G6RA, G6RK Service Manual 13

Cover

Plate

Nut

Covered Vent

Collar Hole

Looking Down at

Vent Opening

Figure 8. G6RA Bleed Tube Installation

Figure 9. G6RA Vent Collar Detail

The venting system should be designed to have the minimum

number of elbows or turns. All horizontal runs shall be

sloped upwards from the furnace at 1/4 inch per running foot

of vent. Supports for the vent pipe must be installed a

minimum of every five feet along the vent run to ensure no

displacement after installation.

Under no circumstances shall any portion of the vent system

extend into or pass through any return air duct, supply air

duct, or plenum.

If the furnace is operated with blocked or restricted venting,

the blocked vent switch located in the vent plate will open,

turning off the gas supply to the burners. The blocked vent

switch is a manually reset device. DO NOT install a jumper

wire across this switch to defeat its function. DO NOT reset

the switch without identifying and correcting the fault condition

which caused the switch to trip. If this switch must be

replaced, use only the part specified in the Replacement

Parts List.

Category III - Horizontal Venting

NOTE: The reduced NOx models (eighth character N) are not

approved as a Category III (Categorie III) furnace for use with

horizontal venting.

The furnaces are approved for use with 3" single wall AL29-

4C stainless steel vent pipe in horizontal vent applications.

This pipe is available from the following manufacturers:

Z-FLEX Inc. - vent brand name (Z-VENT)

Heat-fab Inc. - vent brand name (Saf-T Vent)

Flex-L International - vent brand name (Star-34 Vent)

This vent pipe must be used for the entire length of the vent

run. The installation must be in accordance with all instructions

supplied by the vent manufacturer for use on Category III

appliances. When venting horizontally this is a Category III

furnace, the vent pressure is positive, and the venting

system must be sealed.

For horizontal venting installations in both the United States

and Canada the transition assembly must be modified, the

bleed tube must be added to the pressure switch tube, and

the vent switch must be by-passed. The bleed tube is found

in an envelope, attached to the furnace literature.

Horizontal Venting For G6RA Models:

NOTE: An optional horizontal vent kit will be required. See

Vent Kit Bleed Tube Chart on Page 40.

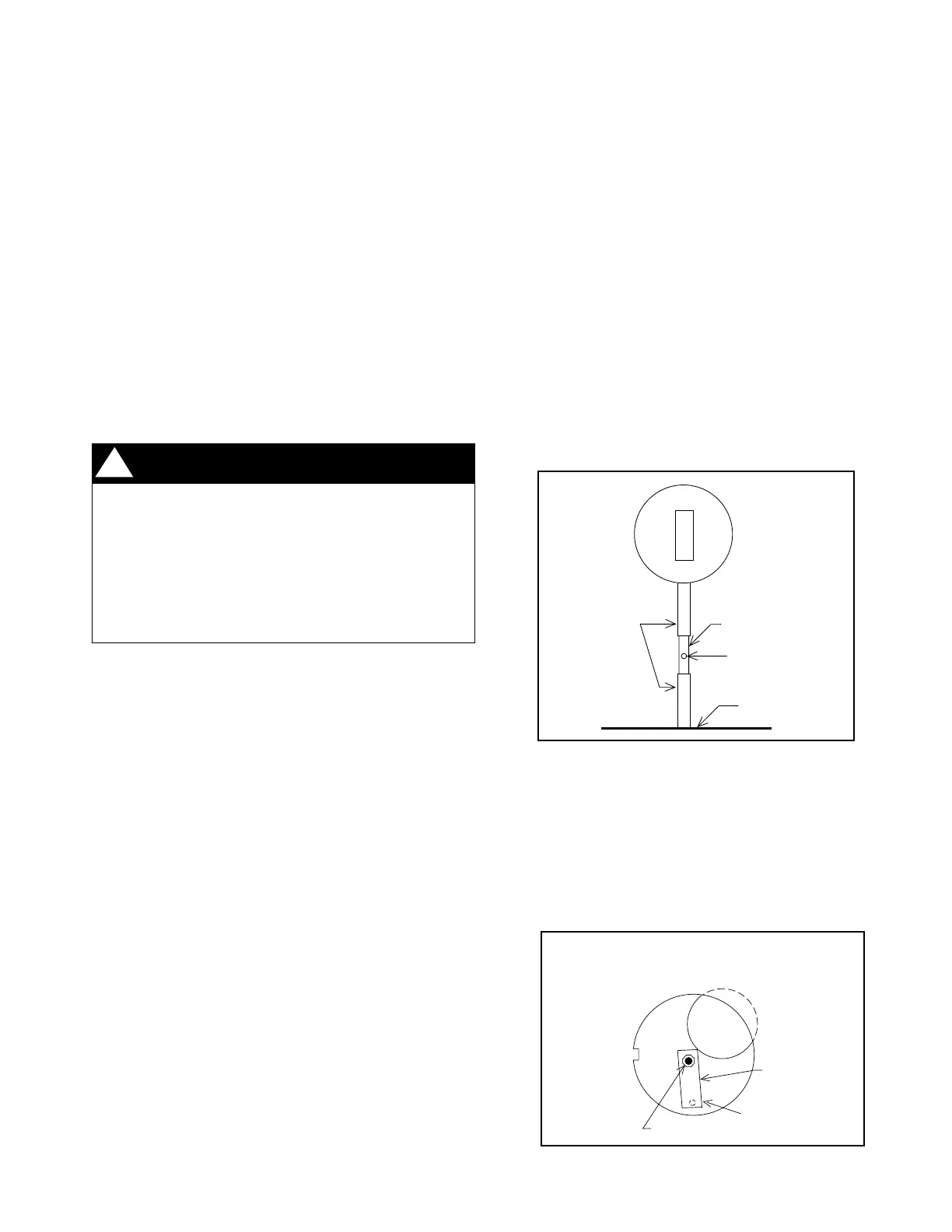

1. Remove the rubber tubing from the pressure switch

sensor tube and the collector pan sensor tube. Cut 1/2

inch from one end of the rubber sensor tube, fold in half

and cut along the bend line. Discard the 1/2 inch long

piece and place the other two pieces on both ends of the

bleed tube, do not cover the hole in the bleed tube. Place

the assembly back on the pressure switch sensor tube

and the collector pan sensor tube.

(See Figure 8.)

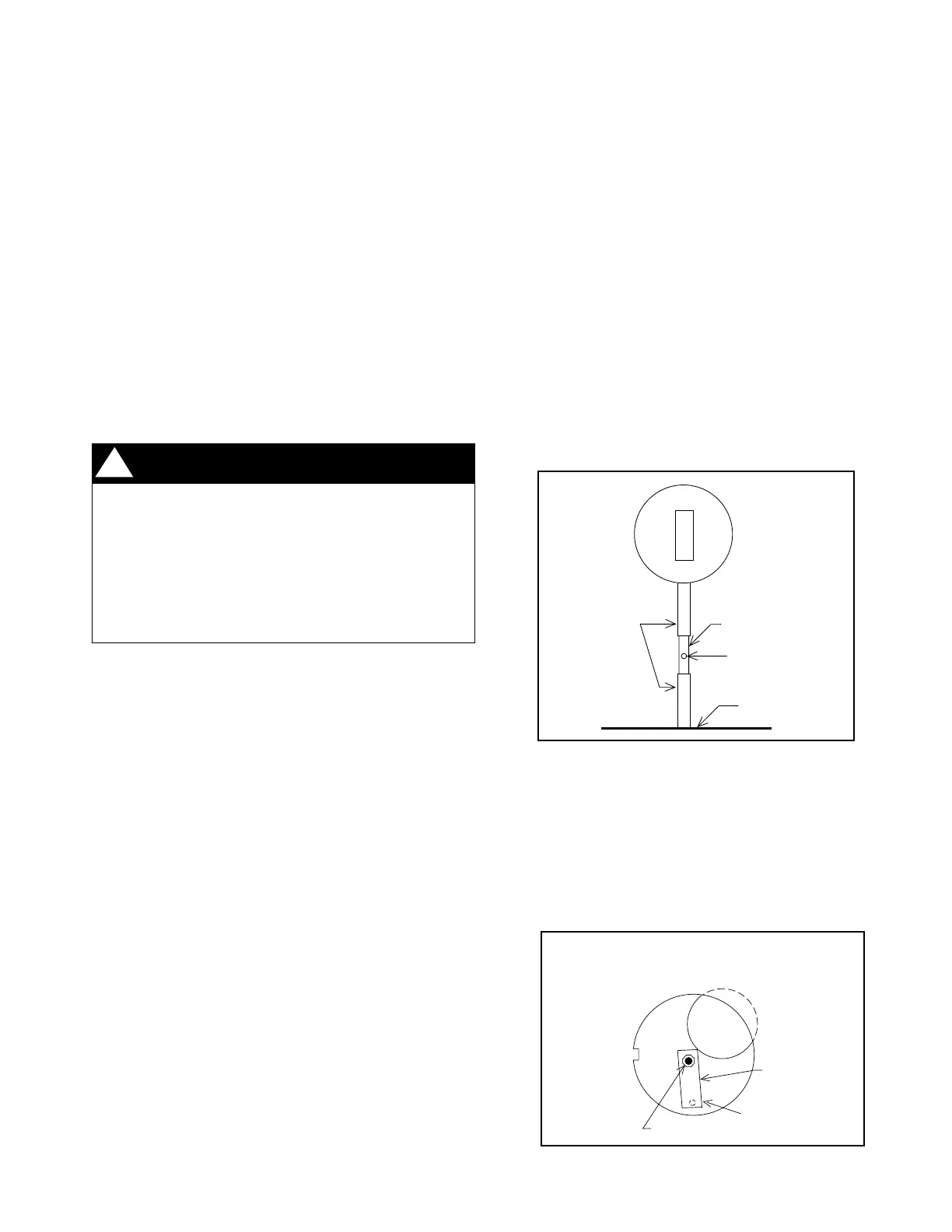

2. Remove the nut and restrictor plate from the vent collar

assembly and discard the restrictor plate. Remove the

cover plate from the envelope attached to the furnace

literature, and fit the clearance hole over the weld stud.

The cover plate must cover the hole(s) on the vent collar

assembly. Tighten the nut securely while holding the

cover plate in position. (See Figure 9.)

3. Bypass the vent switch by removing both wires from

the vent switch and attaching them to the wire nut.

(See Figure 10.)

Horizontal Venting For G6RK Models:

NOTE: An optional horizontal vent kit will be required. See

Vent Kit Bleed Tube Chart on Page 40.

Collector

Pan

Pressure

Switch

Cut

Sensor

Tubes

Bleed Tube

Bleed Tube

Orifice

WARNING:

Upon completion of the furnace installation,

carefully inspect the entire flue system both

inside and outside the furnace to assure it is

properly sealed. Leaks in the flue system can

result in serious personal injury or death due

to exposure of flue products, including

carbon monoxide.

!

Loading...

Loading...