30 G6RA, G6RK Service Manual

Roll Out Limit Control (See Figure 36)

The function of a roll out switch is to sense any flames

backing out of the heat exchanger tubes. They are normally

closed and are manually reset.

Check-out Procedure:

1. Shut off power supply to furnace.

2. Remove wires from roll out switch.

3. Using an ohmmeter, check out continuity across switch.

4. An infinite reading indicates an open switch.

5. Depress reset button to reset switch.

6. Continuity or 0 ohms should now be read. If not, replace

switch.

Possible causes of roll out switches tripping:

1. Blocked heat exchanger (sooted)

2. Loose heat exchanger tube

3. Burner misaligned

4. Supply air interfering with flame patterns

5. Overfiring/too high gas pressure

6. Insufficient combustion air

Draft Inducer Motor (See Figure 37.)

All models use an induced draft combustion blower mounted

on the outlet of the heat exchanger. Its purpose is to establish

a draft (flow) through the heat exchanger, to insure that all flue

products are carried outside the structure via the vent pipe.

(See Figure 40.) The blower is driven by a 115V permanent

split capacitor motor. The same (part #) blower is used on all

models of all series.

Check-out Procedure:

1. Disconnect Molex plug between control board and motor.

2. Using the appropriate scale on a volt meter, insert probes

into plug coming from control board.

3. Establish call for heat.

4. If voltage is read, check fan capacitor. If fan capacitor is

okay, replace motor. (See Figure 38.)

5. If no voltage is read, replace control.

6. Check for debris in wheel preventing it from turning.

Figure 37.

Figure 38.

Figure 39.

Figure 36.

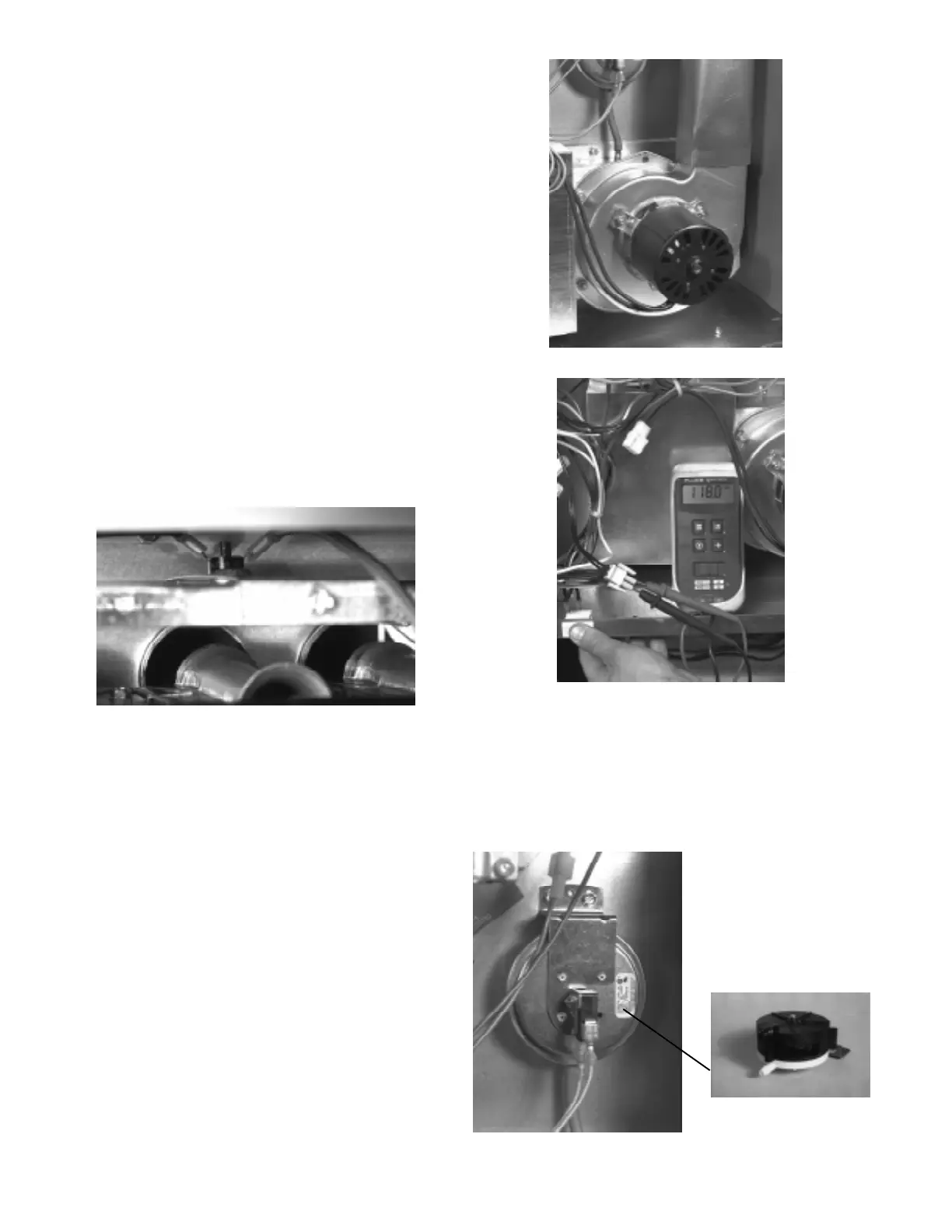

Pressure Switch

The pressure switch verifies that the inducer is drawing the

combustion gases through the heat exchanger. (Figure 39.)

Loading...

Loading...