O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

Rev.4 del 01/2011 O.M.A.C. s.r.l.

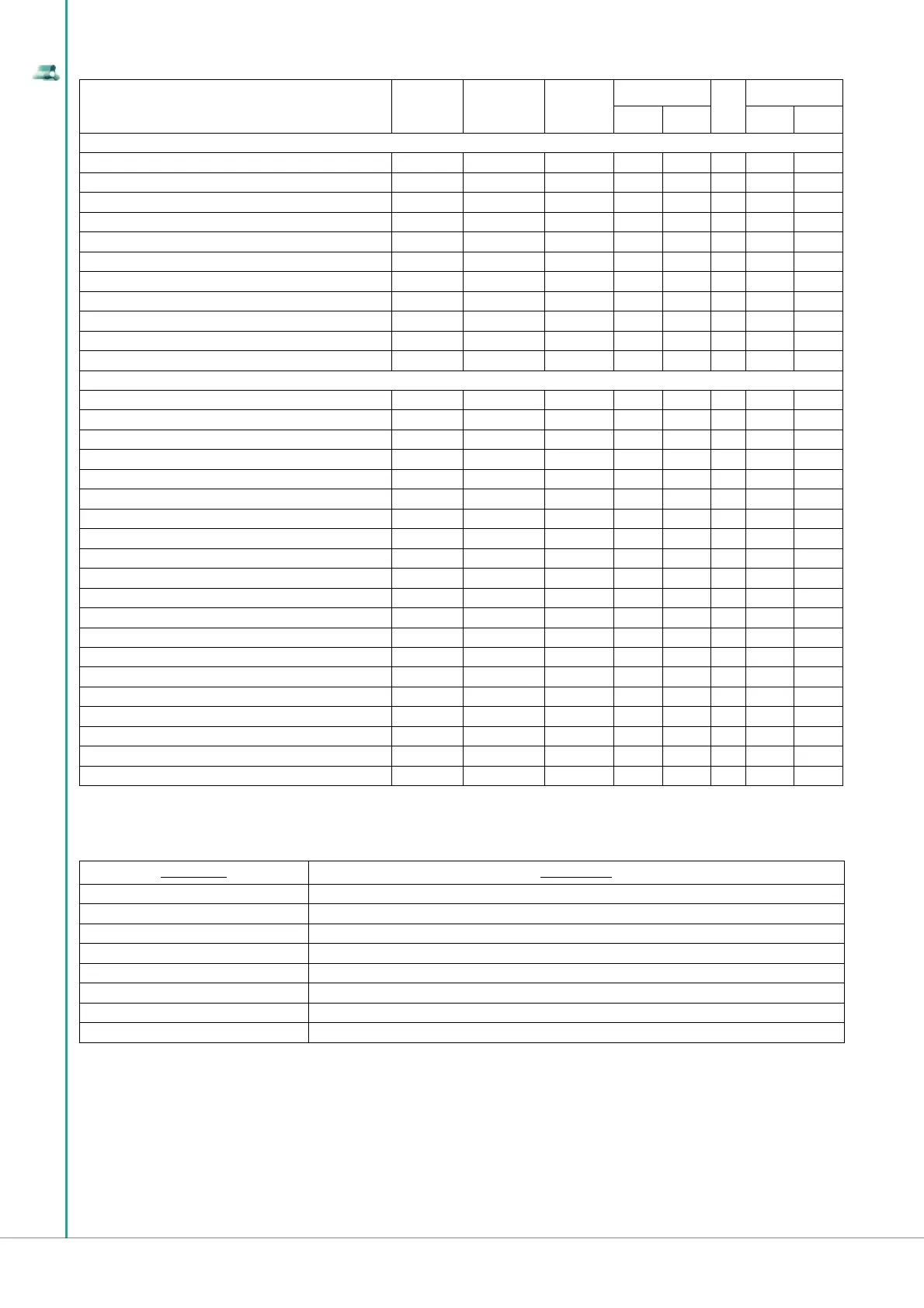

PRODUCTS

VISCOSITY

cPs

TEMPERATURE

°C

SPEED

RPM

SEALS

O-RING

ROTORS

1° 2° 1° 2°

COSMETICS AND PHARMACEUTICAL PRODUCTS

DODECILBENZENSULPHONIC ACID 6000 18 300-400 5 - V 0 -

DETERGENTS 100-4000 18 250-400 5 3 V 0 -

HAND CREAM 800-35000 20 150-350 5 3 V 0 -

SHAMPOO 2000 20 250-350 5 3 T 0 -

HAIR GEL 5000 20 250-350 5 3 T 0 -

NAIL POLISH 10000 20 250-350 5 - P 0 -

SOAP 3000 20 150-250 1 - V 0 -

TOOHPASTE 100000 18 50-150 5 1 V 0 -

HYDEROGEN PEROXIDE 1 15 300-400 7 5 V 0 -

GLYCERINE 600 18 250-350 6 4 T 0 -

VASELINE 30000-500 10-40 40-350 5 - T 0 -

INDUSTRIAL PRODUCTS

CITRIC ACID 1 20 300-450 3 - T 0 -

SULPHONIC ACID 125 30 250-400 5 6 V 0 -

NEUTRALIZED ETHOXYL ALCOHOLS 200-600 60-30 300-400 5 - P 0 -

ISOPROPYL ALCOHOL 1 20 300-400 3 - U 0 -

FLAVOUR FOR TOBACCO 10-100 20 300-450 5 3 T 0 -

FERMENTATION SOUP 20 20 250-350 3 - T 0 -

CELLULOSE 6000-15000 18 250-350 5C - P 0 -

WAX 500 93 200-300 5 - T 0 -

VINYL GLUE 1500 18 200-300 5C 1 V 0 -

UREIC PHENOLIC GLUE 600 20 200-300 5C 1 P 0 -

LATEX EMULSION 200 20 300-400 5C - P 0 -

PARAFFIN EMULSION 3000 18 250-350 5 - V 0 -

ETHYLENE 20 20 250-400 3 - T 0 -

ETHYLENE GLYCOL 10 20 250-400 3 - T 0 -

PRINTING INK 500-2000 35 300-500 6 - V 0 -

FLUID SILICONS 500 40 300-400 5C - P 0 -

DYES 1-200 20 300-500 6 - V 0 -

ACRYLIC RESIN 5000 20 200-300 5C 1 P 0 -

ALKYL RESIN 180-900 5-40 250-350 5C 1 V 0 -

VINYL RESIN 5500 20 200-300 5C 1 V 0 -

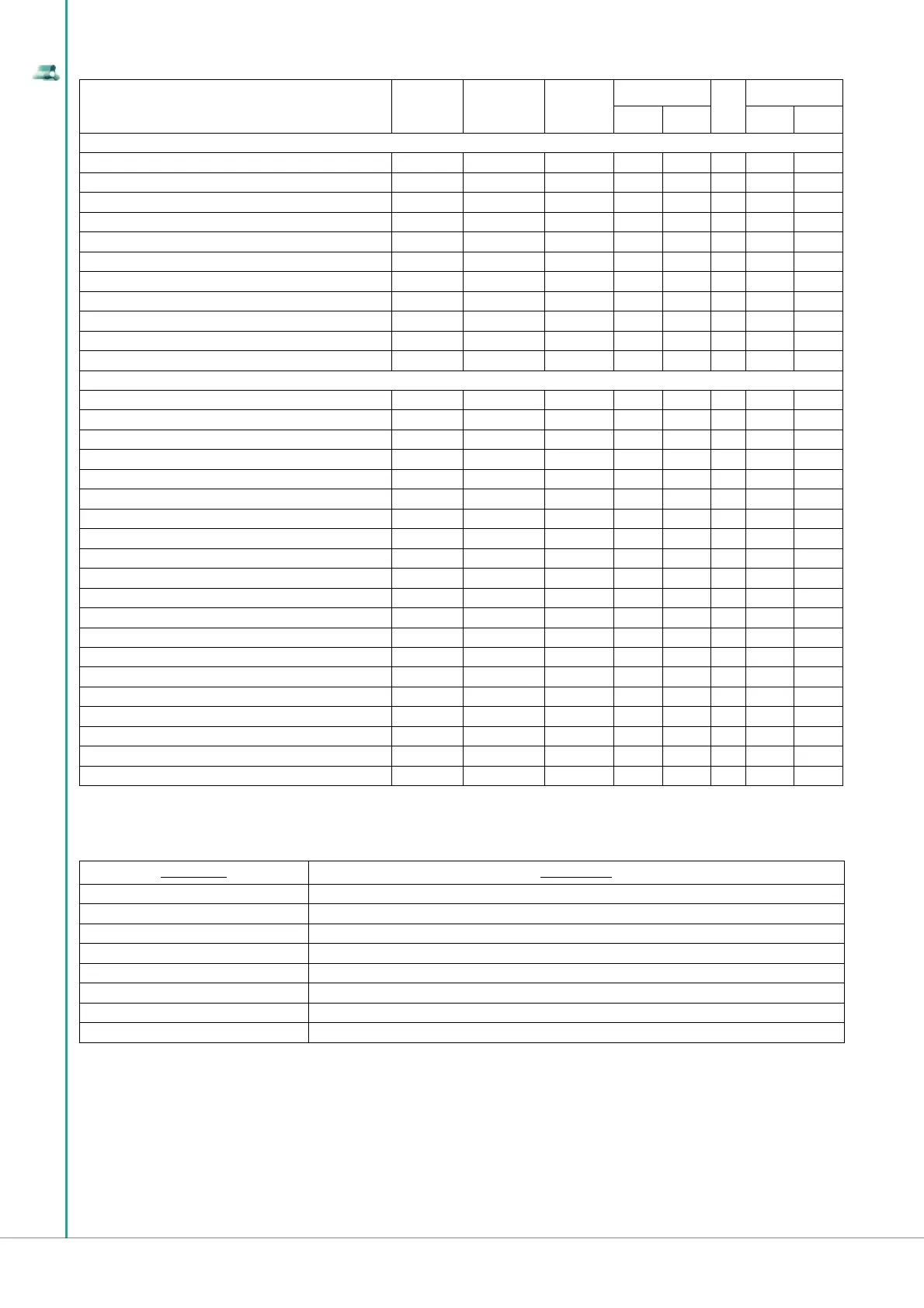

1.5 Material specifi cations

Below, listed per each component (bearings box, rear cover, pumping body,..) of the B Series lobe displacement pump, inserted in the LDPU, are the

materials the components can be made of.

COMPONENT USED MATERIALS

BEARING HOUSING CAST IRON GG25

GEAR COVER B1 B2 B3 B4 SERIES ALLOY

GEAR COVER B5 B6 SERIES CAST IRON GG25

PUMPING CASE AISI 316 L or in optional: HASTELLOY C276; TITANIO GRADO 5; DUPLEX SAF 2507

SHAFTS AISI 316 L or in optional: HASTELLOY C276; TITANIO GRADO 5; DUPLEX SAF 2507

ROTORS WITH STANDARD CLEARANCES AISI 316 L or in optional: HASTELLOY C276; TITANIO GRADO 5; lega antifrizione CY5SnBIM

ROTORS WITH INCREASED CLEARANCES AISI 316 L or in optional: HASTELLOY C276; TITANIO GRADO 5; lega antifrizione CY5SnBIM

RUBBER COATED ROTORS Anima in AISI 316 L + optional one of the following elastomers: N.B.R., E.P.D.M., °VITON (F.K.M.)

1.6 Occupied workplaces

The LDPU does not occupy any operator in a fi xed manner. The operator occupies an occasional workplace and checks its proper operation as per the

inspection and checking activity of the productive line the LDPU is part of.

1.7 Indication of the safety systems

In order to reduce the risks associated with malfunctions or misuse, the LDPU is equipped with the following security systems that are able to prevent /

manage situations of danger for the operator:

fi x ed joint transmission guards;

emergency stop button;

seal protections (excluding the LDPU version with fl ushed mechanical seals or double mechanical seals).

•

•

•

Loading...

Loading...