9

O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

E-mail:info@omacpompe.com SitoWeb:www.omacpompe.com

Rev.4 del 01/2011 O.M.A.C. s.r.l.

Chap.5 - pag.

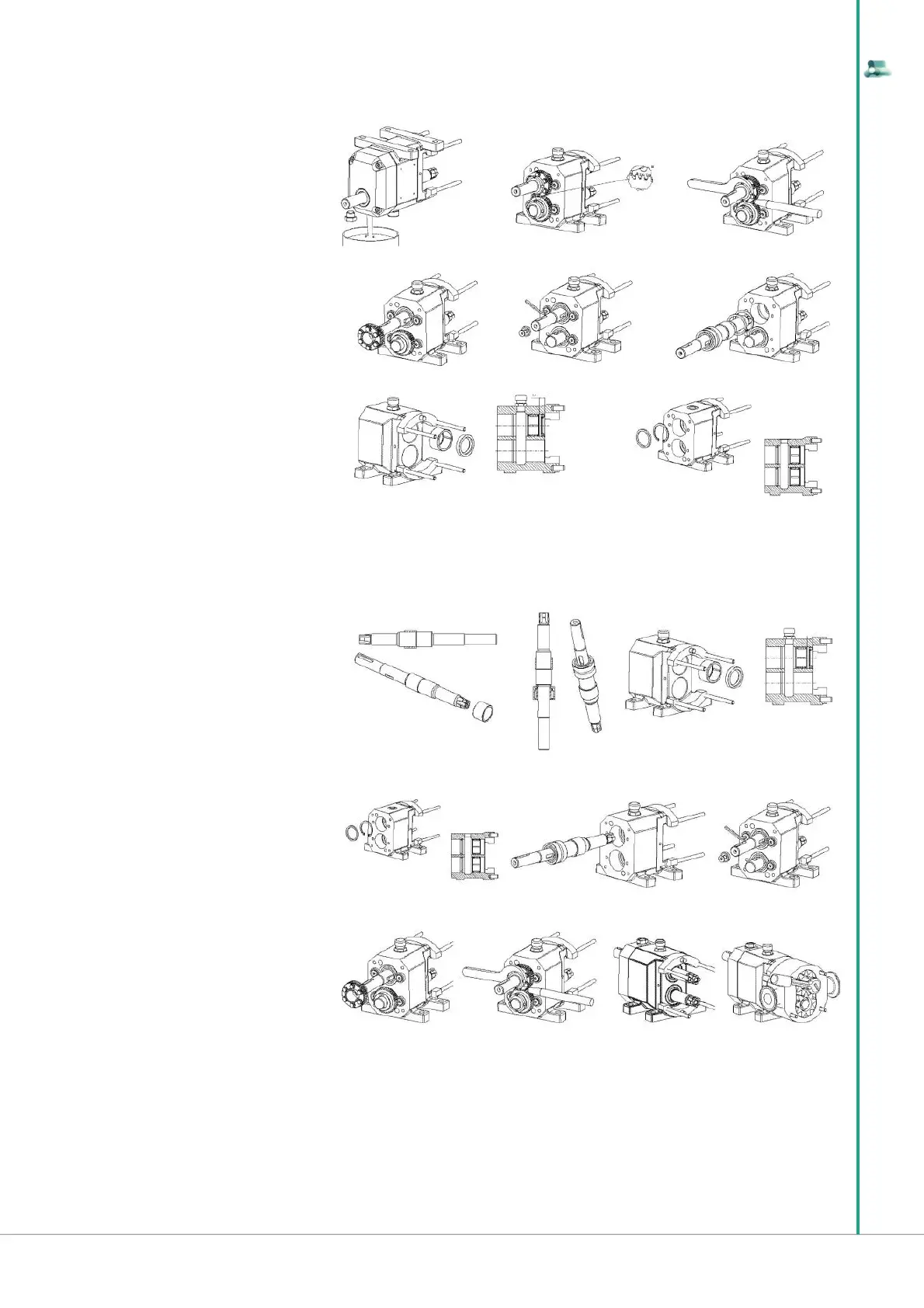

5.7.3 DISASSEMBLY OF THE BEARINGS BOX

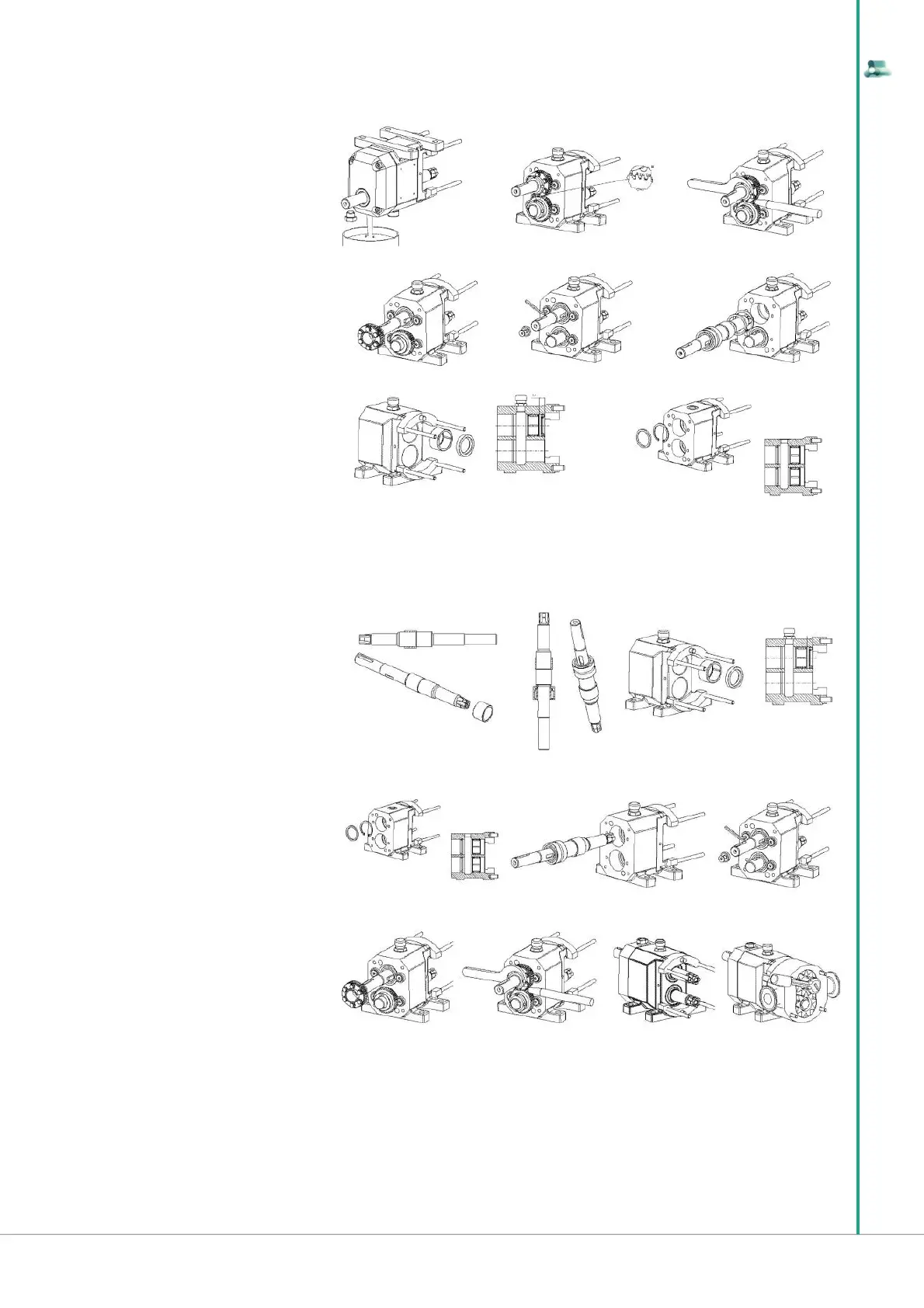

5.7.4 Assembly of the bearing box

15 After disassembling the rotor case, drain the

oil and the remove drive key on shaft

16 Remove the gear cover and make a refe-

rence mark on gears in order to respect the right

timing while reassembling

17 Disconnect the retainer keys on lock

washers

18 Unscrew the gear ring nut, inserting a non

metal wedge between gears in order to stop

turning

19 Disassemble the shafts, unscrewing the fl

athead screw, with the lock washer

20 Extract the shafts by the posterior side of

the pump

21 extract the oil retainer and the external rings

of the front bearing

22 extraxt the spacers and the snap rings

23 *BEARING ASSEMBLING PHASE*

Prepare the shafts and the bearings, checking

they are without dents and burrs

24 Drive the inner ring on the driving shaft. Re-

peat the operation on the drived shaft

25 Assemble the rear bearing on the driving

shaft and then on the drived one

26 Drive the external bearing rings on the gear

box, observing the depth on the fi gure (10 mm)

27 Insert the snap rings and the spacers for

the axial setting

28 Assemble the shafts by the rear side of the

pump, respecting the timing previously marked

while reassembling, with the numbers marked

“1” and “2” turned towards the high

30 The gear couple is composed by a fi xed gear and an adjustable one. Assemble the fi xed gear, then the adjustable one with untightened screws,

taking care to a fi rst approximate rotor timing

29 Fixed the rear bearings with the washers

and the fl athead screws

31 Tighten the retainer ring nuts with the corresponding safety washers and set rightly the suited retainer key. In order to avoid turning during operation

insert a wedge in soft material among the gear teeth

33 Being the wedge inserted among the gears tighten the rotor nuts, taking care of the driving torque (see par.1.3.6)

32 Assemble the rotor case and rotors as previously described and check the “Clearences” (see par.1.3.4).

If rotor clearances are not included in tolerances as prescribed in chap. 1, disassemble rotors, the rotor case and adjust the spacer according to the

requested dimension

15

16 17

18

19

20

21

22

23+24 25 26

27 28 29

30 31 32 33

Loading...

Loading...