88

Part 1 - General Safety Information

Part 14 - Maintenance

C. Maintenance Only to be Performed by a Qualied Service

Technician

Removing the Cabinet Cover and Inspecting the Boiler

Before carrying out any work on the boiler, switch o the power supply

at the external power switch and circuit breaker. Close the external

gas shuto.

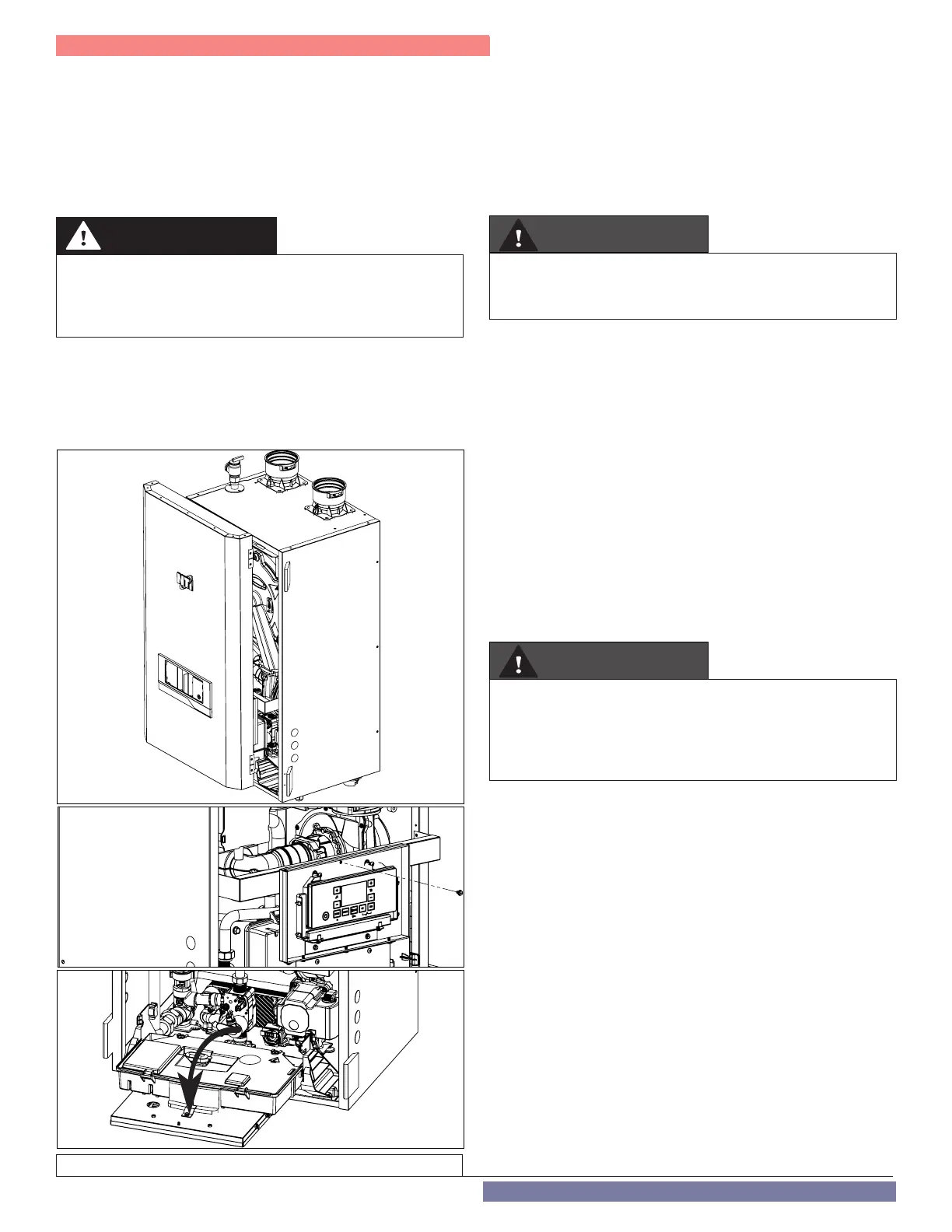

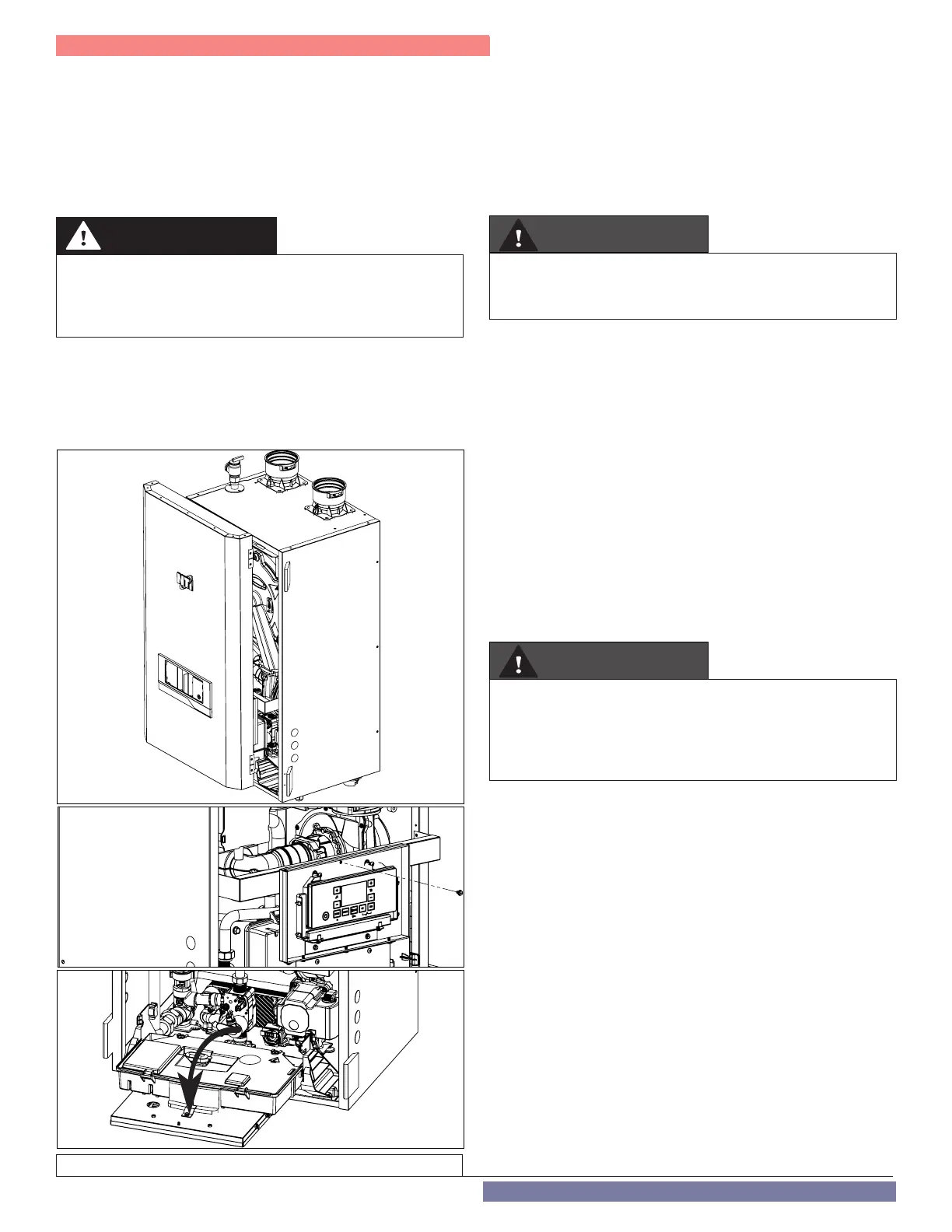

See Figure 81 to access the interior of the boiler:

1. Release the four (4) latches from the front cover (two [2] each

side). Lift and remove the front cover from the cabinet

(a)

.

2. Remove the screw securing the control panel to the cross-member

(b).

3. Push in the tabs and pull the control panel housing forward (c).

Figure 81 - Removing the Cover and Control Panel Housing

Before Starting Maintenance:

1. Ensure the power and gas remain o.

2. Close the valves of heating and hot water circuit.

3. Remove the front panel as shown in Figure 81.

4. If necessary, empty the appliance on the water side.

Draining Procedure

To drain the heating system:

1. Ensure the boiler power and gas remain o.

2. Open the manual purge valve.

3. Open the system drain valve and collect the escaping water in a

container.

4. Drain the water from the lowest points of the system (where

applicable).

If the system is to be inactive in areas where the room temperature

may fall below 0°C during winter, it is recommended that anti-freeze

liquid be added to the heating system in order to avoid the need for

repeated draining. Ensure the antifreeze used is compatible with the

stainless steel boiler heat exchanger.

Check Water and Gas Piping

1. Remove the boiler cover and perform a gas leak inspection following

Operating Instructions on page 2 of this manual. If gas odor or leak

is detected, follow procedures on page 2. Call a qualied service

technician.

2. Visually inspect for leaks around the boiler water connections

and around the heat exchanger. Visually inspect the external

system piping, circulators, and system components and ttings.

Immediately call a qualied service technician to repair any leaks.

It is recommended to use antifreeze which contains PROPYLENE

GLYCOLS as these inhibit corrosion. Use the quantities and formulation

suggested by the antifreeze manufacturer to protect against freezing

in your region and prevent scaling and corrosion.

Regularly check the pH level of the water/anti-freeze mix in the boiler

circuit and replace it when the value measured is lower than the limit

prescribed by the manufacturer.

DO NOT MIX DIFFERENT TYPES OF ANTI-FREEZE.

The manufacturer will not be held liable for any damage caused by

the appliance or the system due to the use of inappropriate antifreeze

substances or additives.

Draining the DHW System and Indirect Water Heater

Every time there is a danger of freezing, the domestic hot water system

must be drained as follows:

1. Shut o the main water inlet valve.

2. Open all the hot and cold water taps.

3. Drain the water from the lowest points of the system.

WARNING

WARNING

Ensure power and gas to the appliance are shut off before

performing the following operations. Failure to do so will

result in substantial property damage, severe personal

injury, or death.

Have leaks xed at once by a qualied service technician.

Failure to comply could result in substantial property

damage, severe personal injury, or death.

NEVER use any toxic chemical, including automotive,

standard glycol antifreeze, or ethylene glycol made for

hydronic (non-potable) systems. These chemicals can

attack gaskets and seals in water systems, are poisonous if

consumed, and can cause personal injury or death.

DANGER

3. If applicable, check the condensate neutralizer and ensure it is full

of condensate neutralizing marble chips.

(b)

(a)

(c)

Loading...

Loading...