O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

Rev.4 del 01/2011 O.M.A.C. s.r.l.

Never carry out any type of maintenance intervention directly, always contact the maintenance manager. Only this person is qualifi ed to carry out main-

tenance operations professionally and in safety conditions. Before carrying out maintenance activities on the LDPU, ensure that there are no danger

situations and that the machine and plant it is connected to are in emergency stop conditions.

1.8 Noise and vibrations emitted

In the envisioned conditions and methods, the sound level test was carried out to defi ne the noise value emitted by the LDPU. The sound level test of the

LDPU was performed using water as process fl uid, and using the O.M.A.C. pumps testing plant.

The sound level values detected were determined applying standard EN12639 and adopting the measuring specifi cations of ISO 3746, and are the

following:

Sound power level equivalent to 2 meters distance in work: 65 dB(A).

1.9 Use of the personal protection equipment

During the LDPU assembly and disassembly operations, as during its routine and extraordinary maintenance, one must wear the personal protection

equipment, according to the operation and risk connected to the activity performed by the appointed operator.

DANGER

It is absolutely forbidden to perform maintenance or repairs interventions on the LDPU, without having worn the PPE.

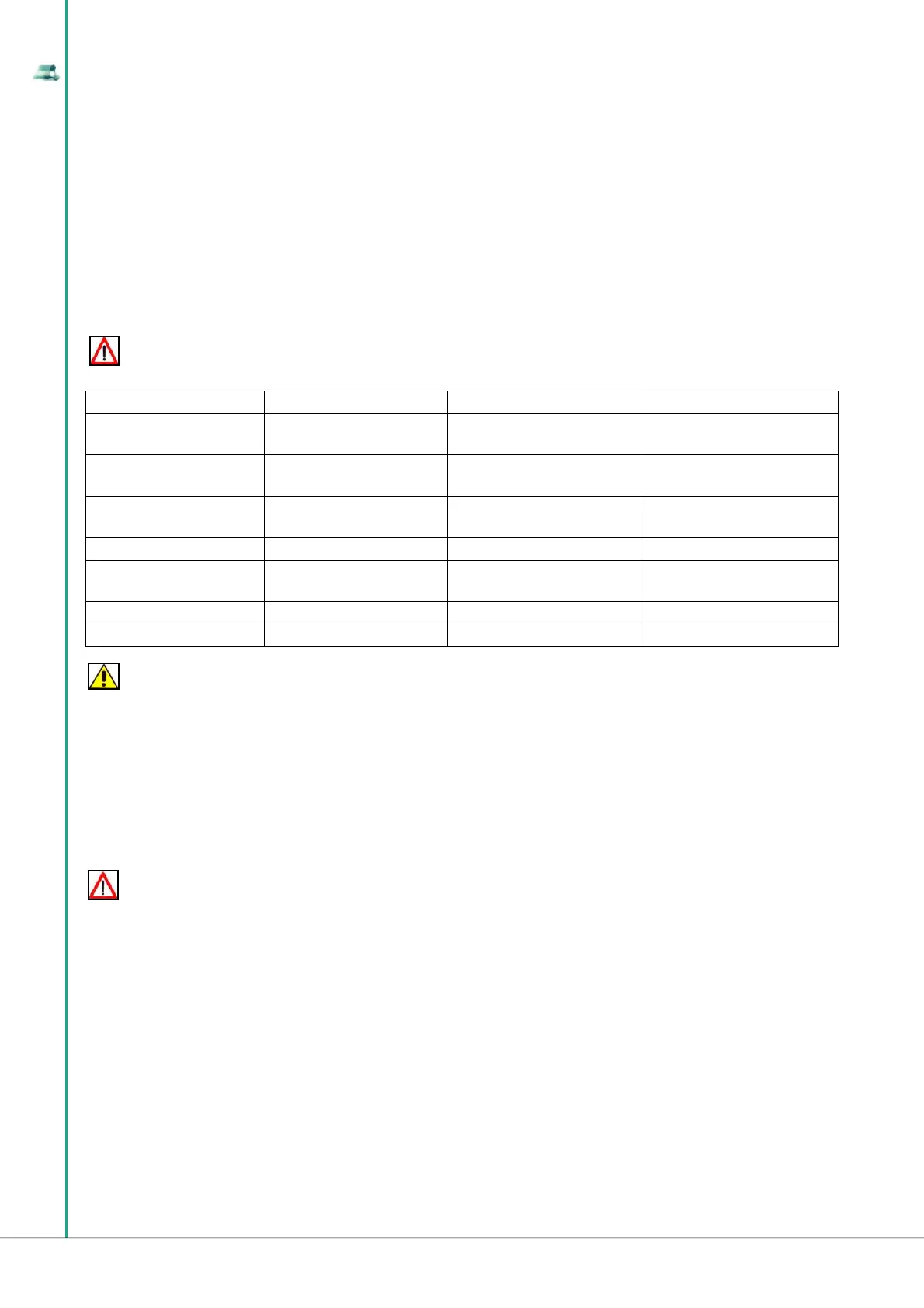

PPE RISK USE EXPOSED PERSONNEL

Shoes with reinforced toe

caps and non-slip soles

Lower limbs crushing always maintenance operator / operator

Coated safety gloves cuts and abrasions to upper limbs during installation or use of the unit maintenance operator / operator

Safety goggles Dust during installation or use of the unit maintenance operator / operator

Filtering face mask exposure to chemical agents maintenance or cleaning maintenance operator

Neoprene safety gloves exposure to chemical agents maintenance or cleaning maintenance operator

Work clothes Dust, entangling always maintenance operator / operator

Ear plugs Noise use of the pump unit operator

ATTENTION

To prevent mechanical risks, such as dragging, entrapment and other, do not wear accessories such as bracelets, watches, wings or chains.

1.10 Personnel training

The LDPU is made in such a manner to enable use directly by qualifi ed personnel, for this reason one does not envision training periods, however the

user, before performing any activities, must:

• carefully read this use and maintenance manual, paying attention to chapter 4, “Use of the machine”,

• supervise routine maintenance operations;

• supervise the proper use of the LDPU;

• check the protection devices work.

DANGER

Children, disabled persons, persons with by-passes or cardiac problems are not admitted as operators.

Therefore it is up to the customer to train the personnel appointed to use the machine, before it is commissioned.

The operator must have a technical professional qualifi cation, as well as suitable knowledge of general safety standards.

During the training course, the training level of the operator must be supervised by the customer company, which has the technical and organisational

knowledge necessary to carry out such task.

As provided by the current regulatory framework on health and safety at work, the training process should be formalised directly by the customer.

1.11 B Series lobe positive displacement pump optional features

1.11.1 Pump in aseptic version

Excluding models B100, B660, B680, one can make the “B series lobe displacement pump” , part of the machine, in aseptic version (with steam or sterile

liquid barrier on the cover), on the mechanical seals and openings. The aseptic LDPU is used in transfer processes of alimentary or chemical fl uids which

have undergone sterilisation and must not be contaminated in any way during transfer.

In the fi gures below there are the indications of inlet holes (A, C, E) and outlet holes (B, D, F) of the sterile liquid or steam inside the openings (A, B, E,

F) of the pumping body and the cover of the pump body (C, D). For the seals consult section 1.3.9.

•

Loading...

Loading...