3. ENGINE

3-

NOTE: During disassembly, do not damage the

sealing surfaces of the crankcase halves.

Pull crankshaft out of crankcase.

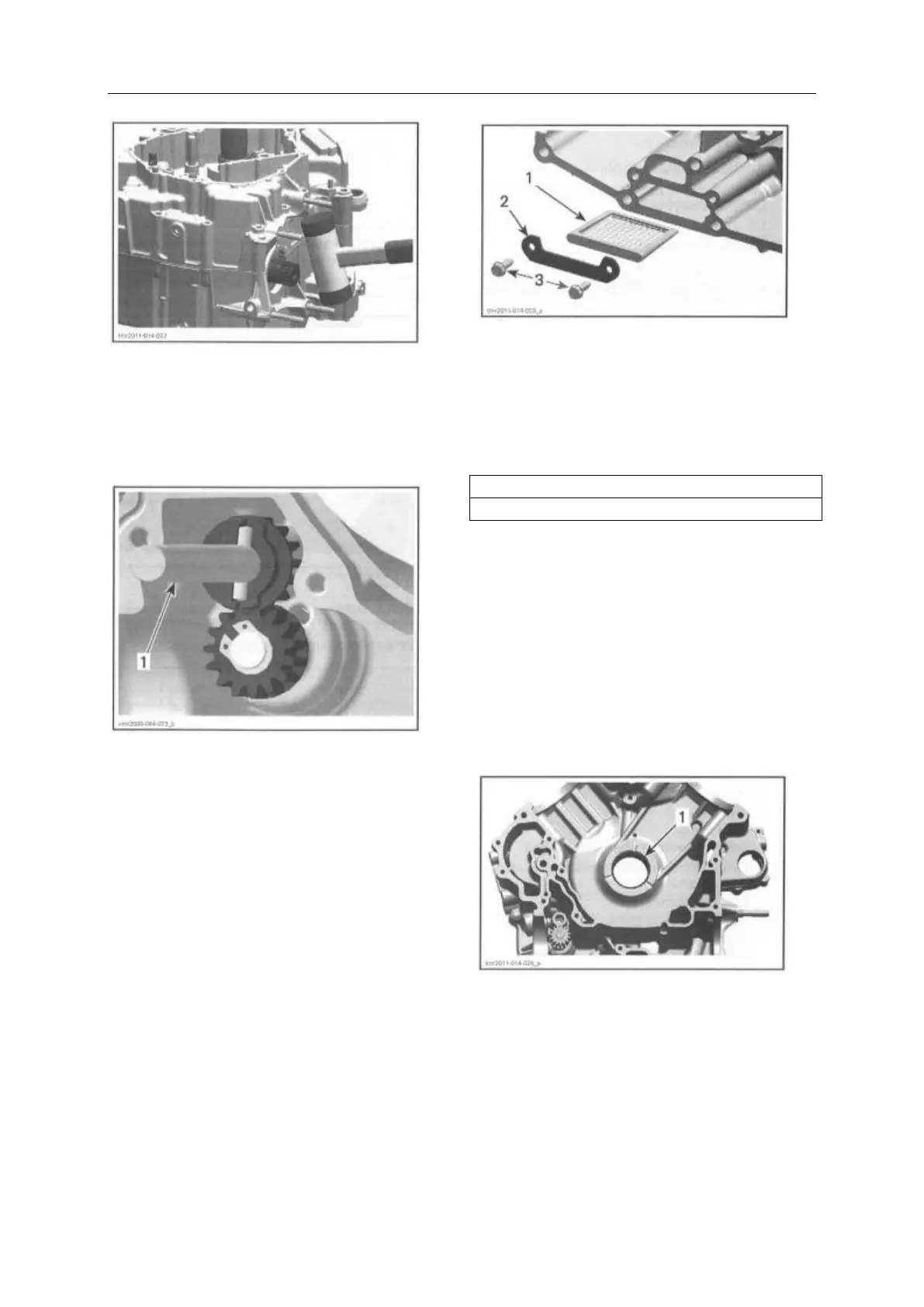

Remove the water pump intermediate shaft.

1. Water pump intermediate shaft

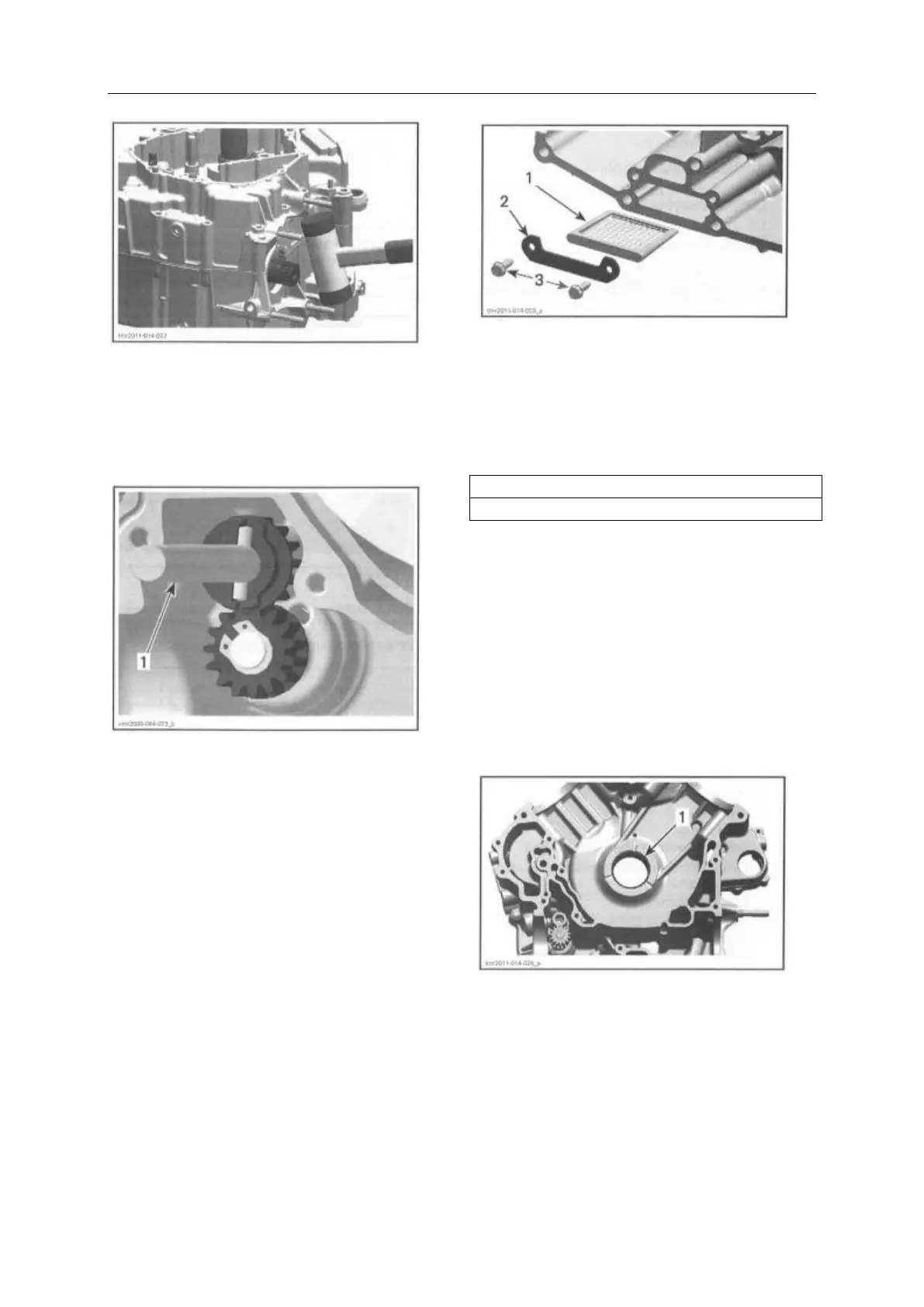

Remove engine oil strainer.

NOTE: Oil strainer removal for inspection and

cleaning is recommended. Refer to

LUBRICATION SYSTEM subsection.

1. Engine oil strainer

2. Retaining plate

3. Screws

Crankcase Cleaning

Use safety goggles to avoid eye injuries

Clean crankcase using a part cleaner.

Dry crankcase using compressed air .

Blow the oil supply lines.

Crankcase Inspection

Check crankcase halves for cracks or other dam-

age. Replace if damaged.

Check MAG and PTO plain bearings in for scoring

or other damages.

1. Plain bearing

NOTE: Measure plain bearing inside diameter and

compare to PT0/MAG main journa1 diameters of

crankshaft (refer to CRANKSHAFT). Replace if

the measurements are out of specification.

Loading...

Loading...