25

Part 1 - General Safety Information

Part 4 - Water Piping

I. Applications*

G. Air Elimination Device

A micro bubble air elimination device must be installed in every boiler

installation. Automatic air vents alone are not an acceptable substitute

for a micro bubble air elimination device. Here are a few examples of

acceptable devices.

• Spirovent

• TACO 4900 Series

• Cale Discal

In mixed temperature applications, mixing valves are required for the

protection of low temperature loops.

CAUTION

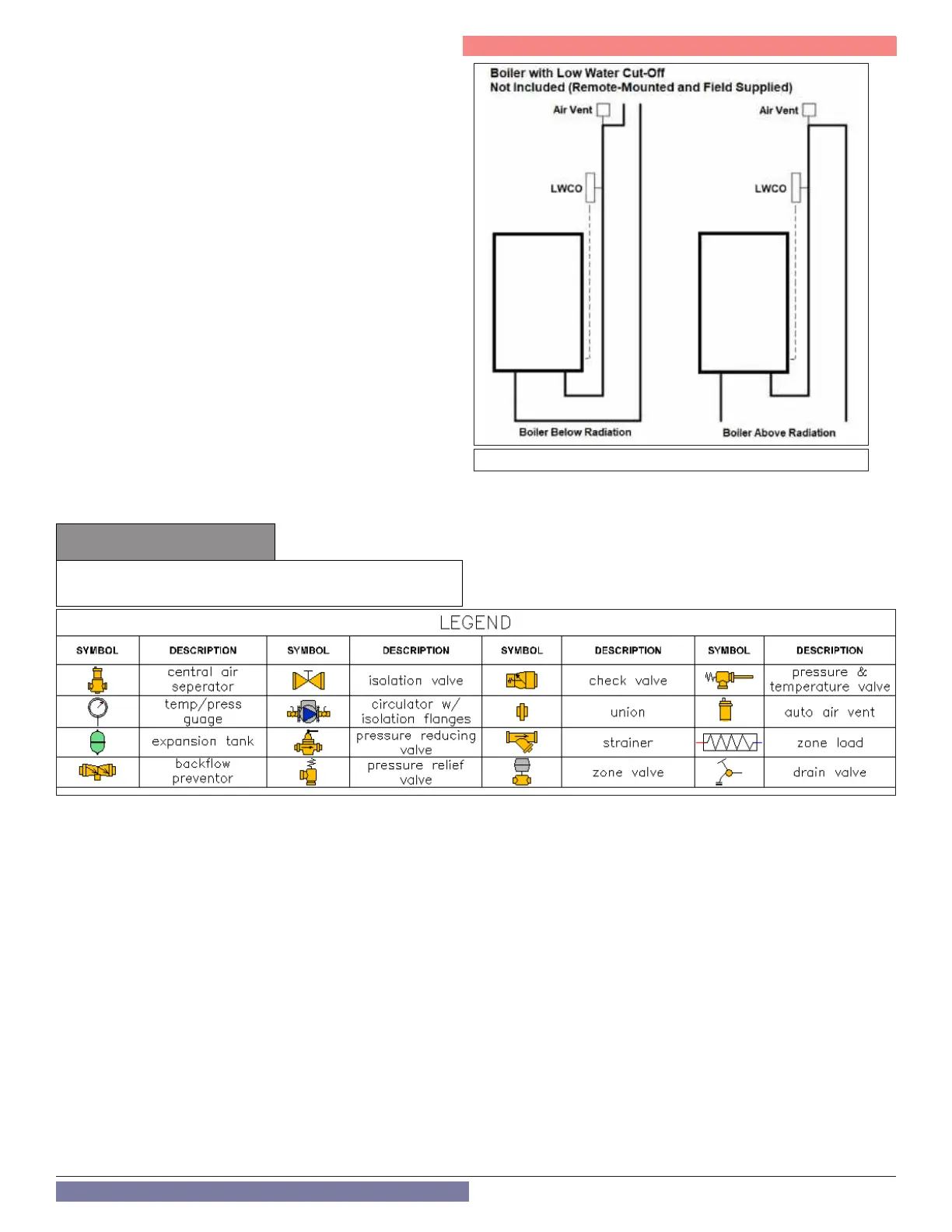

Figure 12 - Low Water Cut-O Basic Installation

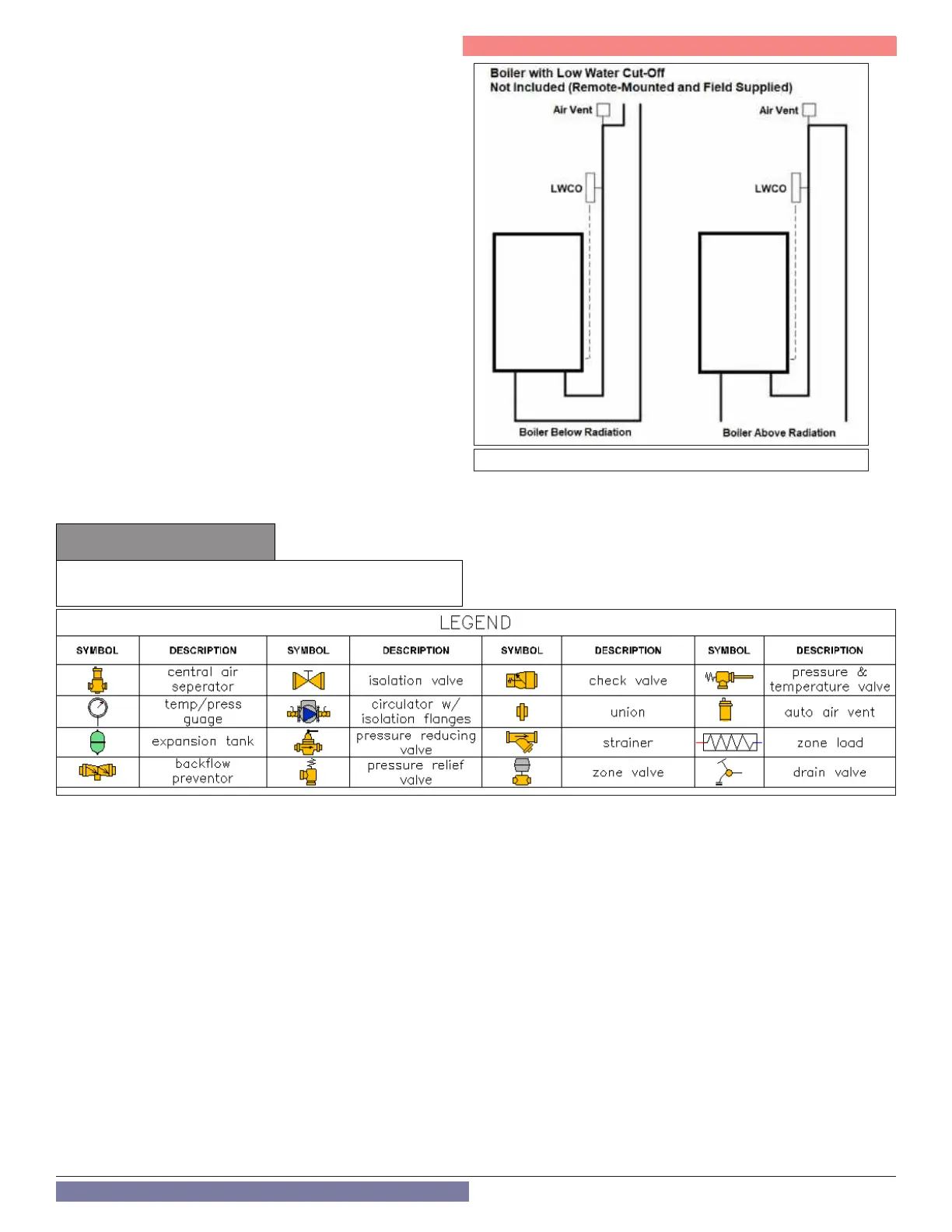

Figure 13 - Piping Symbol Legend

H. Low Water Cut-O (Field Supplied)

This boiler is provided with a factory installed Water Pressure Switch. In the

event water pressure drops below 7 PSI, the control will go to a blocking

error “FILL - 108”, inhibiting burner operation.

However, a low water cut-o may be required by local codes. This is to be

remote-mounted and eld supplied. See Figure 12 for basic Low Water

Cut-O installation instructions. Do not install an isolation valve between

boiler and low water cut-o.

When wiring the low water cut-o follow the installation instructions

provided by the low water cut-o manufacturer.

NOTE: During a low water condition, the eld supplied low water cut-o

normally open contacts must break the main power supply to the boiler.

Failure to follow this instruction will defeat the purpose of a low water cut-

o and will result in damage to the boiler. Such damages are not covered

by boiler warranty.

Loading...

Loading...