17

O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

E-mail:info@omacpompe.com SitoWeb:www.omacpompe.com

Rev.4 del 01/2011 O.M.A.C. s.r.l.

Chap.1 - pag.

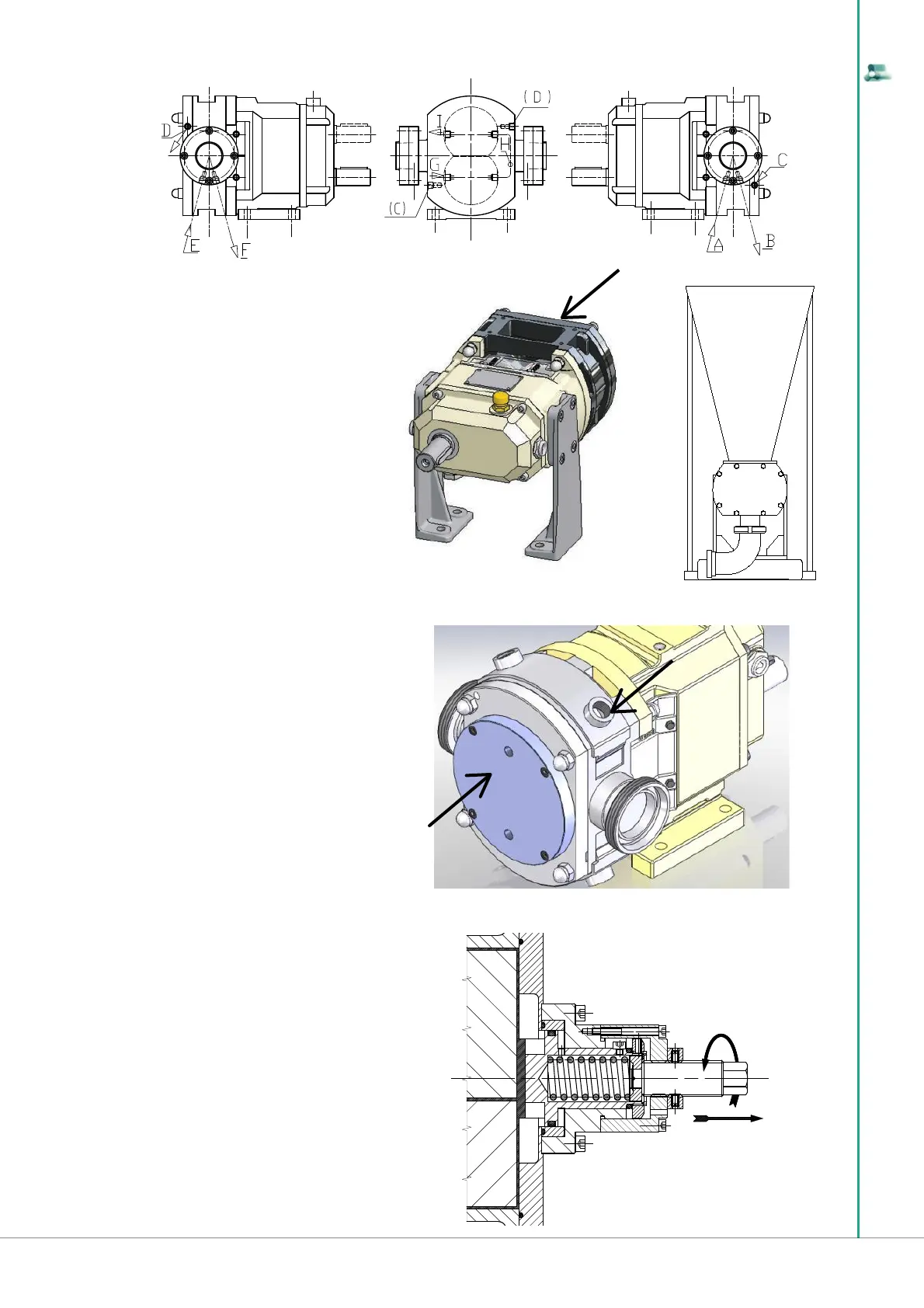

1.11.2 Pump with widened rectangular inlet port

1.11.3 Pump with heating/cooling chamber on pumping case and front cover

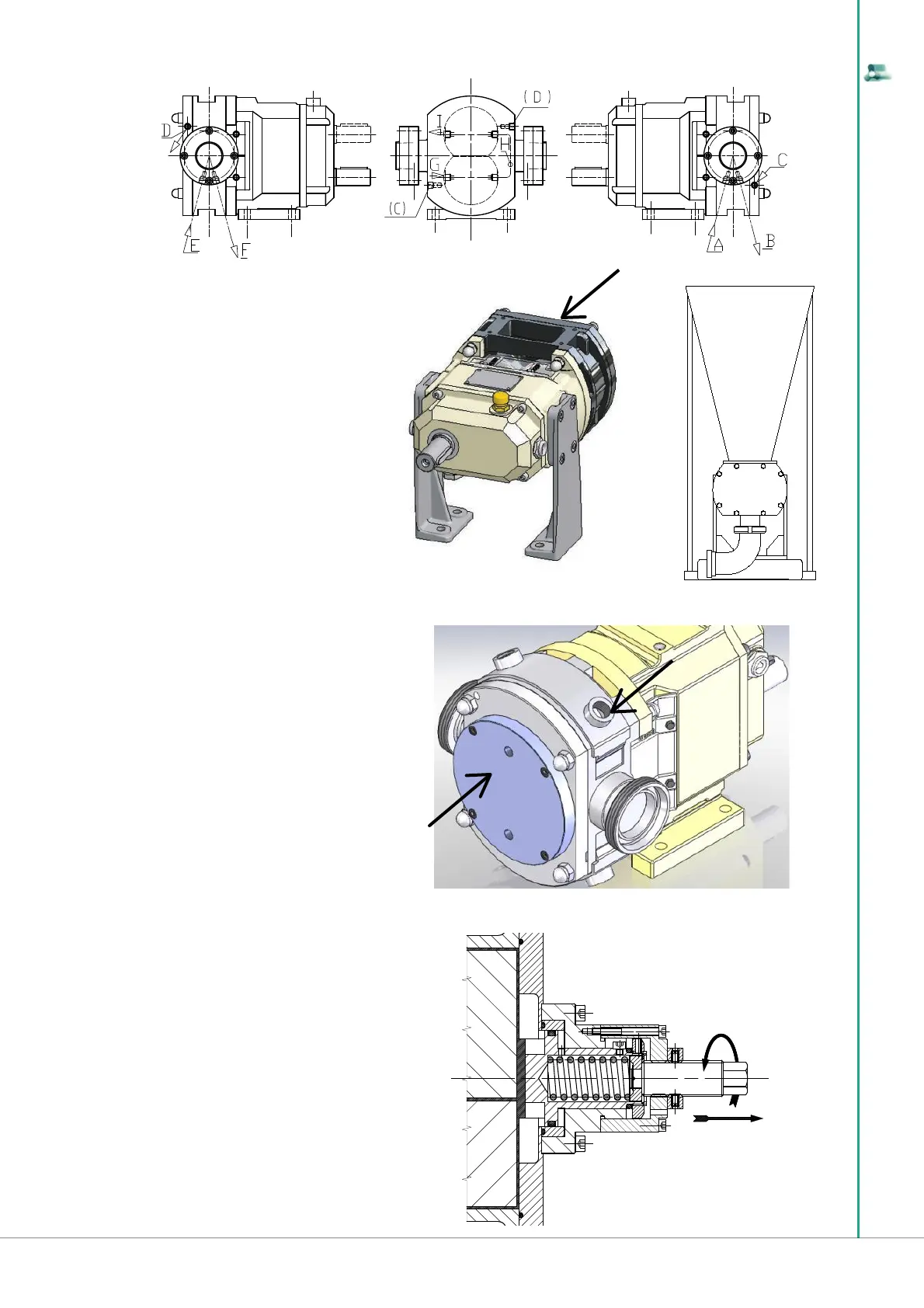

1.11.4 Pump with mechanical safety valve on front cover

Models B115, B220, B330,B390, B440, B490 can be

made with a rectangular widened suction inlet to facilitate

supply of the “B series lobe displacement pump” with very

viscous products such as mixtures or thick mixtures with

semi-solid pieces.

In these cases to facilitate the product to fall in, the pump

is installed with openings in vertical axis directly under the

hopper.

To connect the bare shaft pumps with vertical axis piping

one must disassemble the foot of the pump (fi xed for mo-

dels B100 - B550 - B6) and fi x the gear box directly to the

special feet that can be supplied upon request (already

included in the “vertical base”). If the “B series lobe displa-

cement pump” is supplied bare shaft (without control unit),

check the proper position of the caps and oil level.

In the event one wishes to maintain the pumped fl uid at a

constant temperature one can apply a cavity on the pump

body and/or cover for heating / cooling liquid circulation

to all the pumps of the range (excluding B100). Typical

cases are the transfer of glucose, chocolate, melted fats,

butter, margarine, and others.

For the dimensions of holes and the circuit diagram, con-

sult the table in section 1.3.9.

The pipes and couplings for the circuit are not supplied

with the pump.

One of the possible versions of the “B series lobe displa-

cement pump” envisions the possibility to fi t a mechanical

safety valve

on the front cover, which intercepts and dampens any

pressure peaks over the limit for which the valve is set.

• The safety valve, fi tted directly on the front co-

ver of the pump, is reversible and activated by a spring

compressed by a regulator;

• The setting of the safety valve must be car-

ried out on site by the Customer, because the entity of

the recycling depends on the pump speed, on the specifi c

weight and product viscosity.

• To prevent continuous vibrations, the safety

valve must be adjusted in such a way that it starts working

at a pressure 10% higher than the working pressure.

Loading...

Loading...