82

Part 1 - General Safety Information

A. Boiler Protection Devices

The boiler is protected from malfunctioning by means of internal

checks performed by the electronic microprocessor PCB, which stops

the boiler from operating if necessary. In the event of the boiler being

shut o in this manner, a code appears on the display which refers to

the type of shut-o and the reason behind it.

There are two types of shut-o:

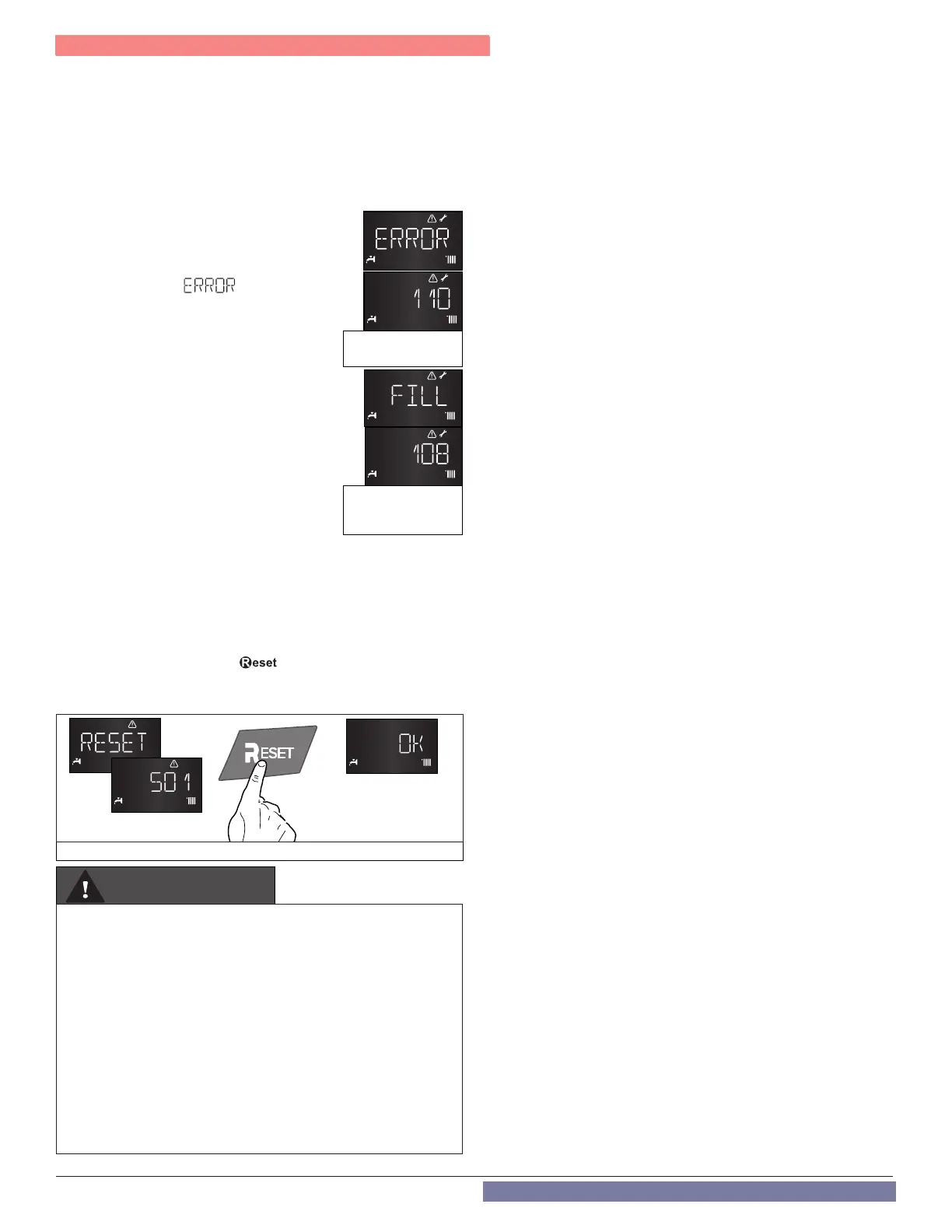

1. Blocking Error

A blocking error means the boiler will restart

automatically as soon as the problem which

caused the error clears or is removed; the error

is indicated by the « » symbol which

appears on the display followed by the error

code.

For example, if the boiler indicates a 110 error

code, the error will clear automatically when

the CH temperature decreases. The boiler will

restart and operate normally.

NOTE: Contact a qualied service technician if

the error continues to occur.

In the event of Error 108 - Shut-o due

to insucient water pressure inside the

heating circuit - Pressure can be increased

by lling the heating circuit. See lling and

purging procedures, this manual.

Figure 78 - Blocking

Error Example

Figure 79 - Shut-O

Error for Low Water

Pressure

Figure 80 - Lockout Error Example

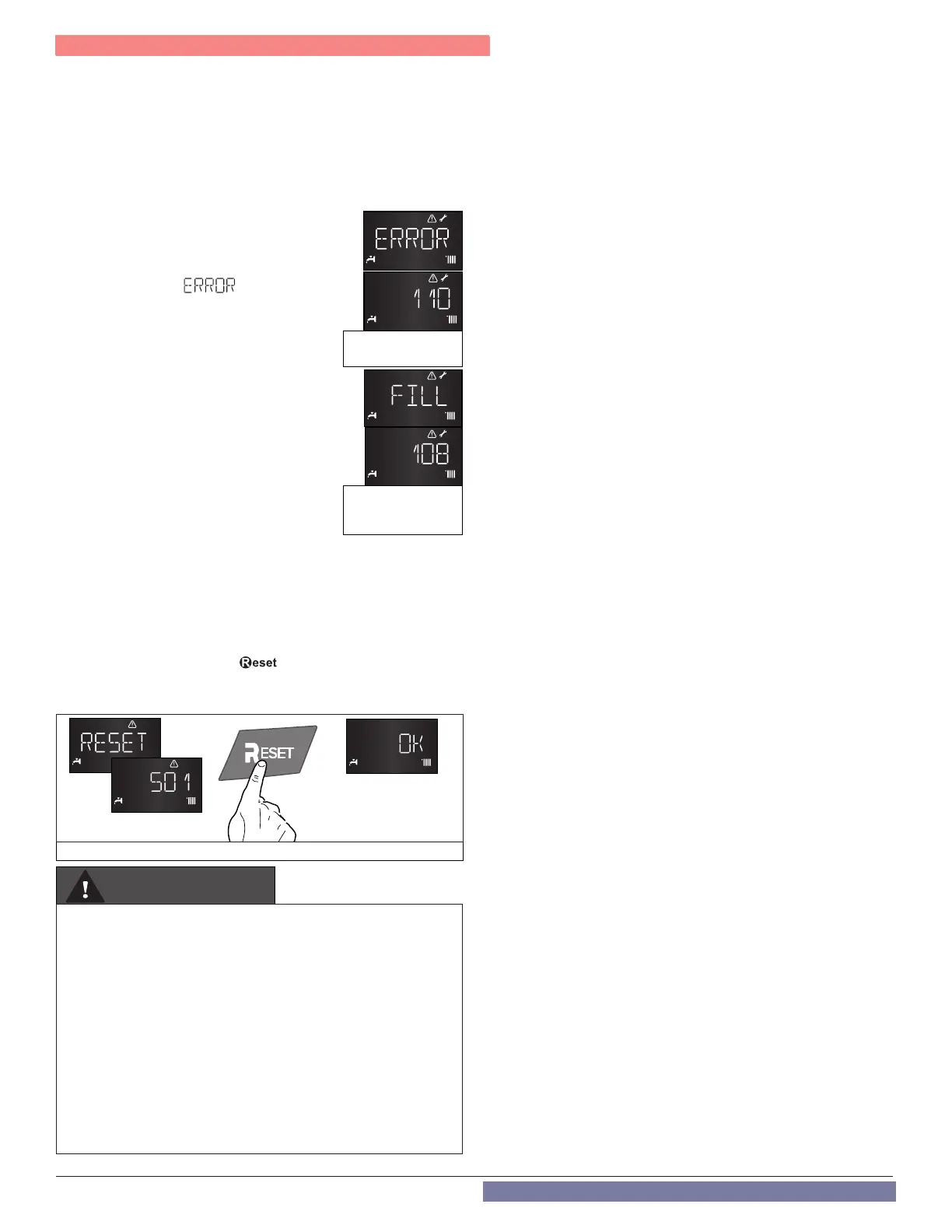

2. Lockout Error

A lockout error means the boiler does not return to operation after the

error condition goes away. The button must be pressed on the

control panel to restore boiler operation.

If the error condition occurs often contact a qualied service technician.

3. Malfunction Warning

This warning is shown by the display in the following format:

5 P1 = FIRST IGNITION ATTEMPT UNSUCCESSFUL

The rst part of the error code (e.g. 1 01) indicates the aected

operational assembly.

1 - Primary Circuit

2 - Domestic Hot Water Circuit

3 - Internal Electronic Part

4 - External Electronic Part

5 - Ignition and Detection

6 - Air inlet - ue gas outlet

7 - Multi-zone Heating

If Error 108 occurs frequently and system needs repeated relling, turn

the boiler o. Turn the external electric power to the OFF position. Shut

o the main gas valve. Contact a qualied service technician to check

for any leaks of water.

WARNING

Important

Contact a qualied service technician for assistance if a

Lockout Error occurs frequently. For safety reasons, the

boiler will permit a maximum of ve (5) resets in 15 minutes

(ve [5] presses of the RESET button). A sixth (6th) attempt

within this 15 minute period will lock out the boiler. The boiler

will only operate again after the electrical supply has been

disconnected and reconnected.

Repeated Lockout Error conditions could indicate a serious

error with the boiler or installation. Failure to contact a

qualied service technician to troubleshoot the error could

result in substantial property damage, serious personal

injury, or death.

Part 13 - Troubleshooting

Loading...

Loading...