4-52

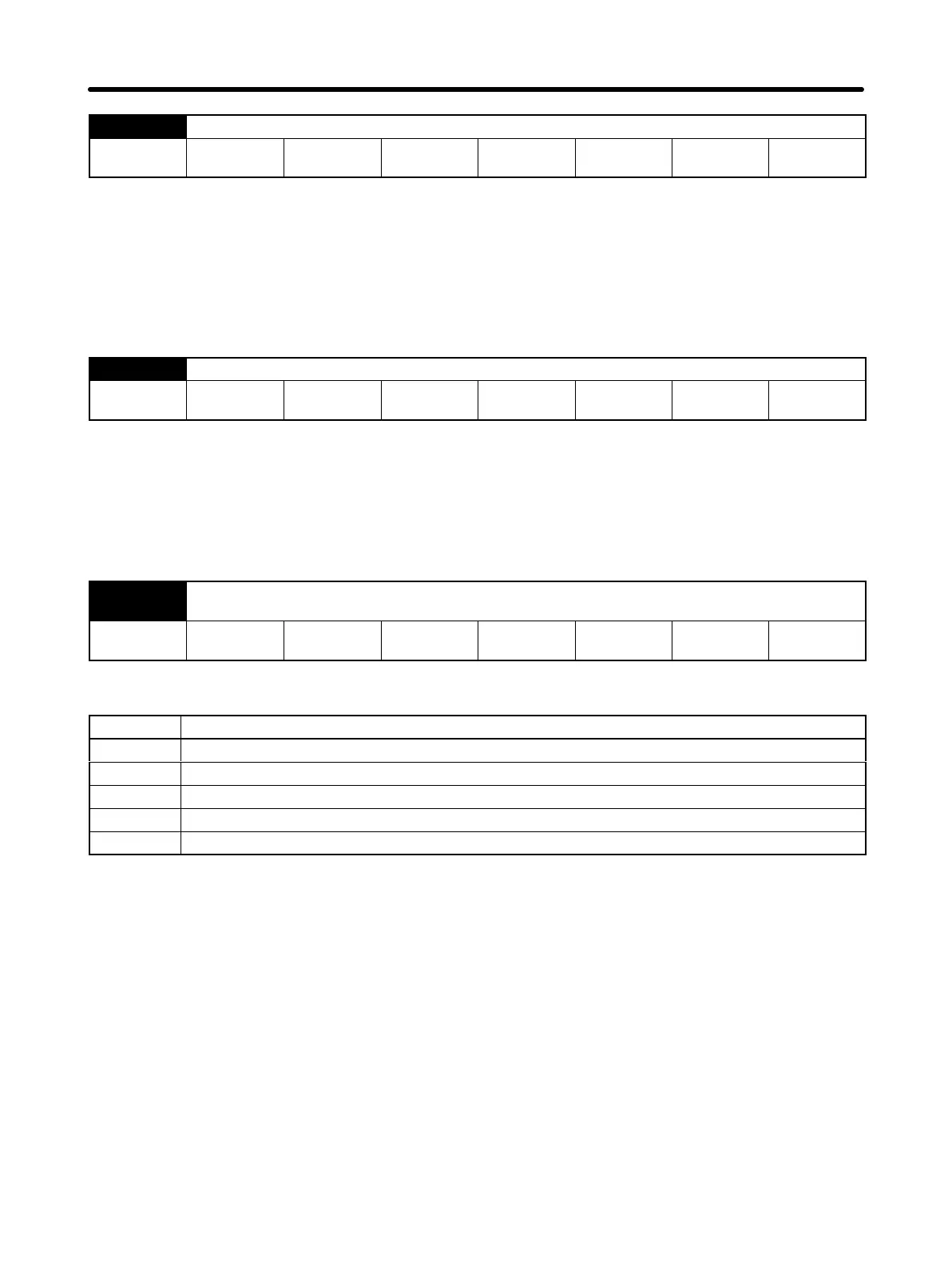

Pn109 Feed-forward amount (Position)

Setting

range

0 to 100 Unit % Default

setting

0 Restart

power?

No

• Sets the feed-forward compensation value during positioning.

• When performing feed-forward compensation, the effective servo gain rises, improving responsive-

ness. There is almost no effect, however, on systems where the position loop gain is sufficiently high.

• Use to shorten positioning time.

Note Setting a high value may result in machine vibration. Set the feed-forward amount for general

machinery to 80% maximum. (Check and adjust machine response.)

Pn10A Feed-forward command filter (Position)

Setting

range

0 to 6400 Unit x 0.01 ms Default

setting

0 Restart

power?

No

• Sets the feed-forward primary (lag) command filter during position control.

• If the positioning completed signal is interrupted (i.e., repeatedly turns ON and OFF) because of per-

forming feed-forward compensation, and a speed overshoot is generated, alleviate the problem by

setting the primary lag filter.

D Speed Control Setting (Pn10b: Default Setting 0004)

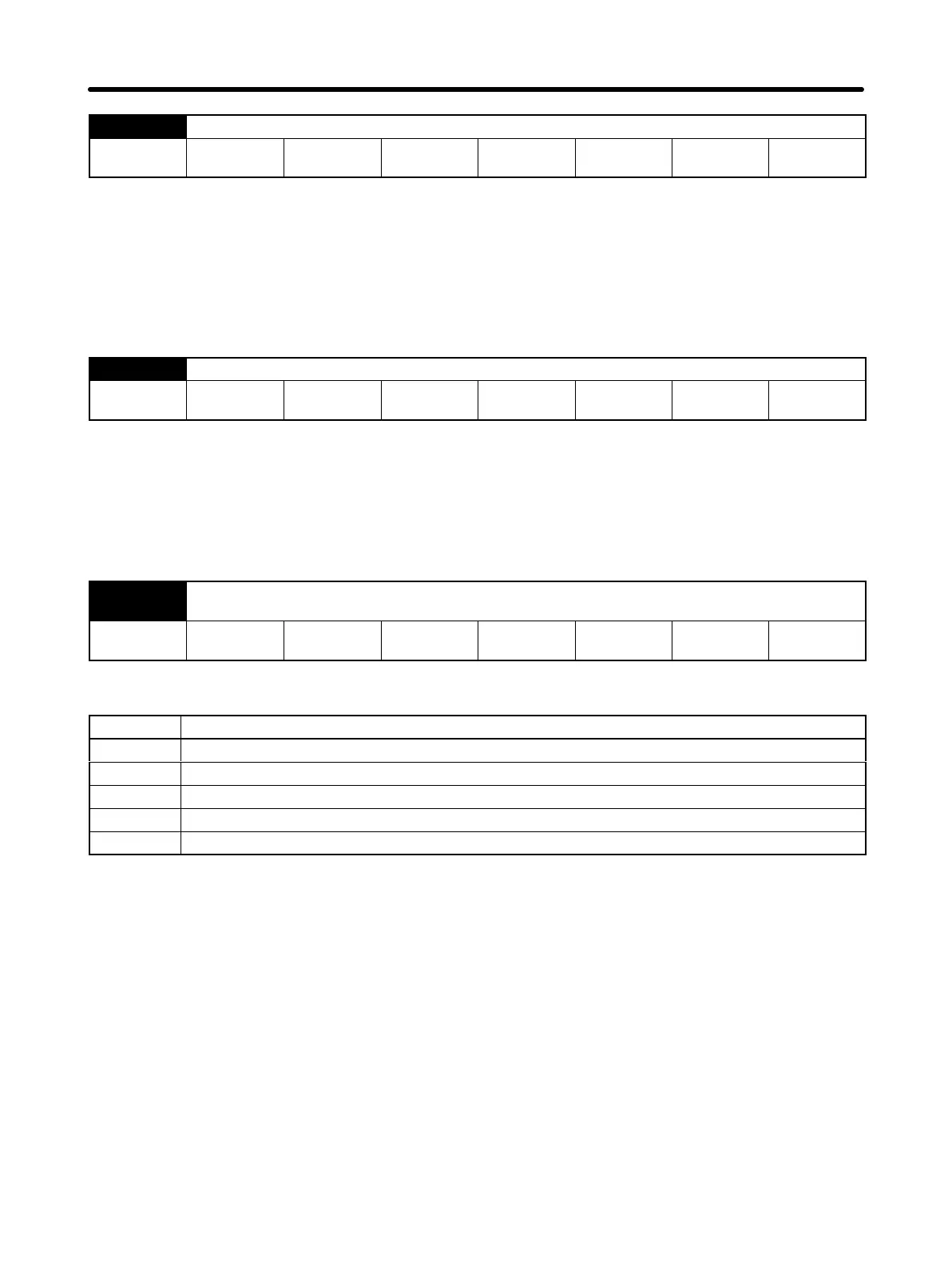

Pn10b.0 Speed control setting –– P control switching conditions (Position, speed, internally-set speed

control)

Setting

range

0 to 4 Unit --- Default

setting

4 Restart

power?

Yes

Setting Explanation

Setting Explanation

0 Internal torque command (Pn10C) condition (Position, speed, internally-set speed control)

1 Speed command (Pn10d) condition (Position, speed, internally-set speed control)

2 Acceleration command (Pn10E) condition (Position, speed, internally-set speed control)

3 Deviation pulse (Pn10F) condition (Position)

4 P control switching function not used. (Position, speed, internally-set speed control)

• Sets the speed control loop switching function from PI control to P control.

• Normally, using the speed loop gain and the position loop gain set by means of the auto-tuning opera-

tion will provide adequate control. (Consequently, there is normally no need to change the setting.)

• When PI control is always being used, switching to P control may help if the Servomotor speed over-

shoots or undershoots (i.e., the effective servo gain is reduced by switching to P control to stabilize the

servo system). The positioning time can also be shortened in this way.

• If the output torque is saturated during acceleration and deceleration, set speed control to 0 (switching

by internal torque command), or 2 (switching by acceleration command).

• If the speed control overshoots or undershoots without the output torque being saturated during accel-

eration and deceleration, set speed control to 1 (switching by speed command), or 3 (switching by

deviation pulse value).

• If the setting is made from 0 to 3 (i.e., if P control switching is used), set the switching condition to

Pn10C to Pn10F.

Operation Chapter 4

Loading...

Loading...