17

Downflow Furnaces

WARNING:

Thefurnacemustnotbeinstalleddirectlyon

carpeting,tile,oranycombustiblematerialother

thanwoodooring.

WARNING:

Failuretoinstallthedownowsub-basekitmay

resultinre,propertydamageorpersonalinjury.

To install the furnace on combustible flooring, a special

sub-base is required. Downflow sub-base kits are factory

supplied accessories and are listed according to the cabinet

letter of the furnace. For ‘B’, ‘C’, and ‘D’ size cabinets use

Kit #904911. Pleasefollowtheinstructionsprovided

withthekit.

A downflow sub-base kit is not necessary if the furnace

is installed on a factory or site-built cased air conditioning

coil. However, the plenum attached to the coil casing

must be installed so that its surfaces are at least 1” from

combustible construction.

Installation on a concrete slab

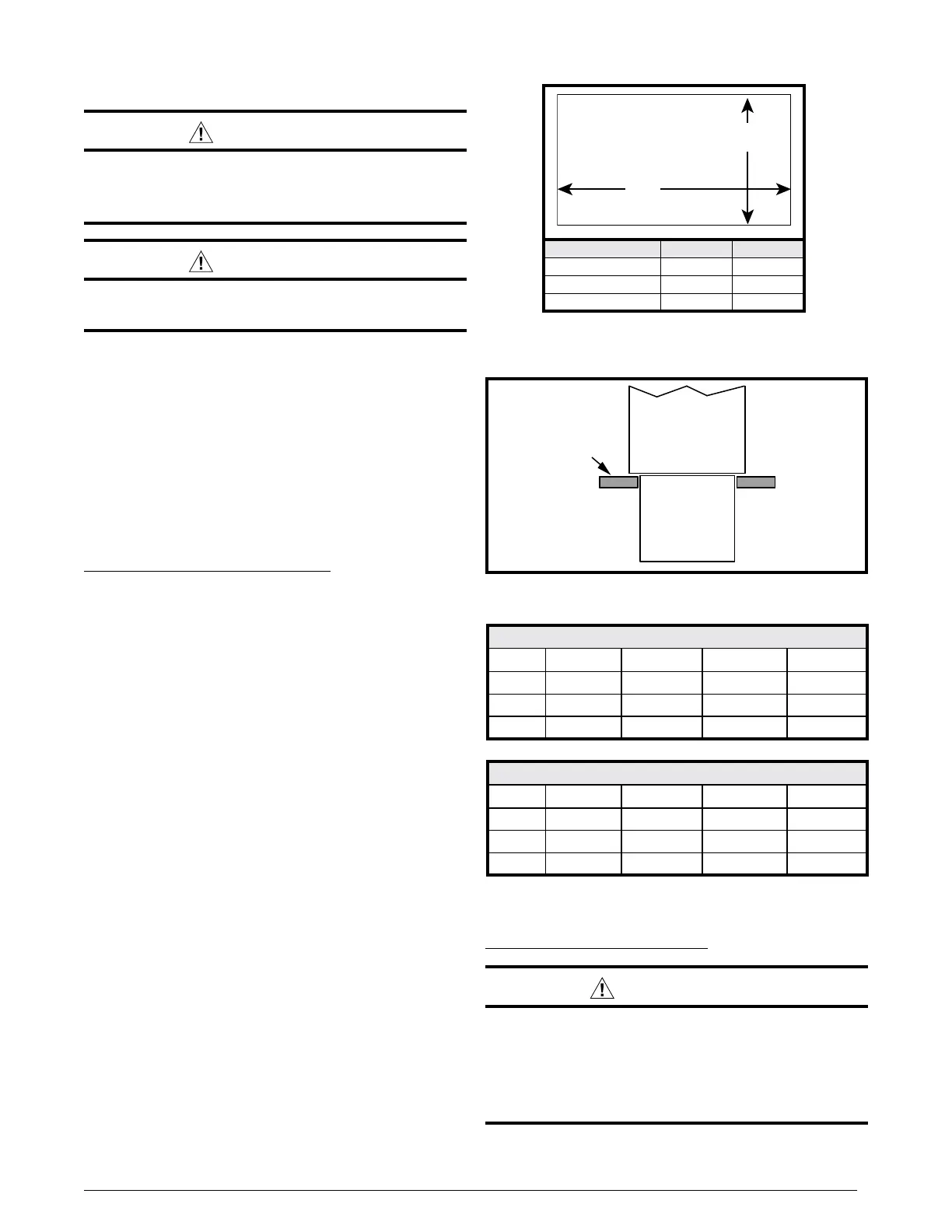

1. Create an opening in the floor according to the

dimensions in Table 3.

2. Position the plenum and the furnace as shown in

Figure 13.

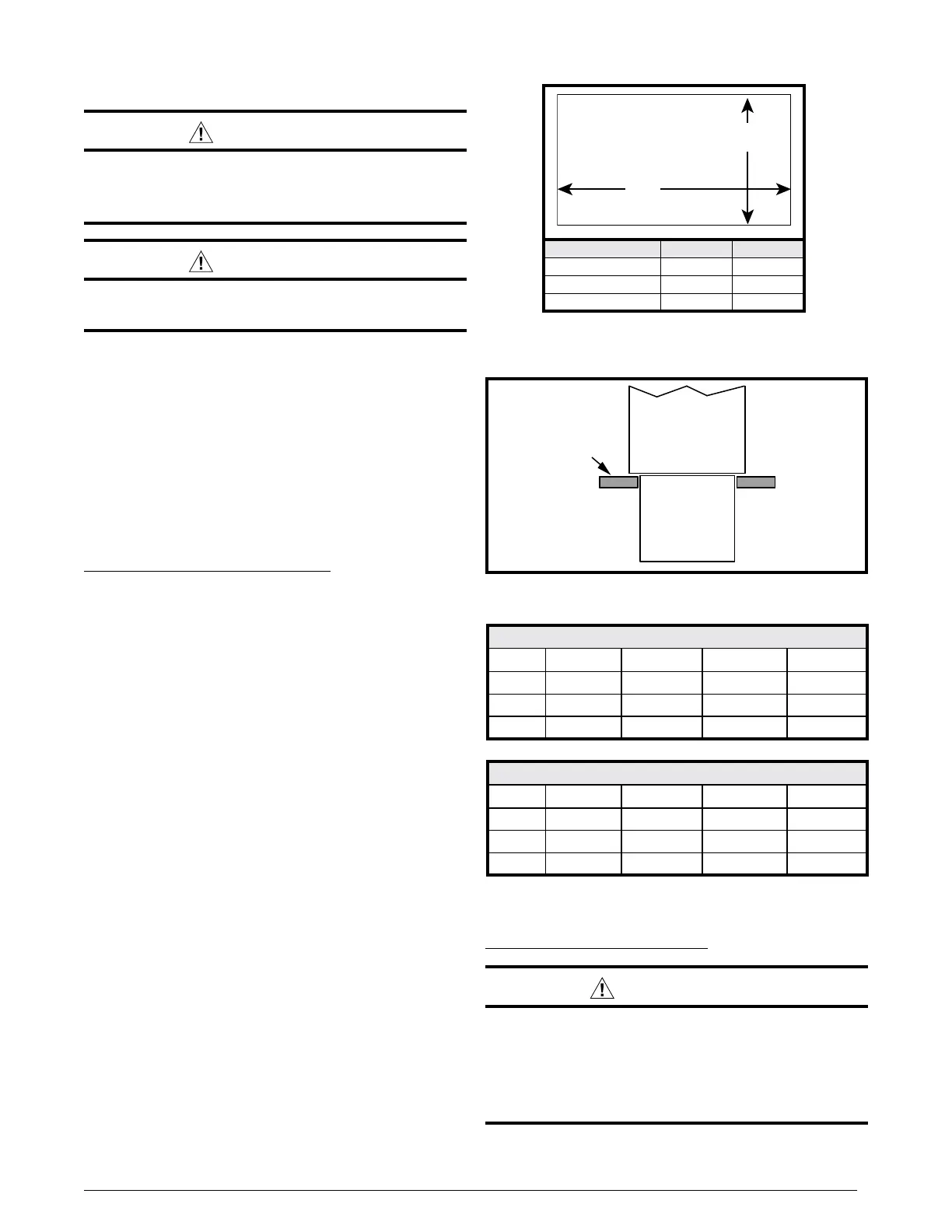

Inducer & Venting Options

To increase installation flexibility, the inducer assembly

can be rotated to 2 different positions. Each variation has

slightly different requirements with regard to condensate

disposal and, in some cases, the need to seal the furnace

cabinet.

IMPORTANT NOTE

TheInducerAssemblymustneverbepositionedto

ventdownwardsonhorizontalinstalls.

Before using Table 4, the number of pipes (1-pipe or 2-pipe)

connected to the furnace must be known. Find the proper

furnace style (upflow, horizontal, or downflow) and then

the side that the pipes will exit from the furnace. Finally

select the option that properly matches your installation

type from Figure 37 (page 46), Figure 38 (page 47),

or Figure 39 (page 48).

NOTE: It is important that Direct Vent (2-pipe) systems

maintain an airtight flow path from the air inlet to the flue

gas outlet. The furnace ships from the factory with two

holes in the cabinet for the air inlet and flue gas outlet.

In certain configurations, it is necessary to remove and

relocate a plastic cap in the furnace cabinet. If changing

the position of the air inlet and flue gas outlet, it is required

that the previous hole be closed off with the plastic cap to

maintain air tightness in the furnace. The hole locations for

*TC & *TL furnaces are shown in Figure 28 (page 32).

Inducer Assembly Rotation

WARNING:

Inducer rotation must be completed before

thefurnaceisconnectedtogasandelectric.If

bothutilitieshavebeenconnected,followthe

shutdownproceduresprintedonthefurnace

labelanddisconnecttheelectricalsupply.

Concrete

Floor

Furnace

Sheet

Metal

Plenum

Figure13.Furnace on a Concrete Slab

Table3.CutoutDimensions

Cabinet Size Dim.“A” Dim.“B”

B 16 5/8 19 1/4

C 20 1/8 19 1/4

D 23 5/8 19 1/4

NOTE: Dimensions shown in Inches.

“A”

“B”

Opening in concrete floor

Conventional(1Pipe)

Vent Upflow Horiz.Right Horiz.Left Downflow

Right Option 1 N/A N/A Option 9

Up N/A Option 5 Option 6 Option 10

Left Option 2 N/A N/A Option 11

Direct Vent (2-pipe)

Vent Upflow Horiz.Right Horiz.Left Downflow

Right Option 3 N/A N/A Option 12

Up N/A Option 7 Option 8 Option 13

Left Option 4 N/A N/A Option 14

Table4.Vent & Inducer Blower Options

Loading...

Loading...