NORAM 65ET GRADER

4-13

Lubrication and Maintenance - Grader Components

4

Every 10 Hours or Daily

EVERY 10 HOURS OR DAILY

Fuel - Check / Add

• DO NOT smoke around diesel fuel.

• DO NOT add gasoline, alcohol, gasohol or dieselhol (a mixture of diesel fuel and alcohol) to die-

sel fuel because of increased fire or explosion risks. In a closed container, such as a fuel tank,

they are more explosive than pure gasoline.

• DO NOT use these blends. Additionally, dieselhol is not approved due to possible inadequate

lubrication of the fuel injection system.

• Clean filler cap area and keep free of debris.

• DO NOT fill tank to capacity, allow room for expansion.

• If original fuel tank cap is lost, replace it with a new cap and tighten securely.

• Wipe up spilled fuel immediately.

• The quality of the fuel used is important to maintaining a dependable machine. Fuels must be

clean, well-refined and noncorrosive to fuel system parts.

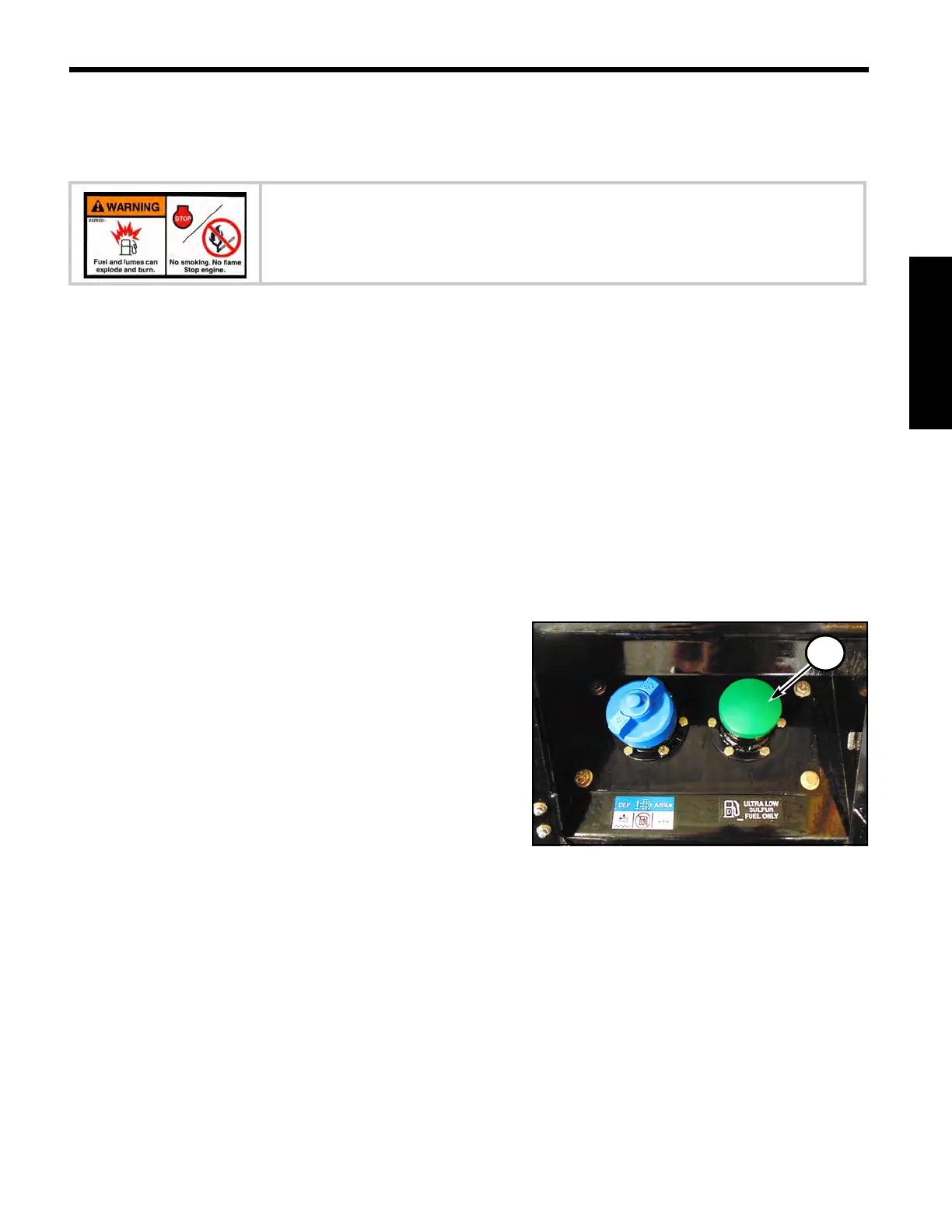

Open access door on left side of machine to add fuel.

Clean area around fuel cap

(1). After filling tank, replace

and tighten fuel cap.

NOTICE: The use of ultra-low sulfur fuel (15 ppm) is

required.

Fuel and fumes can explode and burn.

Shut off engine before refueling. No flame. No smoking.

Loading...

Loading...