Installation, Operation and Maintenance Manual

23

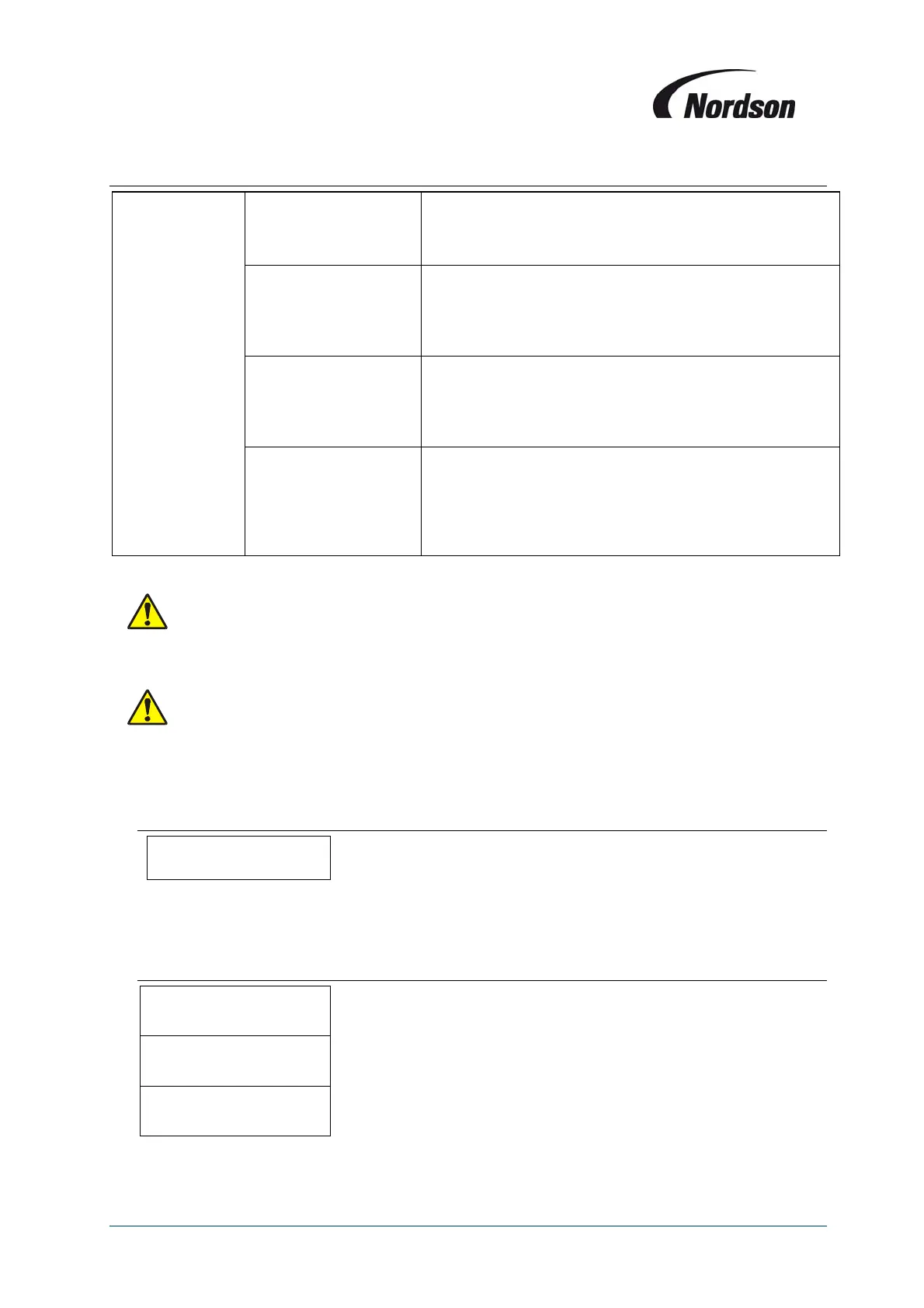

7.15. P22 Delta P Cleaning mode

Delta P Cleaning

mode

DP_CLEAN_MODE___

P22_0_CONT_CLEAN_

Cleaning is not influenced by the differential pressure

measurement, but instead the valves will pulse

continuously. Differential pressure measurement and

monitorin

are activated.

DP_CLEAN_MODE___

P22_1_STOP_&_GO

Cleaning is carried out based on the differential pressure

measurement. On a cleaning stop command, the valve

number of the last activated valve is stored. On the next

cleaning start command, cleaning begins with the valve

with the next hi

her valve number.

DP_CLEAN_MODE___

P22_2_STOP_&_END

Cleaning is carried out based on the differential pressure

measurement. On a cleaning stop command, cleaning

remains active until a full cycle is completed. On the next

cleaning start command, the cleaning begins with the

first valve. This is used as default settin

.

DP_CLEAN_MODE___

P22_3_OFF_LINE_

Only differential pressure measurement and monitoring

are activated. All cleaning control functions based on

Delta P are deactivated. The only cleaning option is now

Off-Line Cleaning according the number of cycles

defined in parameter P06 or via an external command

on input I1 or I2.

When off line cleaning is activated (option 3), make sure that parameter P06 (number of off-

line cleaning cycles) is not set to zero. Otherwise the unit will never start to pulse clean the

filter elements.

Multi fan ECB units operating with Explosive powder will only clean off-line and P22

parameter has no effect. A number of offline clean cycles must be set – otherwise cleaning

will not be initiated.

7.16. P26 Number of valves

NUMBER_VALVES___

P26___XXX_VALVES

Configuration of the number of valves connected to the controller. When the controller starts, all

valves are addressed and checked. If a valve has failed, it is skipped.

7.17. P40 Time/Date Display

T/D_DISPLAY_____

P40_A__AUTOMATIC

T/D_DISPLAY_____

P40_0S_____FIXED

T/D_DISPLAY_____

P40_0W_____FIXED

Loading...

Loading...