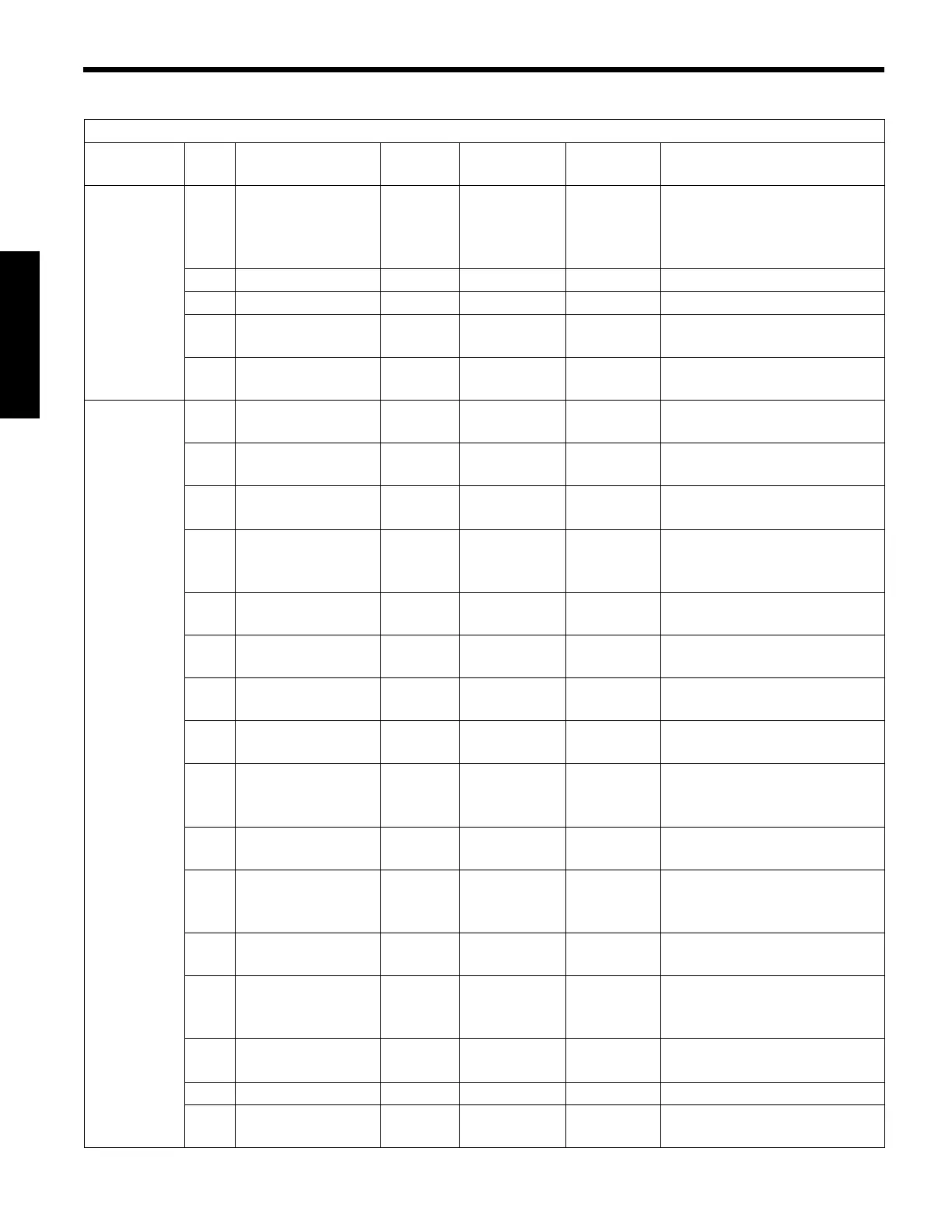

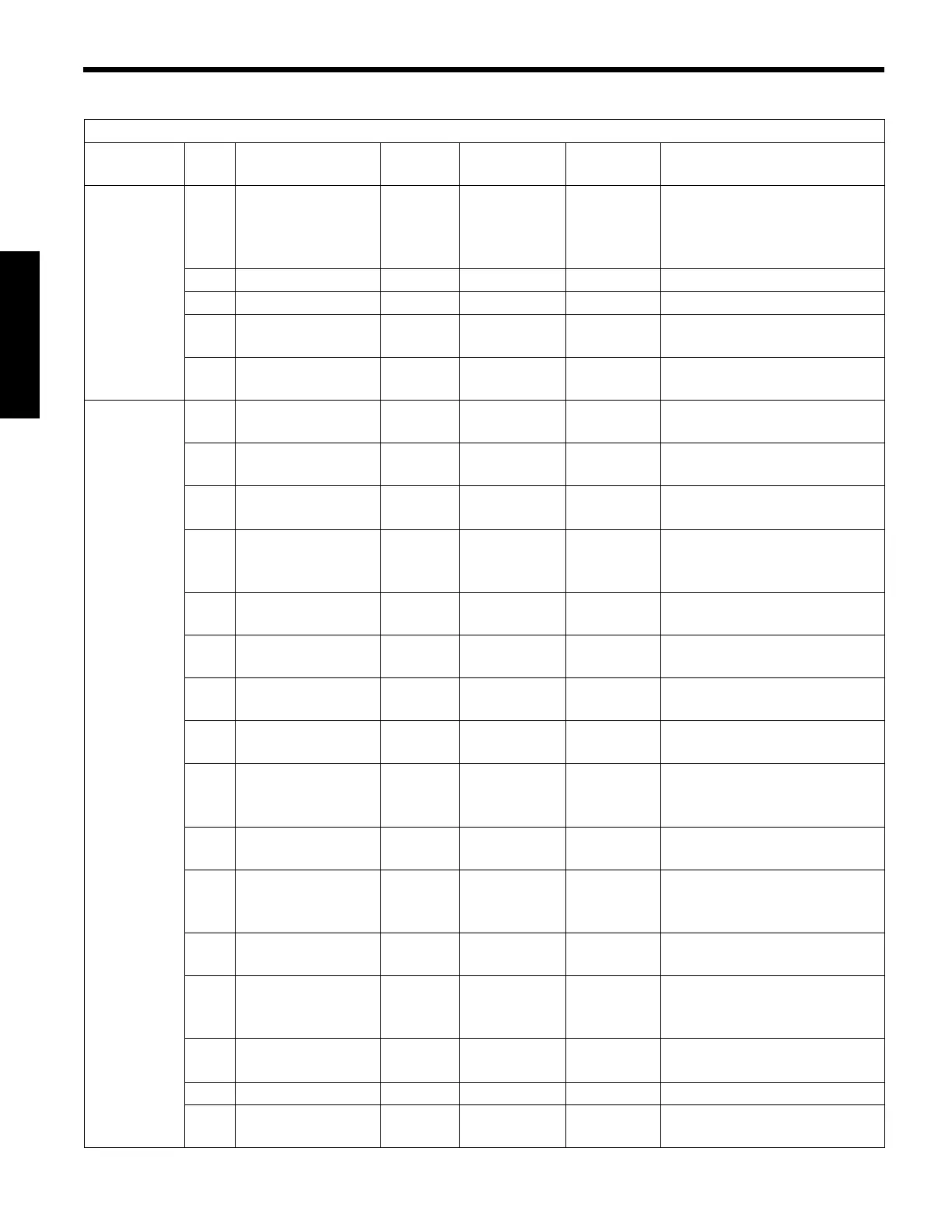

LUBRICATION / FLUID LEVEL CHECK - 65ET T4 FINAL

Interval

Hours

Ref Identification

No. of

Pts

Type of

Lube

Qty Remarks

Every 10

Hours or

Daily

1 Fuel Tank

Ultra Low

Sulfur

Diesel

(ULSD)

Fill

2 DEF Tank ISO 22241 Fill

3 Hydraulic Oil ISO 68 Check sight gauge

4

Transmission

Oil

Engine

Oil

Check dipstick

5

Radiator

Coolant

Check level and mixture

Every 50

Hours or

Weekly

6

Front Axle Drag

Link

2EPG

2-4

Shots

One each side of front

axle.

7

Moldboard Lift

Cylinder Balls

4EPG

2-4

Shots

One on lower end of each

lift cylinder.

8

Circle Shift

Cylinder Balls

2EPG

2-4

Shots

One on each end of circle

shift cylinder.

9

Draw Bar Pivot

Pins

3EPG

2-4

Shots

One on each side of

horizontal pin. One on top

of twist pin.

10

Front Axle Pivot

Pin

1EPG

2-4

Shots

One on axle pivot pin.

11

Steering

Cylinder

2EPG

2-4

Shots

One on each end of

steering cylinder.

12

Front Axle

Knuckle Pivot

2EPG

2-4

Shots

One on each front axle

knuckle pivot.

13

Front Axle

Spindle Pivot

2EPG

2-4

Shots

One on each front axle

spindle pivot.

14

Front Wheel

Lean Cylinder

4EPG

2-4

Shots

One on each end of wheel

lean cylinder. One on each

end of connecting rod.

15

Steering Tie

Rod Ends

2EPG

2-4

Shots

One each end of tie rod.

16

Moldboard Pitch

Adjustment

2EPG

2-4

Shots

One on each end of

moldboard pitch cylinder

or adjuster rod.

17

Implement Lift

Cylinders

4 - 8 EPG

2-4

Shots

One on each end of any

implement installed.

18

Articulation

Joint Bearings

4EPG

2-4

Shots

One on right side of upper

and lower articulation

joints.

19

Articulation

Cylinders

4EPG

2-4

Shots

One on each end of both

articulation cylinders.

20 Circle Turn 1GraphiteA/RLubricate and clean.

21

Moldboard Slide

Bars

2GraphiteA/RLubricate and clean.

Loading...

Loading...