O.M.A.C. s.r.l.

Via Giovanni Falcone, 8 42048 Rubiera (RE) - Italy Tel.0522/629371 - 629923 Fax 0522/628980

Rev.4 del 01/2011 O.M.A.C. s.r.l.

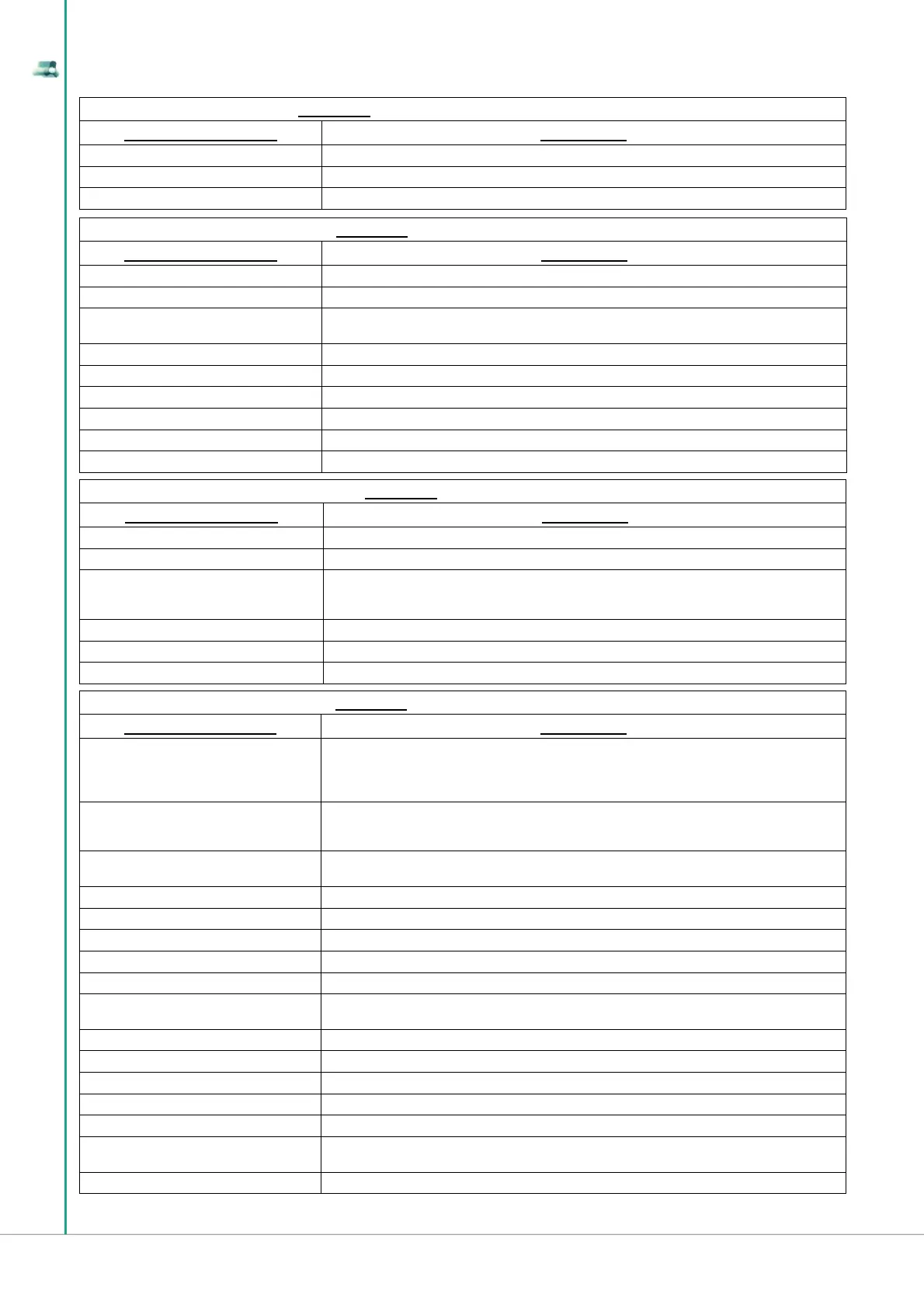

FAILURE: UNPRIMED OF THE PUMP (follow)

POSSIBLE CAUSES: REMEDIES:

Excessive medium viscosity Decrease the speed of the pump, increase the temperature of the medium

Too loose packing gland Tighten the packing gland rightly (see instructions)

Excessive pump speed Decrease the speed of the pump

FAILURE: SEIZURE OF THE PUMP

POSSIBLE CAUSES: REMEDIES:

Excessive medium temperature Decrease the temperature of the medium, cool the pumping case

Presence of suspended particles in the medium

Clean suction piping and install a fi lter on it

Excessive back-pressure

Remove possible obstructions in the outlet piping, increase the piping diameter, reduce its lenght and the number of the

bends

Too tight packing gland Loosen the packing gland and tighten it rightly (see instructions)

Piping press on pumping case Check the piping alignement, if necessary fi t fl exible expansion joints, and fi x the piping on the plant structure

Worn out bearings Replace the bearings by the manufacturer

Worn out or untimed gears Replace the gears or time them according to the instructions

Wrong quantity / quality of gears oil Act according to the manufacturer’s instructions

Parts in contact in the pumping case Check the design pressure coincides with the operating pressure

FAILURE: NO FLOW-RATE

POSSIBLE CAUSES: REMEDIES:

Wrong rotation direction Invert the rotation direction

Unprimed pump Fill pumping case and feeding piping with liquid, expelling air

Insuffi cient N.P.S.H (Net Positive Suction Head)

Increase the head, the piping inlet diameter, reduce the suction piping lenght and the number of the bends, decrea-

se the speed of the pump and the temperature of the medium, check that the increase (caused by the decreasing

temperature) is suitable to the motor power

Presence of air in the suction Increase medium level, lower suction opening position

Dirty or blocked valve or suction fi lter Clean fi lters

The relief valve leaks Check the relief valve setting, clean sealing parts, substitute worn parts

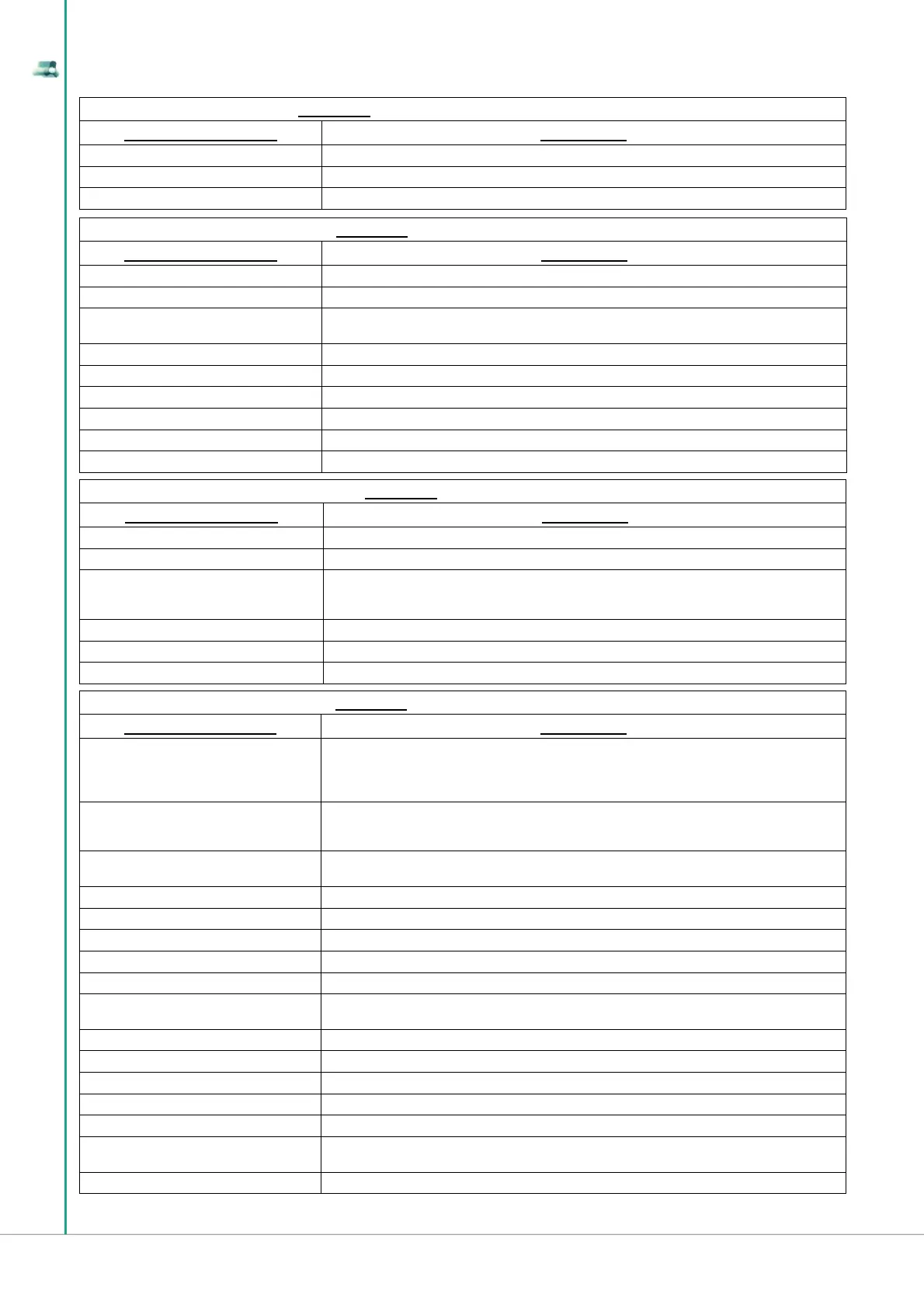

FAILURE: LDPU LOW FLOW-RATE

POSSIBLE CAUSES: REMEDIES:

Insuffi cient N.P.S.H (Net Positive Suction Head)

Increase the head, the piping inlet diameter, reduce the suction piping lenght and the number of the bends, decrea-

se the speed of the pump and the temperature of the medium, check that the increase (caused by the decreasing

temperature) is suitable to the motor power

Medium evaporates in inlet

Increase the head, the piping inlet diameter, reduce the suction piping lenght and the number of the bends, decrea-

se the speed of the pump and the temperature of the medium, check that the increase (caused by the decreasing

temperature) is suitable to the motor power

Air enters in inlet Check and tighten suction piping connections, tighten the packing glands and, if necessary, replace them

Presence of air in the suction Fill pumping case and feeding piping with liquid, expelling air

Not enough liquid level in the tank in the suction Increase medium level, lower suction opening position

Dirty or blocked valve or suction fi lter Clean fi lters

Insuffi cient medium viscosity Increase pump speed, decrease the temperature of the medium

Excessive medium temperature Decrease the temperature of the medium, cool the pumping case

Excessive back-pressure

Remove possible obstructions in the outlet piping, increase the piping diameter, reduce its lenght and the number of the

bends

Too loose packing gland Tighten the packing gland rightly (see instructions)

Insuffi cient pump speed Increase pump speed

Transmission belt slips Stretch the belt

Worn out rotors Replace rotors

The relief valve leaks Check the relief valve setting, clean sealing parts, substitute worn parts

The relief valve is wrongly set

Check the relief valve setting and the spring compression in the way that the spring will open at a 10% more of the

operating pressure

The relief valve vibrates Check the relief valve setting, check and clean the valve

Loading...

Loading...