3. ENGINE

3-

TDCDIAL

INFICATOR

(P/N 414 104 700)

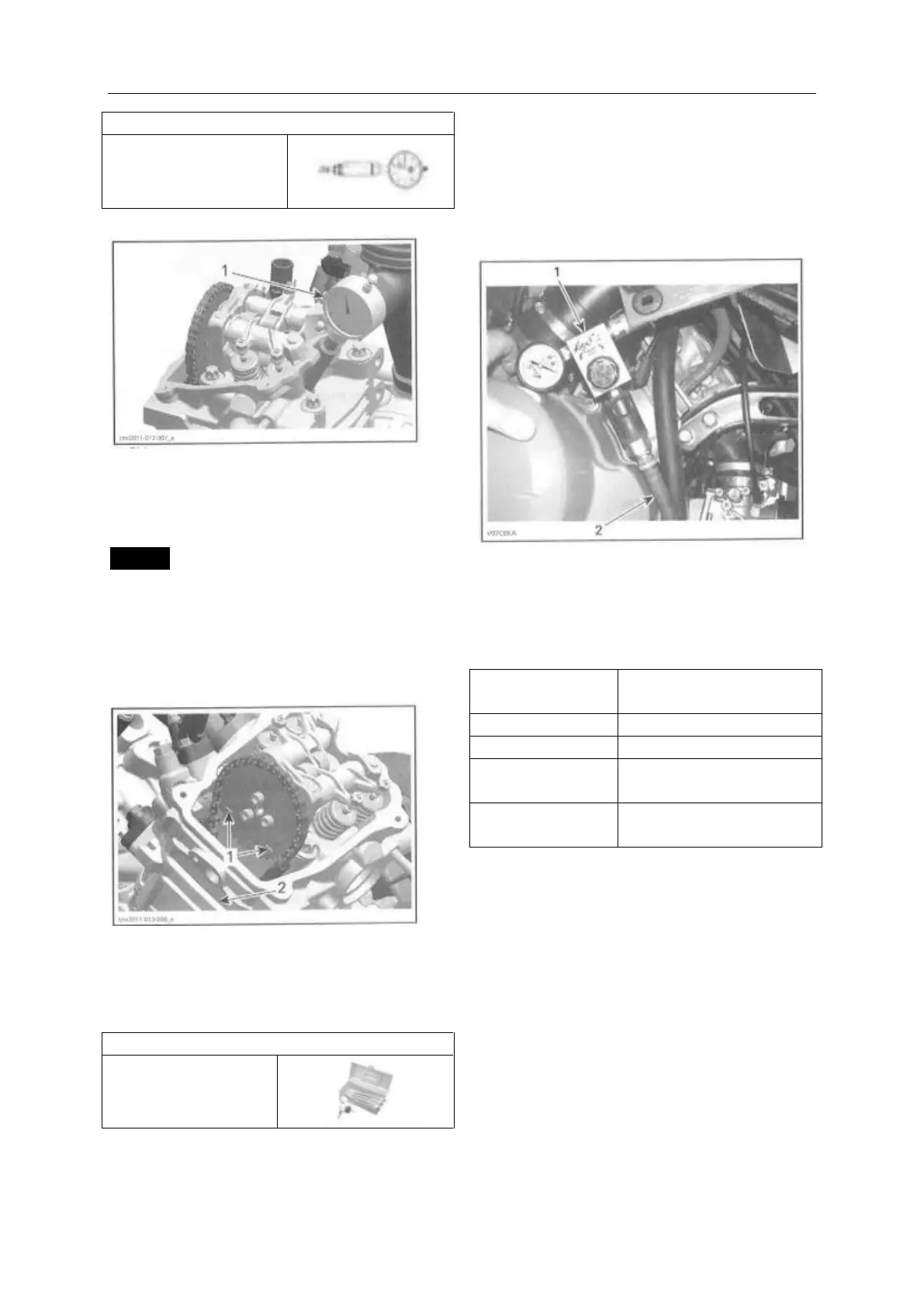

1. Dial gauge

NOTE: If a dial gauge is not available , use a

screw driver or another similarly suitable tool.

NOTICE Do not scratch or damage piston/

cylinder surface.

NOTE: At ignition TDC the marks on the camshaft

timing gear have to be parallel to cylinder head

base as per following illustration.

1. Marks on camshaft timing gear

2. Cylinder 1leaol base

Leak Test

ENGINE LEAK

DOWN TEST KIT

(P/N 529 035 661)

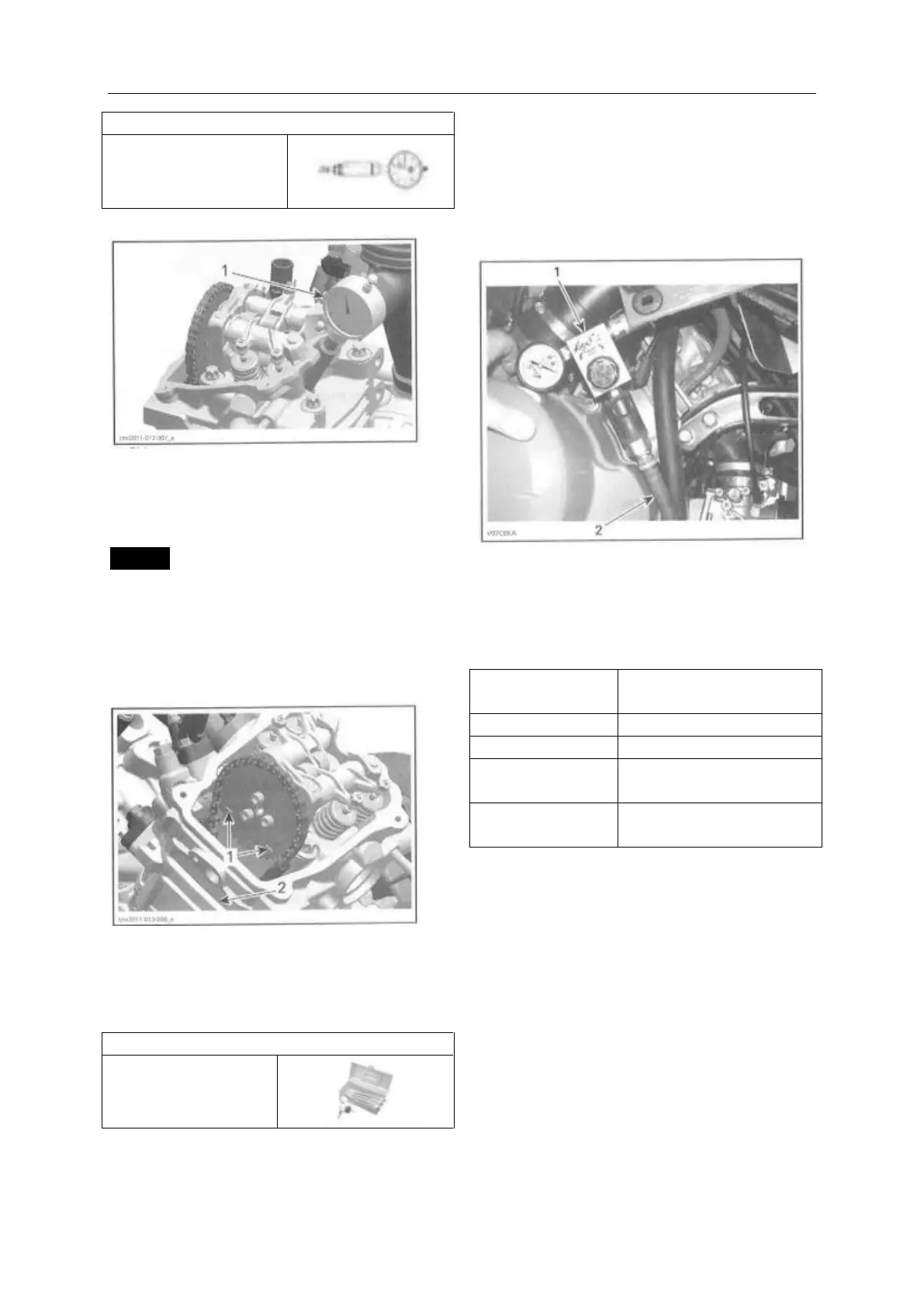

Connect leak tester to adequate air supply

Set needle of measuring gauge to zero.

NOTE: All testers have specific instructions on

gauge operation and required pressure.

Install gauge adapter into previously cleaned spark

plug hole.

Supply combustion chamber with air pressure.

TYPICAL

1. Leak tester

2. Air supply hose

Note the amount or percentage of leakage

(depending on tester).

Fair condition; reduced

engine performance

Poor condition , diagnose

and repair engine

NOTE: To make sure there is no false reading due

to a valves not perfectly seated, tap each valve

adjustment screw (on the rocker) using a soft

hammer.

Diagnosis

Listen for air leaks .

_ Air escaping in intake port/throttle body means

leaking intake valve(s).

_ Air escaping in exhaust port means leaking

exhaust valve(s).

_ Air bubbles in the coolant (radiator) means

leaking cylinder head gasket.

_ Air/coolant escaping from cylinder/head means

damaged gasket(s) and/or loosened screws.

Loading...

Loading...