3

O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

E-mail:info@omacpompe.com SitoWeb:www.omacpompe.com

Rev.4 del 01/2011 O.M.A.C. s.r.l.

Chap.3 - pag.

STAGE 1: PLACEMENT

Following the provisions of section 3.3.1 - Preliminary checks - and on the basis of the indications of chapter 2 of this use and maintenance manual, the

operators must see to harness and handle the LDPU to place it in the position required by the Customer and specifi ed in the plant layout.

During this stage, one will need to use a forklift with suitable capacity, driven by personnel appointed by the Customer, as per chapter 2. One must pay

utmost attention in placing the LDPU in the envisioned position without intervening on the unit piping.

In the LDPU version with adjustable feet, the operators will see to measuring the height of the suction and delivery piping of the unit, after having positio-

ned the machine. Then they must adjust the height of the unit openings at the measured height, acting on the adjustable feet. Once the second operation

is complete, they can free the unit from the harnesses and proceed with stage 2 - fi x ing and installation, hooking the openings of the unit pumping part

by screwing them onto the plant piping.

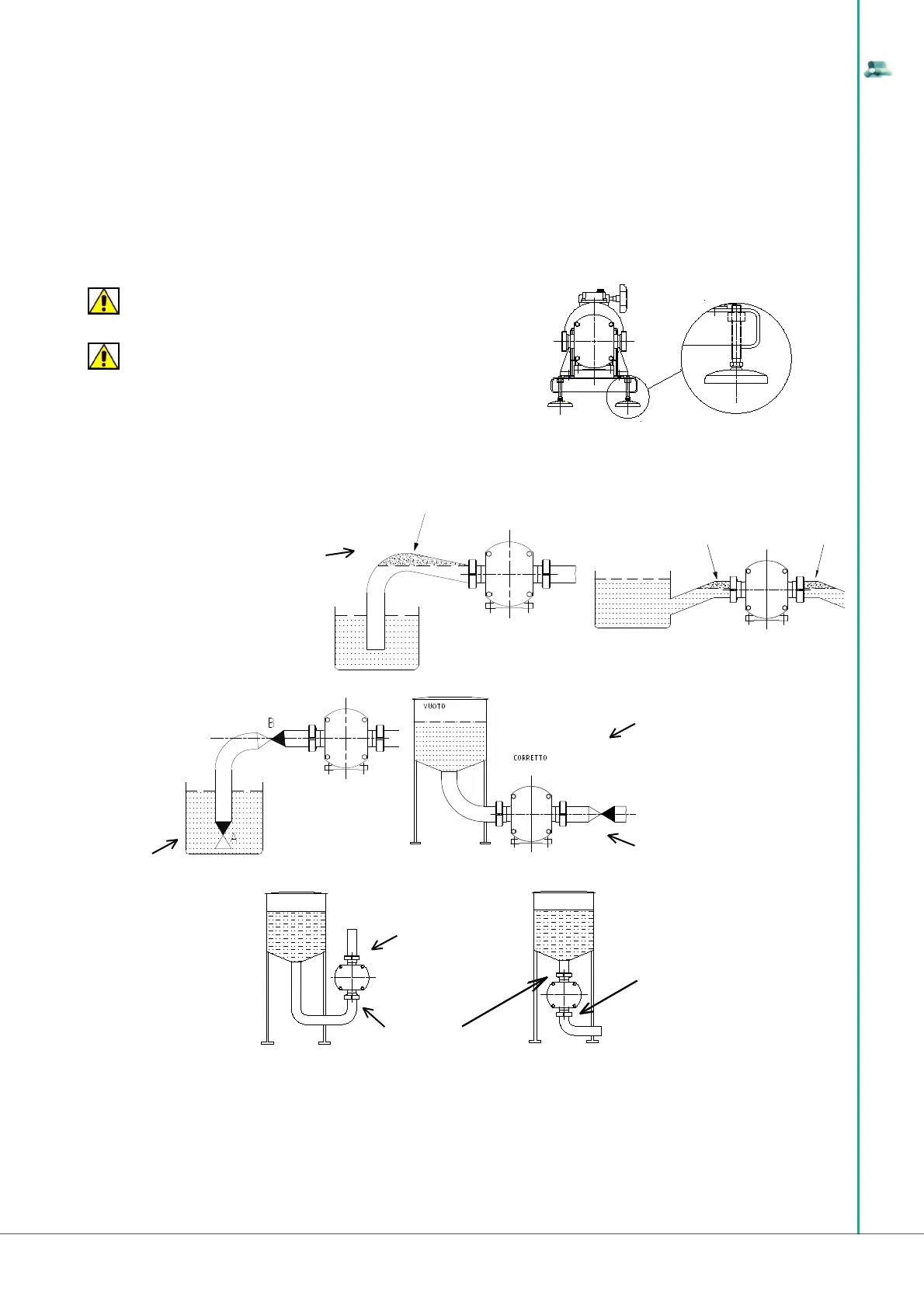

ATTENTION

Check that there are the special non-slip rubber rings in the feet.

ATTENTION

Ensure the Customer plant is aligned properly with the suction

and delivery openings of the LDPU.

When installing the LDPU it is essential to leave a enough space for maintenance and possible removal.

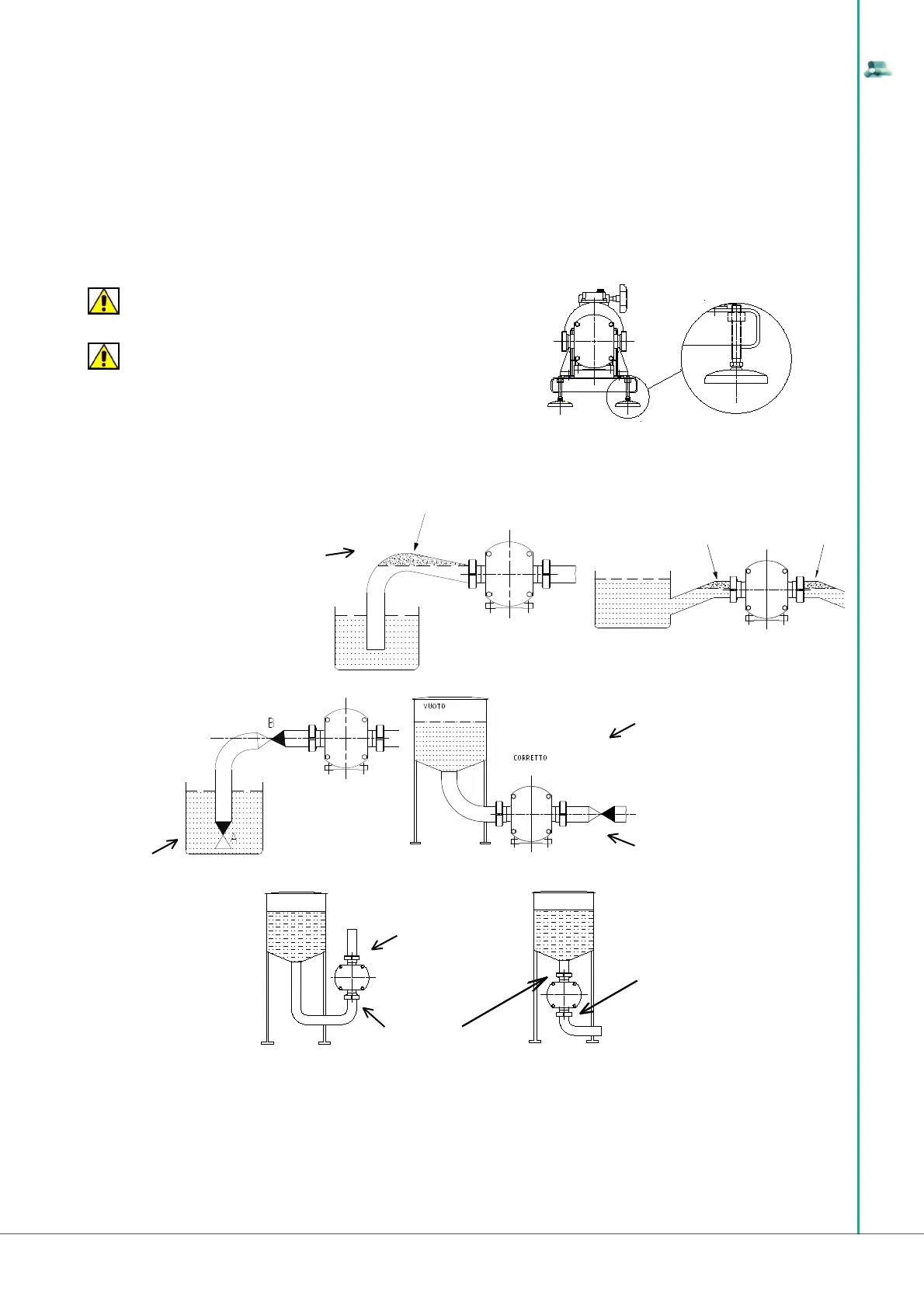

During STAGE 1 relating to the POSITIONING it is recommended to avoid the followings situations:

STAGE 2: FIXING AND INSTALLATION ON SITE

Once the LDPU has been positioned and aligned to the Customer plant, proceed to fi x and install in the plant. Since fi xing between the plant and the

LDPU involves the suction inlet and delivery outlet of the pumping body, listed below are the maximum values of forces and moments, indicated with EF

and EM, which the pump body and consequently the LDPU, of which it is a part, can sustain, as maximum values, during standard operation.

• in the event there are horizontal

tracts of suction piping, make sure these are

slightly inclined upwards to prevent air pockets

from forming which would inhibit perfect priming

of the LDPU;

WRONG!!!

AIR

AIR

WRONG!!!

AIR

• if the

LDPU is not un-

der the head, in

the suction tract

provide a foot or

check valve to

maintain priming;

• if the LDPU is connected to a

vacuum tank, one must reduce the load

leaks due to the suction piping as much

as possible;

• install a check valve on the

delivery tract to prevent the back-fl ow of

air or liquid during interruptions of servi-

ce in order to maintain the pipes com-

pletely full and to facilitate starting when

loaded.

RIGHT!!!

A = foot valve

or

B = check valve

RIGHT!!!

• when applying in ver-

tical position avoid connecting

the suction inlet to the lower side

and the delivery outlet to the

upper side. The proper confi gu-

ration consists in connecting the

suction pipe to the upper side

and the delivery pipe to the lower

side.

WRONG!!!

DISCHARGE

SUCTION

RIGHT!!!

DISCHARGE

SUCTION

Loading...

Loading...