O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

Rev.4 del 01/2011 O.M.A.C. s.r.l.

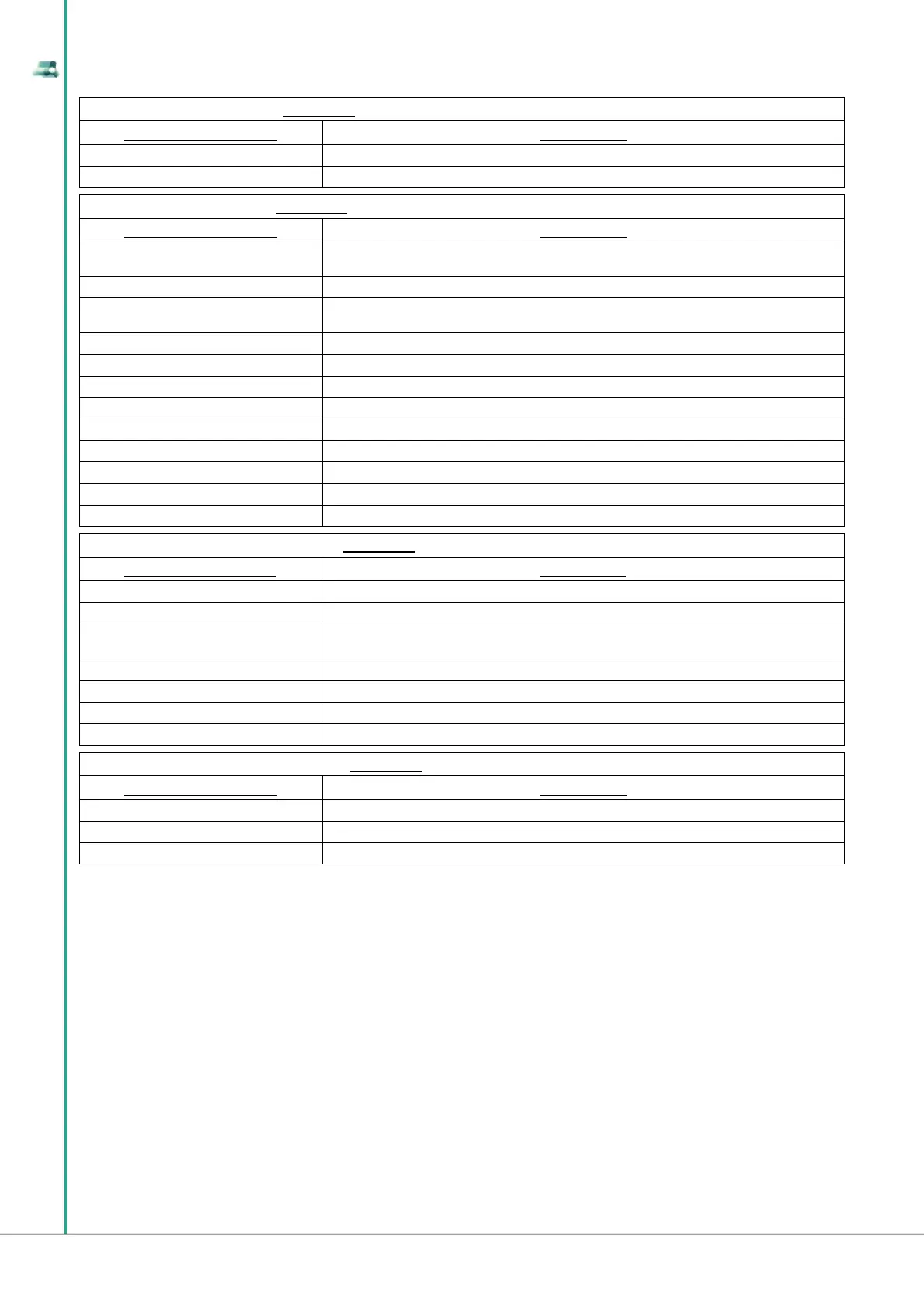

FAILURE: OVERHEATING OF THE PUMP (follow)

POSSIBLE CAUSES: REMEDIES:

Parts in contact in the pumping case Check the design pressure coincides with the operating pressure

The relief valve leaks Check the relief valve setting, clean sealing parts, substitute worn parts

FAILURE: OVERHEATING OF THE MOTORIZATION

POSSIBLE CAUSES: REMEDIES:

Low medium temperature Increase the temperature of the medium, heat the pumping case (within the limits given by the manufacturer)

Excessive medium viscosity Decrease the speed of the pump, increase the temperature of the medium

Excessive back-pressure

Remove possible obstructions in the outlet piping, increase the piping diameter, reduce its lenght and the number of the

bends

Too tight packing gland Loosen the packing gland and tighten it rightly (see instructions)

Excessive pump speed Decrease the speed of the pump

Piping press on pumping case Check the piping alignement, if necessary fi t fl exible expansion joints, and fi x the piping on the plant structure

Not aligned joint Check the alignement between pump and drive device

Worn out bearings Replace the bearings by the manufacturer

Worn out or untimed gears Replace the gears or time them according to the instructions

Wrong quantity / quality of gears oil Act according to the manufacturer’s instructions

Parts in contact in the pumping case Check the design pressure coincides with the operating pressure

Worn out rotors Replace rotors

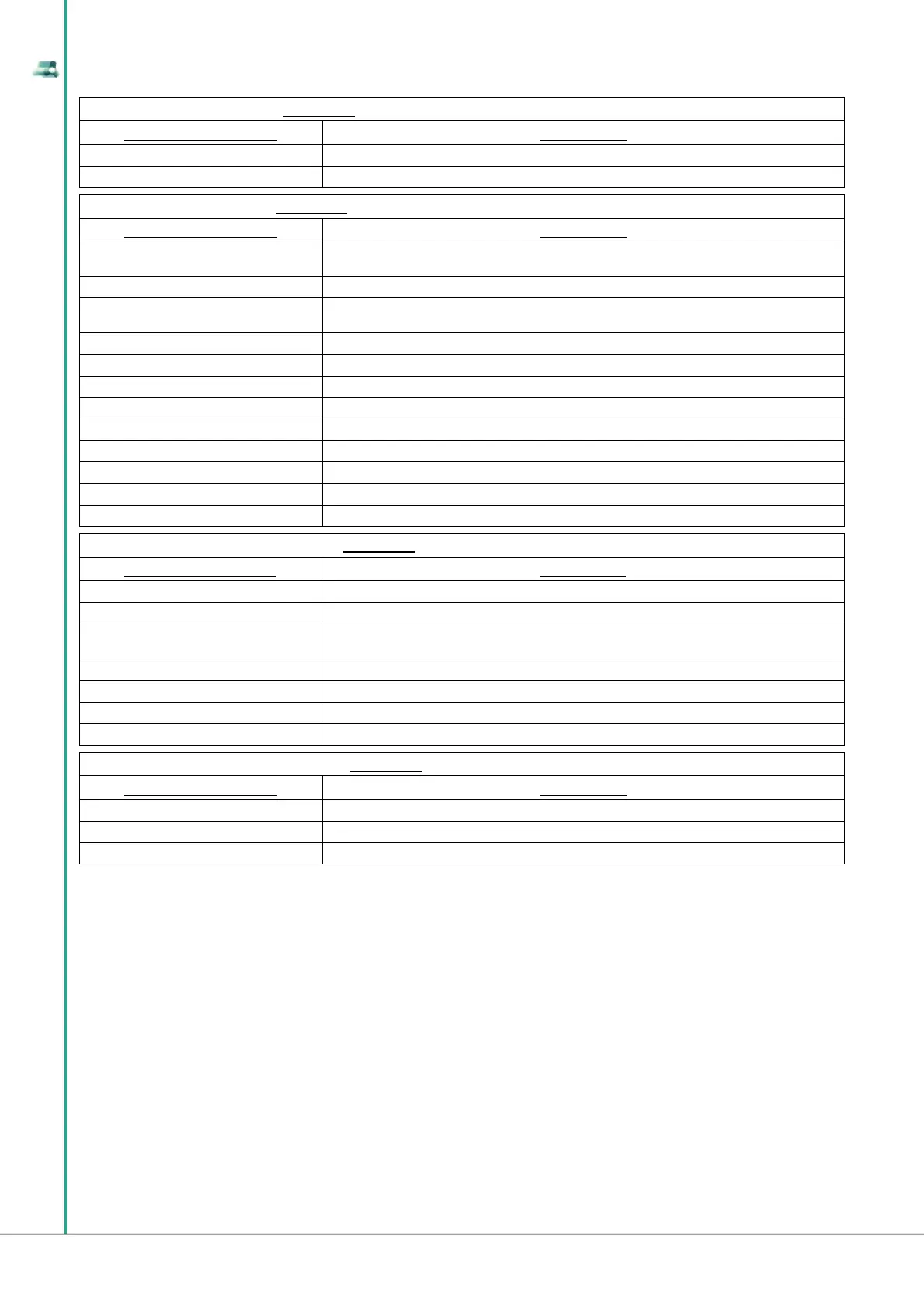

FAILURE: FAST ROTORS WEAR

POSSIBLE CAUSES: REMEDIES:

Excessive medium temperature Decrease the temperature of the medium, cool the pumping case

Presence of suspended particles in the medium

Clean suction piping and install a fi lter on it

Excessive back-pressure

Remove possible obstructions in the outlet piping, increase the piping diameter, reduce its lenght and the number of the

bends

Piping press on pumping case Check the piping alignement, if necessary fi t fl exible expansion joints, and fi x the piping on the plant structure

Worn out bearings Replace the bearings by the manufacturer

Worn out or untimed gears Replace the gears or time them according to the instructions

Parts in contact in the pumping case Check the design pressure coincides with the operating pressure

FAILURE: FAST SEALS WEAR

POSSIBLE CAUSES: REMEDIES:

Presence of suspended particles in the medium

Clean suction piping and install a fi lter on it

Too tight packing gland Loosen the packing gland and tighten it rightly (see instructions)

Insuffi cient fl ushing seal liquid level Check the fl ushing seal liquid and, if necessary, increase its fl ow-rate

5.2 Instruction for carrying out checks

Before any maintenance intervention one must provide all the security measures that comply with the accident prevention regulations in force. In parti-

cular inhibit operation of all electric utilities and discharge any residual energy.

The instruments and tools needed for good maintenance are those normally supplied as standard to a technician with assembly/maintenance tasks.

In the case the machine is positioned above ground level it is up to the Customer to make the machine accessible to the operator in order to permit

adjustment, maintenance, repair, etc. operations possible, in safety conditions.

In the case the process fl uid is subject to easy drying, crystallisation or sedimentation, it is essential to wash the pump and pipes at the end

of each operation, i.e. at the beginning of extended machine down time.

The reversibility of the rotation direction, common feature of all OMAC pumps, offers the possibility to recall the process fl uid, completely

emptying the delivery pipes and putting the product in storage.

If the LDPU is not use for a long period of time, when starting check that the sealing parts are not blocked by turning the pump shaft

manually.

If the process fl uid is subject to freezing or solidifi cation, ensure before starting, that the pipes and the pump body are not obstructed by solid

parts of fl uid, formed during inactivity.

The references below, with position number, are to intended as the exploded view drawing of the B series lobe displacement pump indicated

in section 1.3.

•

•

•

•

•

Loading...

Loading...