G6RA, G6RK Service Manual 9

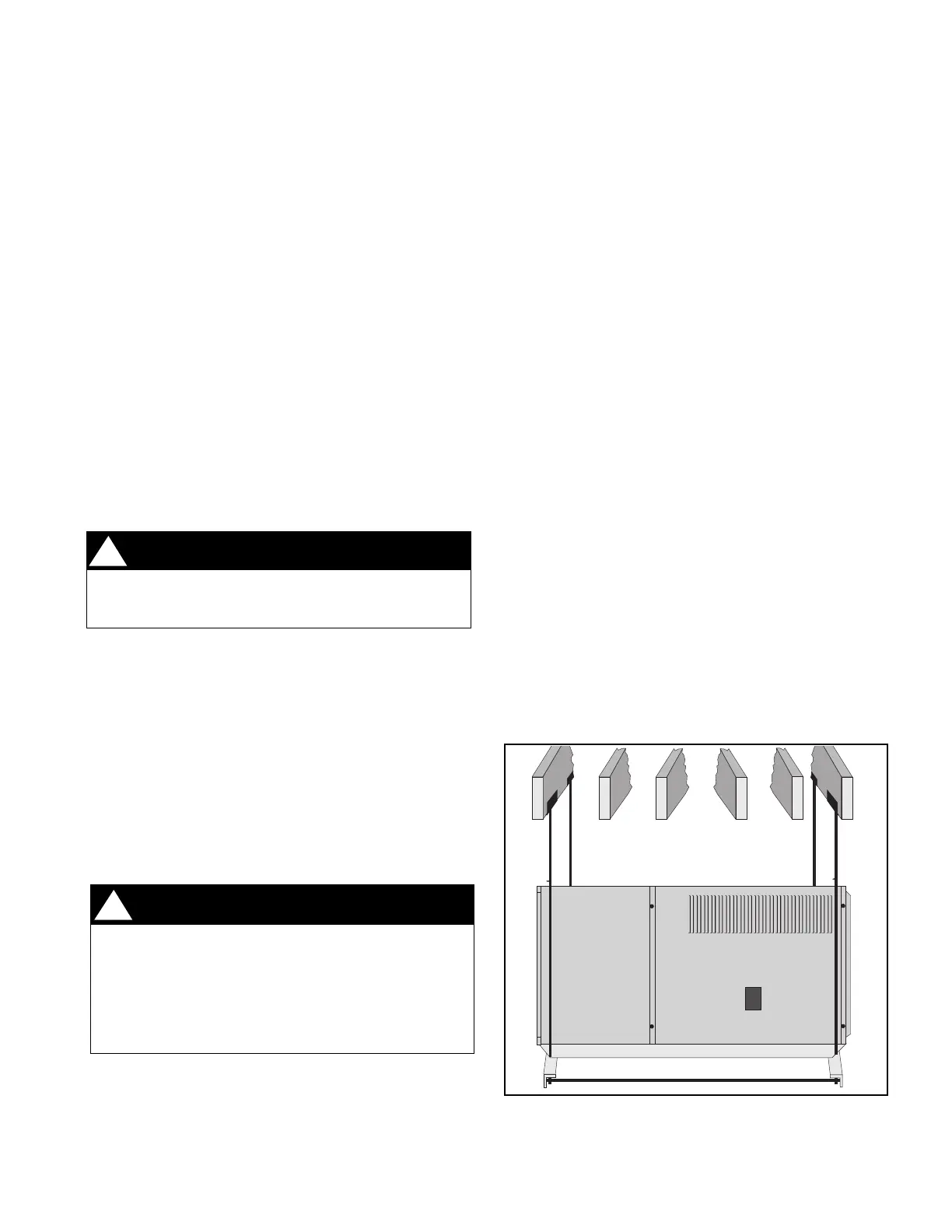

Figure 1. G6RA Horizontal Installation

Suspended in Attic or Crawl Space

Combustion air must not be drawn from a

corrosive atmosphere.

CAUTION:

!

WARNING:

Furnace installation using methods other

than those described in the following

sections must comply with the National Fuel

Gas Code and all applicable local codes to

provide sufficient combustion air for the

furnace.

!

VENTING AND COMBUSTION

AIR REQUIREMENTS

General

Provisions must be made in the installation of this furnace to

provide an adequate supply of air for combustion. Detailed

instructions for determining the adequacy of an installation

can be found in the current revision of the National Fuel Gas

Code (ANSI Z223.1 / NFPA54) or in applicable local building

codes. Consult local codes for special requirements. For

Canadian installations consult Canadian Installations Codes

and (CAN/CGA B149.1 or .2).

If the furnace is operated with inadequate air for combustion

one of the flame roll-out switches located in the burner

compartment or the vent switch will open, turning off the gas

supply to the burners. These safety devices are manually

reset switches. DO NOT install jumper wires across these

switches to defeat their function. DO NOT reset a switch

without identifying and correcting the fault condition. If a

switch must be replaced, use only the correct part specified

in the Replacement Parts List.

Air openings in the furnace door, warm air registers, and

return air grilles must not be restricted.

To maximize heat exchanger life, the combustion air must be

free of chemicals which form corrosive acidic compounds in

the combustion gases. Some examples of these chemicals

are chlorine, fluorine, and sulphur. Some common sources

of these chemicals are detergents, bleaches, aerosol sprays,

cleaning solvents, and a wide variety of commercial and

household products.

When installing a furnace in a commercial building or in a

laundry room or workshop of a residence, it may be necessary

to provide outside air to the furnace for combustion.

Installation In An Unconfined Space

An unconfined space is an area including all rooms not

separated by doors with a volume greater than 50 cubic feet

per 1,000 Btuh of the combined input rates of all appliances

which draw combustion air from that space.

For example, a space including a water heater rated at 45,000

Btuh input and a furnace rated at 75,000 Btuh requires a

volume of 6,000 cubic feet [50 x (45 + 75) = 6,000] to be

considered unconfined. If the space has an 8 foot ceiling, the

floor area of the space must be 750 square feet (6,000 / 8 =

750). In general, a furnace installed in an unconfined space

will not require outside air for combustion. However, in “tight”

buildings (with weather stripping and caulk to reduce infiltration),

it may be necessary to provide outside air to ensure adequate

combustion and venting, even though the furnace is located

in an unconfined space.

Installation In A Confined Space

A confined space is an area with volume less than 50 cubic

feet per 1,000 Btuh of the combined input rates of all

appliances drawing combustion air from that space. Furnace

closets, small equipment rooms and garages are confined

spaces. Furnaces installed in a confined space which supply

heated air to areas outside the space must draw return air

from outside the space and must have the return air ducts

tightly sealed to the furnace. A confined space must have

two openings into the space for combustion air. One

opening must be within 12 inches of the ceiling, and the

other must be within 12 inches of the floor. The required

sizing of these openings is determined by whether inside or

outside air is used to support combustion, the method by

which the air is brought to the space, and by the total input

rate of all appliances in the space.

Horizontal Furnace Installation

The G6RA can be installed horizontally in an attic, basement,

crawl space or alcove. It can be suspended from a ceiling in

a basement or utility room in either a right to left airflow or left

to right airflow. (See Figures 1 and 2.)

Loading...

Loading...