77

automatically. This seven (7) minute cycle

removes excess air from the CH and DHW systems.

a. During the cycle open the manual air vent

within the boiler. Close the air vent when clear

water free of air is visible (after purging).

b. As air is purged boiler pressure may drop. The

boiler needs to maintain at least 12-15 psi for proper purging.

NOTE: The water pressure switch safety is set at 8 psi to protect the

boiler. Error 108 will occur if boiler pressure drops too low. After

pressure is restored Error 108 will clear and the boiler will return to the

purge function for another 7 minutes.

c. After the cycle has ended ensure the system is completely purged

of air and verify that system pressure is at least 12 psi on the pressure

gauge. If not, repeat the procedure.

d. The purge function can be accessed at any time by pressing ESC for

ve (5) seconds. Press ESC to exit.

A. First Ignition

1. Make sure that the gas valve is closed and the electrical connections

have been properly wired and grounded.

2. Ensure that the system pressure is at least 12 psi on the tridicator

and no hot water or heating requests will be made.

NOTE: It is recommended to ll and purge the entire system before

powering the boiler.

3. Power on the boiler (press the ON/OFF button).

4. The boiler air purge function starts

NOTE: It is recommended to run through the full initial purge cycle at

install. Do not cut the purge cycle short.

5. The exhaust vent piping for combustion products should be suitable

and free from any obstructions.

6. Any necessary ventilation inlets in the room should be open (power

vent installation).

7. Set the room thermostat to the highest setting to start the boiler

and test Lockout Error 501.

NOTE: The boiler will display a Lockout Error 501 after the 3rd

consecutive failed ignition attempt.

- The combustion fan will pre-purge for a short time before activating

the igniter.

- Ensure the combustion fan post-purges for at least 5 seconds before

reactivating the igniter.

- After the boiler displays Error 501, set the room thermostat to the

normal setting to start the boiler.

8. Open the gas valve and check the connection seals, including the

boiler connection seals. Check for and eliminate any leaks.

9. Press the RESET button to clear Error 501. The display will show OK.

10. Start the boiler by selecting CH or DHW operation.

11. Proceed with Combustion Checking Procedure.

FOR YOUR OWN SAFETY READ BEFORE OPERATING

1. This boiler does not have a pilot. It is equipped with an ignition

device which automatically lights the burner. Do not try to light

the burner by hand.

2. BEFORE OPERATING: Smell all around the boiler area for gas.

Be sure to smell next to the oor because some gas is heavier

than air and will settle on the oor.

3. WHAT TO DO IF YOU SMELL GAS

• Do not try to light any boiler.

• Do not touch any electric switch, do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas suppliers’ instructions.

• If you cannot reach your gas supplier, call the re

department.

• Turn off the gas shutoff valve (located outside the boiler) so

that the handle is crosswise to the gas pipe. If the handle

will not turn by hand, don’t try to force or repair it, call a

qualied service technician. Force or attempted repair may

result in a re or explosion.

4. Do not use this boiler if any part has been under water.

Immediately call a qualied service technician to inspect the

boiler and to replace any part of the control system and any gas

control that has been damaged.

5. The boiler shall be installed so the gas ignition system

components are protected from water (dripping, spraying, rain,

etc.) during boiler operation and service (circulator replacement,

condensate trap, control replacement, etc.)

Failure to follow these instructions could result in property

damage, serious personal injury, or death.

If you discover any evidence of a gas leak, shut down the boiler

at once. Find the leak source with a bubble test and repair

immediately. Do not start the boiler again until the leak is

repaired. Failure to comply could result in substantial property

damage, severe personal injury, or death.

WARNING

Part 11 - Start-Up

B. Combustion Checking Procedure

The order of operations for this procedure

must always be respected.

Operation 1 - Gas inlet pressure check

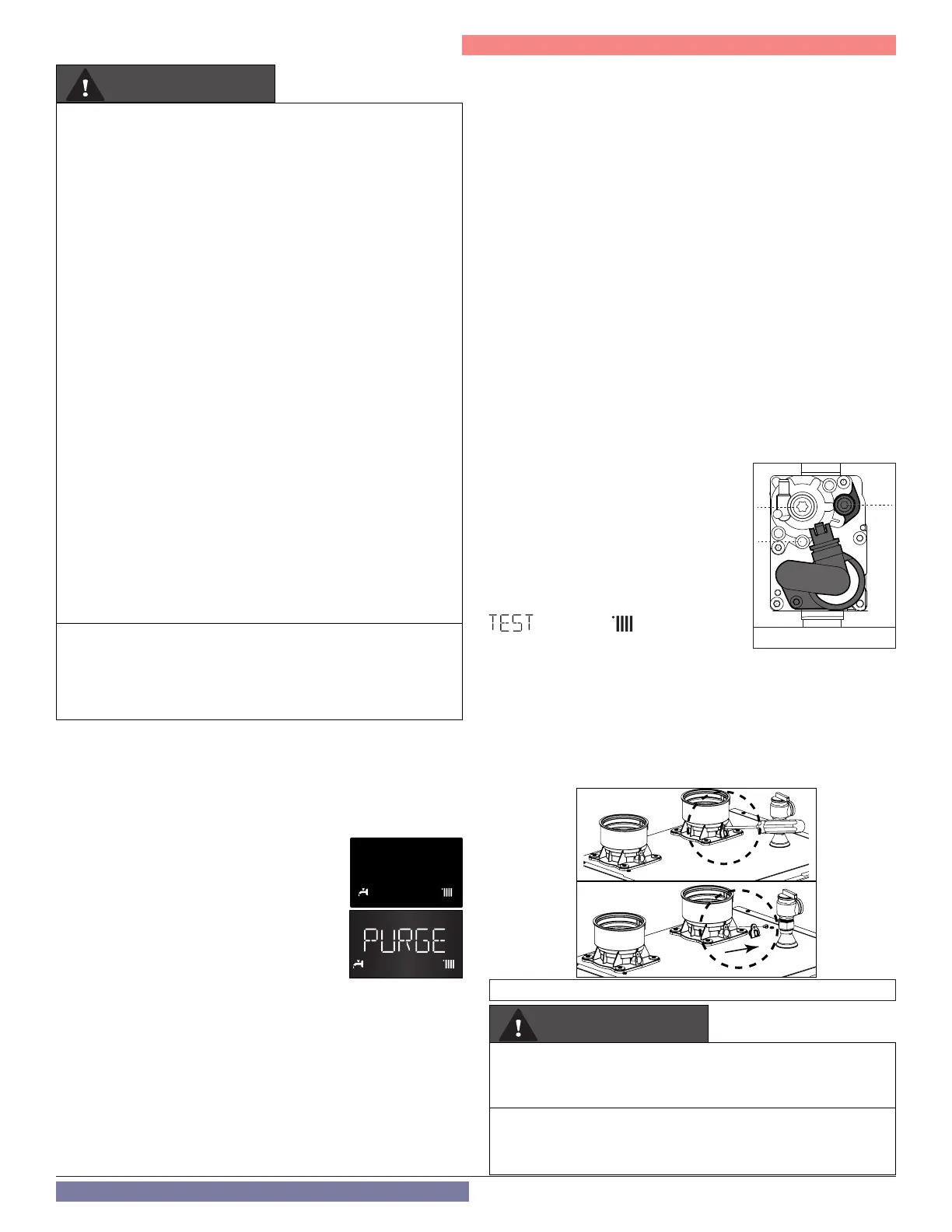

Loosen screw 1 (Torx 10 - Line Pressure Test

Port) and connect a manometer to the port

using applicable tubing.

Ensure the boiler is powered on. Then

enable Test Mode by pressing the RESET

button for 10 seconds. The display will show

and the icon .

The gas line pressure must remain within the

range provided in Table 21 for the gas type

during all operating conditions. Upon completion of the combustion

analysis and adjustment (Operations 2 through 5), remove the pressure

gauge and tighten screw 1. Verify and repair any gas leaks.

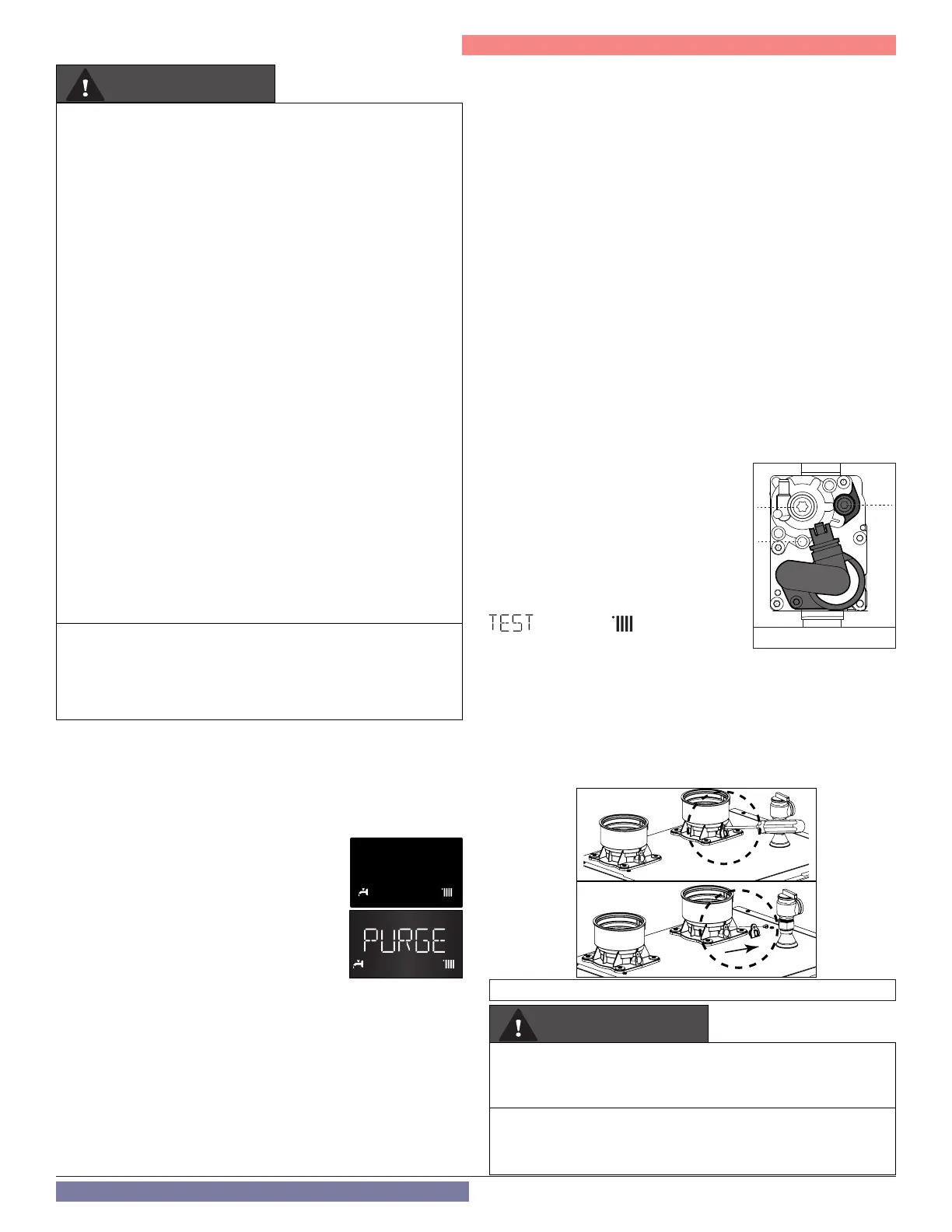

Operation 2 - Combustion Analysis

Remove the combustion test port plug as illustrated, and insert a

calibrated combustion analyzer.

4

2

1

Figure 73 - Gas Valve

Figure 74 - Combustion Test Port

Make sure the calibrated combustion analyzer is set to the

appropriate gas type. Failure to do so could result in serious

personal injury or death.

It is required to use a calibrated combustion analyzer to verify

nal adjustment according to the combustion chart (Table 30).

Failure to do so could result in serious personal injury or death.

WARNING

Loading...

Loading...