2-25

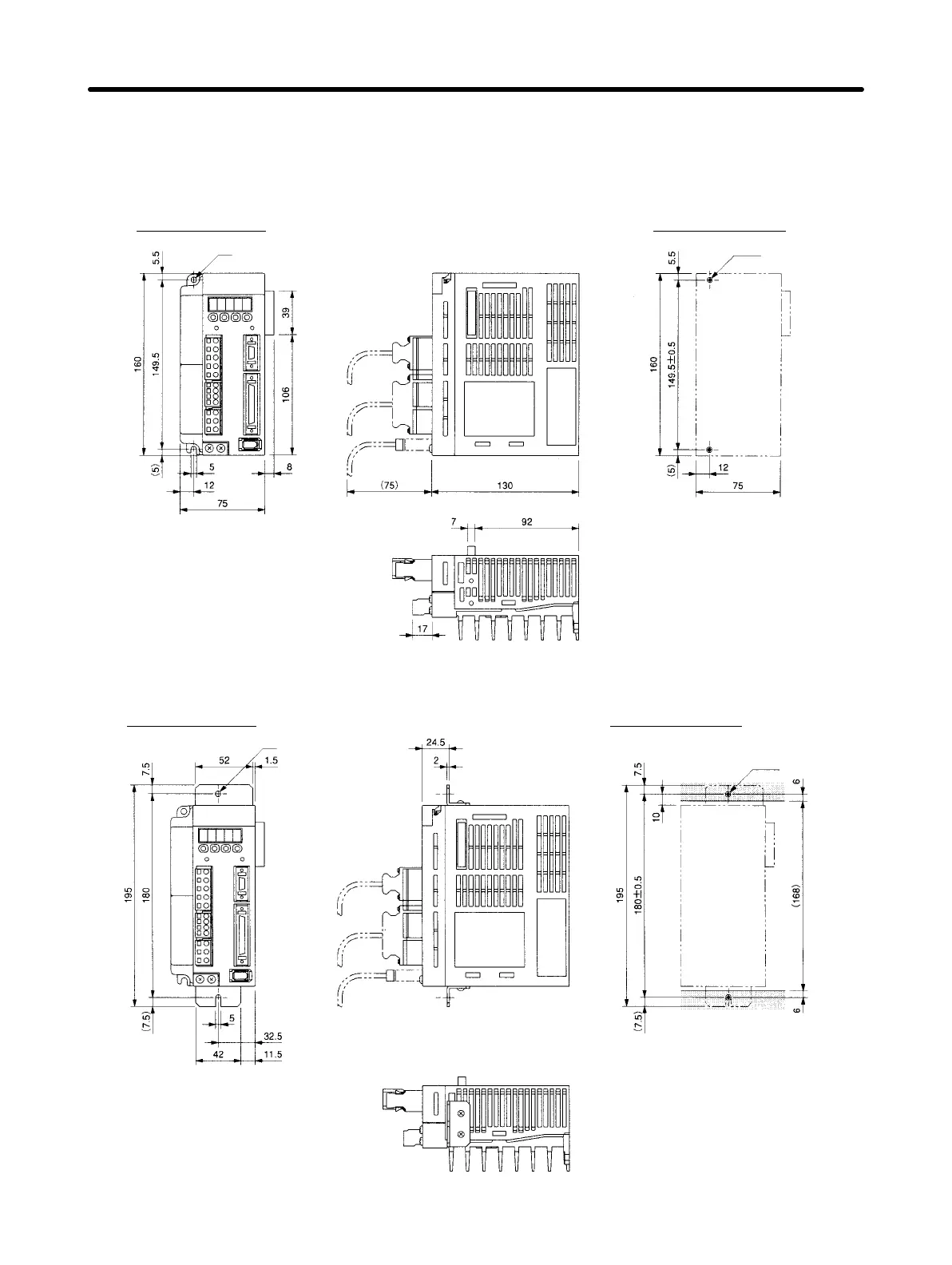

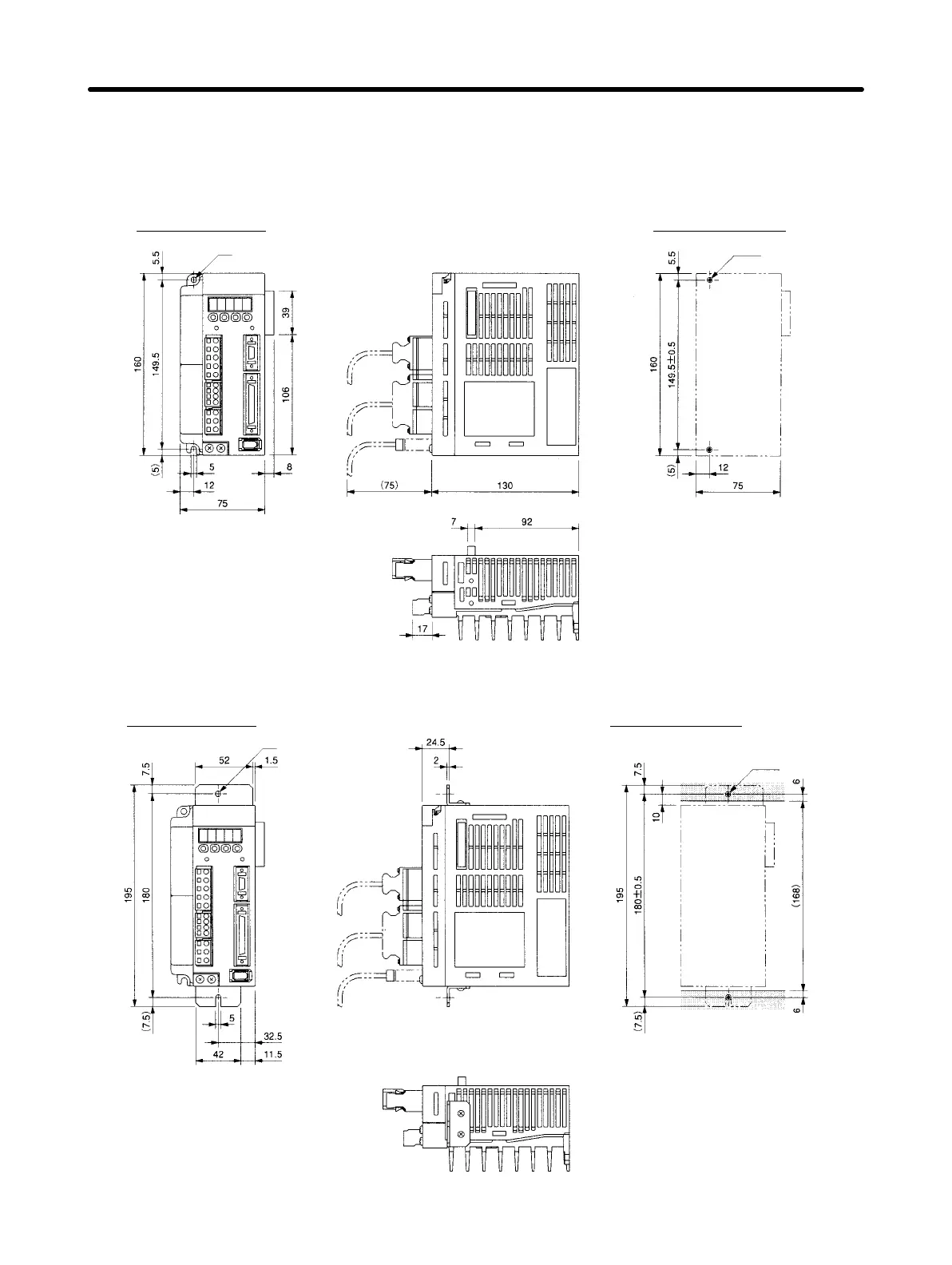

H Single-phase 100 V: R88D-WT02HL (200 W)

Single-phase 200 V: R88D-WT04H (400 W)

D Wall Mounting

5 dia. Two, M4

External dimensions Mounted dimensions

D Front Panel Mounting (Using Mounting Brackets)

5 dia.

Two, M4

External dimensions Mounted dimensions

Standard Models and Specifications

Chapter 2

Loading...

Loading...