Installation, Operation and Maintenance Manual

27

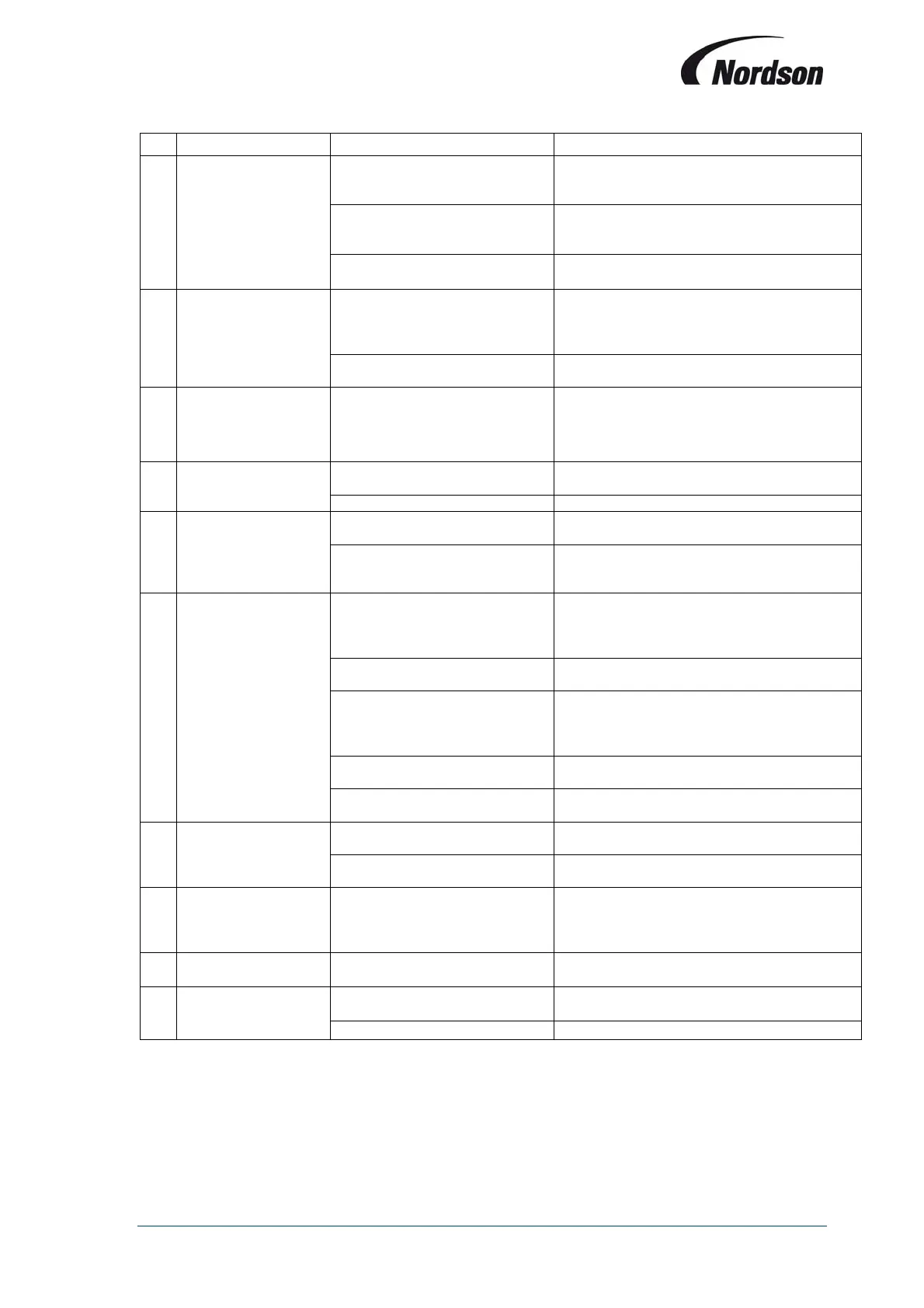

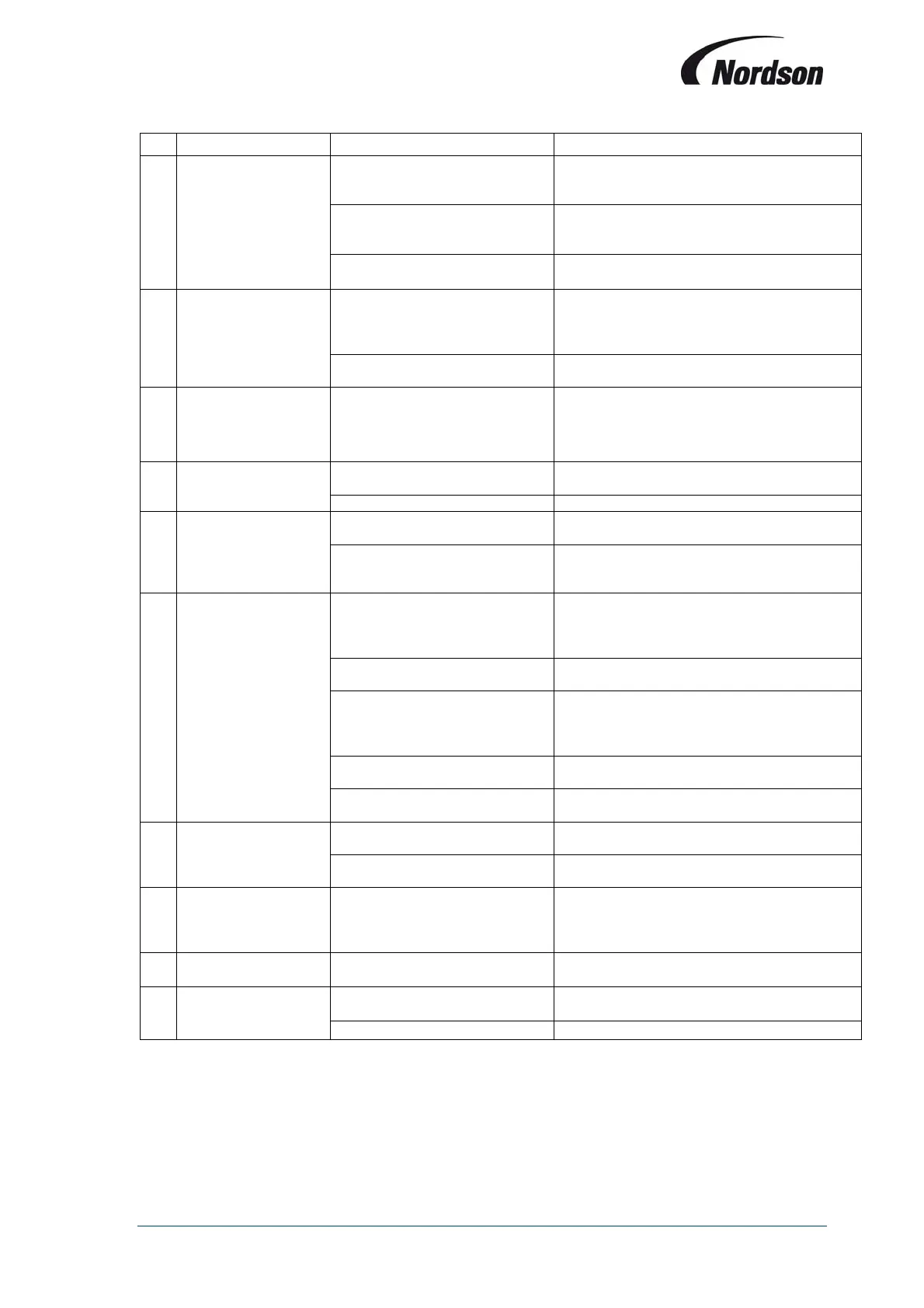

Symptom Possible cause Action

A

Green power-on LED

on module PCB not

illuminated.

Electrical supply fault.

Check supply circuit for proper voltage, fuses,

circuit breakers etc. Replace as required.

Fuse on PCB module blown.

Check wiring connections and replace fuse

with correct type (refer to chapter 11:

Maintenance).

Internal controller failure.

Replace PCB.

B

Fan does not start

and LED ‘Fan on’

(item 7 fig. 1) is not

illuminated.

Main switch on control box open Turn main switch to ON-position.

Electrical supply fault

Check supply circuit for proper voltage, fuses,

circuit breakers etc. Replace as required.

C

The control board is

operational, but the

fan does not start. No

failure is indicated.

Blown fuse

Check the circuit and change fuse F3 (see

wiring diagram supplied with TCB).

D

The automatic circuit

breaker switches off

while the fan starts-up

Delay time between star and

triangle is too short.

Increase change-over time (see chapter 7.7)

Incorrect fan overload setting Check fan overload setting

E

The fan only works in

star operation when

the unit is switched

on; in triangle the fan

stops.

Contactor K2 defective.

Change contactor K2 (see wiring diagram

supplied with TCB)

Incorrect wiring to fan Check wiring from TCB to fan

F

No cleaning pulses

but the LED ‘Pulse

cleaning’ (item 7, fig.

1) is blinking.

Low supply voltage.

Check supply voltage (a low voltage will not

open valves but may operate LED’s normally).

Lack of compressed air for

cleaning.

Increase compressed air pressure for manifold

to 6

7 bar.

Solenoid valves not connected

correctly.

Check connections to solenoid valves in

enclosure or external valve enclosures. Ensure

connection plug is correctly engaged in PCB

socket.

Solenoid valve failure

Check for proper valve action and repair or

replace if necessary.

Diaphragm valve failure

Check for proper valve action and repair or

replace if necessary

G No off-line cleaning.

Off-line cleaning not activated.

Set up controller to off-line cleaning mode

(refer to chapter 7.15).

Off-line cleaning cycles set to ‘0’

Increase number of off-line cleaning cycles

(refer to chapter 7.6)

H

Incorrect/gaps in

valve firing sequence.

Solenoid valves not connected

correctly.

Check connections to solenoid valves in

enclosure or external valve enclosures. Ensure

connection plug is correctly engaged in PCB

socket.

I

Incorrect reading.

Loose connections on

pressure lines.

Check connections for leaks.

J

Incorrect 4-20mA

output.

External circuit resistance too

high.

Reduce external circuit resistance

(recommended range 150-250).

problem

Refer to section I of Fault Location Table.

Loading...

Loading...