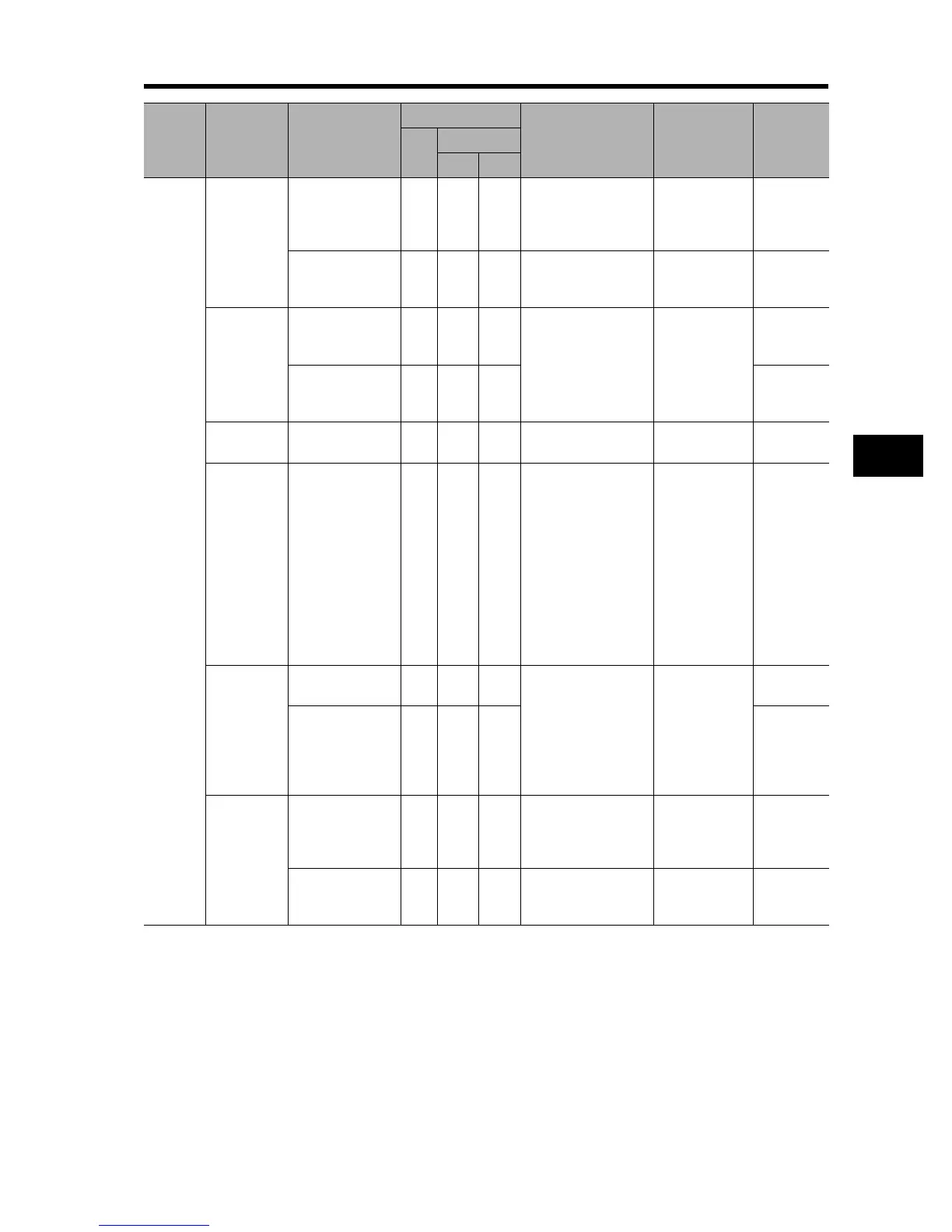

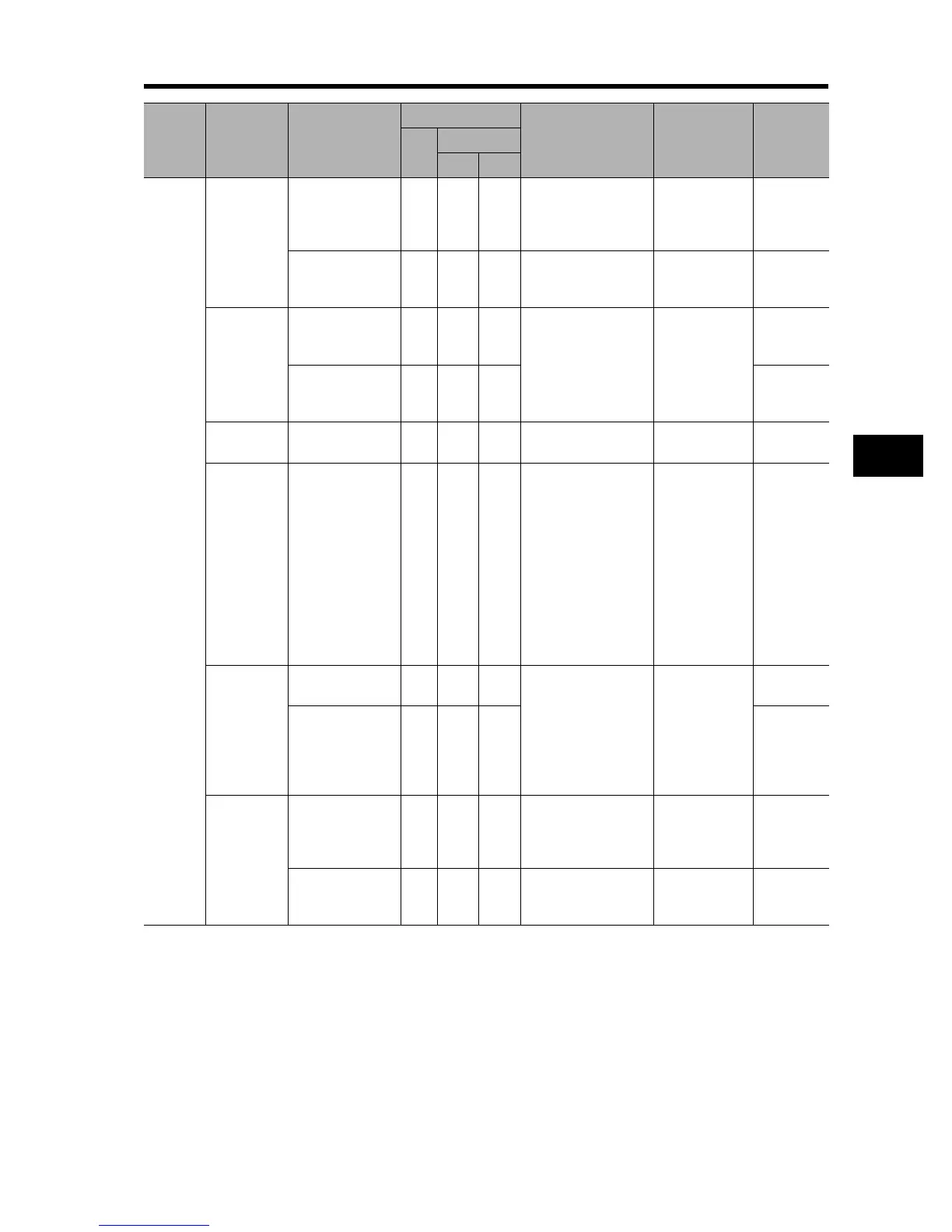

6-4

6-1 Inspection and Maintenance

6

Inspection and Maintenance

Main

circuit

General

Check that any

parts which may

need tightening

are secure.

{ Tighten securely. No faults

Check that no part

has indications of

overheating.

{ Visual inspection No faults

Connection

conductor

and wire

Check that there is

no distortion with

the conductor.

{

Visual inspection No faults

Check that there is

no damage to the

wire Insulation.

{

Terminal

block

Check that there is

no damage.

{ Visual inspection No faults

Inverter unit

Converter

unit

(including

the resistor)

Check the

resistance

between the

terminals.

{

Disconnect the wiring

of the Inverter main

circuit terminal block

and measure the

resistance levels

between terminals

R/L1, S/L2, T/L3 and

P/+, N/-, and between

U/T1, V/T2, W/T3 and

P/+, N/- in the range

of tester ×

1 .

Refer to

"Checking the

Inverter and

Converter".

Inverter unit

replacement

reference

Start/Stop:

Cycle 10

6

*3

Analog

tester

Smoothing

capacitor

Check that there is

no liquid leakage.

{

Visual inspection

No faults

Reference of

the replacement

period: 10 years

*2 *3

Capacity

meter

Check that the

safety valve has

not come out and

that there are no

bulges.

{

Relay

Check that there is

no abnormal

sound during

operation.

{ Acoustic inspection No faults

Check that there is

no rough surface

on the contact.

{ Visual inspection No faults

Inspection

part

Inspection

item

Inspection point

Inspection period

Inspection method Criteria Meter

Daily

Periodic

1 year 2 years

*1. The life of the smoothing capacitor depends on ambient temperature.

Refer to "Appendix-2 Product Life Curve" for the replacement reference.

*2. The life of the cooling fan varies depending on the environmental conditions, such as ambient temperature

and/or dust. Check the operation through daily inspections.

*3. The replacement reference (year/cycle) or "

Appendix-2 Product Life Curve" is based on the expected design

life, which is not guaranteed.

Loading...

Loading...