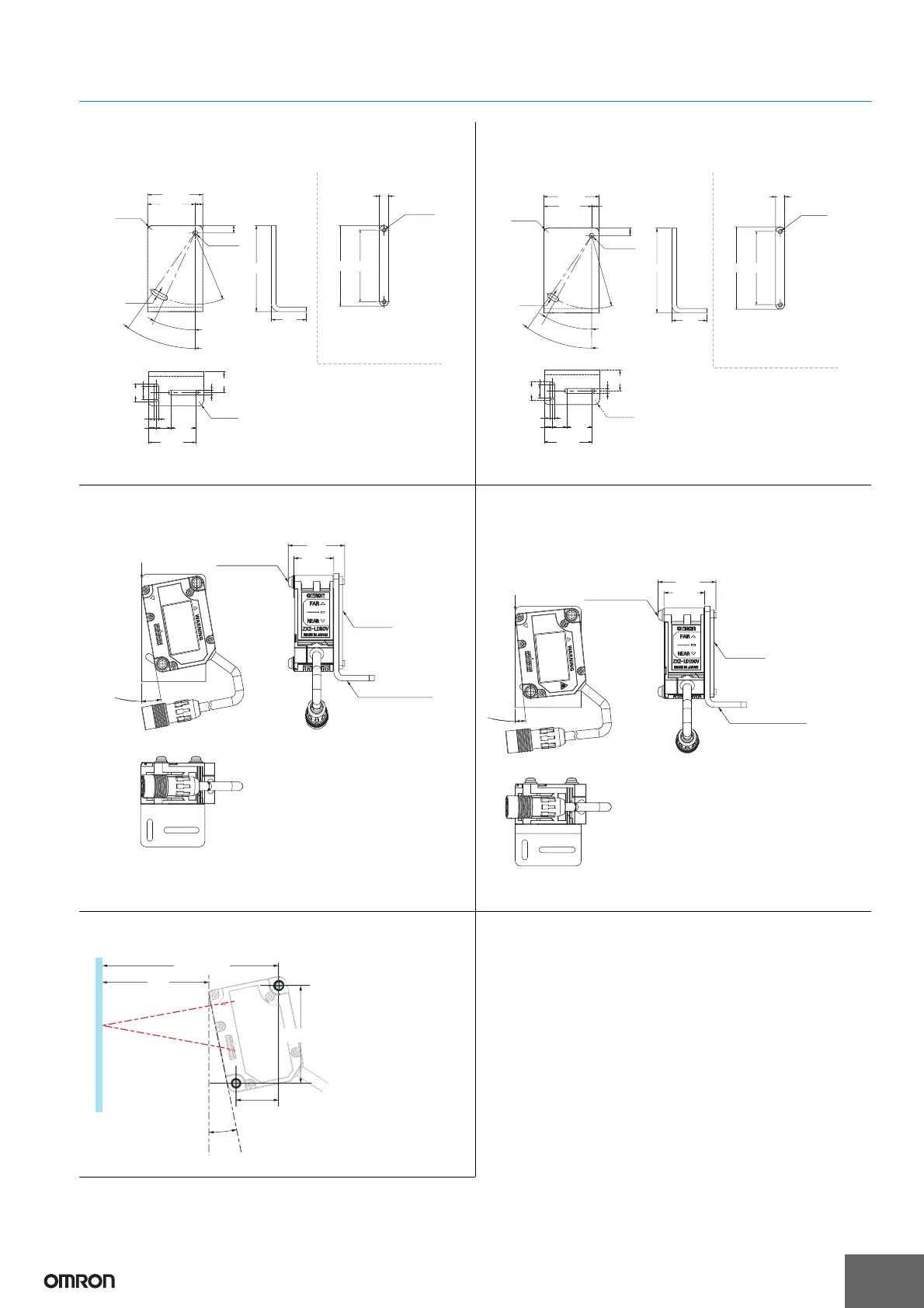

Material: Stainless steel

(SUS304)

Thickness: 2.0 mm

Material: Stainless steel (SUS304)

Thickness: 3.0 mm

Accessories: Phillips screws (M3×30): 2

Nut plate: 1

Nut plateMounting Bracket

R48.1

3.2 dia.

5

5

31.4

(36.4)

58

23

3.5

2-R3

54.1

48.1

2

-

M3

P=0.5

24.5°

(Regular-reflective

Sensor mounting)

34.7°

(Diffuse-reflective

Sensor mounting)

6

2-R3

14

3.2

3.2

5.2

12

8.8

16.8

16.8

16.8

(26.4)

9.6

*

Nut plate

Use this Mounting Bracket when installing the ZX2-LD100 (L) as a normal

Diffuse-reflective or Regular-reflective Sensor Head.

Material: Stainless steel

(SUS304)

Thickness: 2.0 mm

Material: Stainless steel (SUS304)

Thickness: 3.0 mm

Accessories: Phillips screws (M3×30): 2

Nut plate: 1

Mounting Bracket

3.5

54.1

48.1

2-M3

P=0.5

R48.1

5

5

31.6

(36.6)

56

23

2-R3

3.2 dia.

29.2°(Regular-reflective

Sensor mounting)

34.7°(Diffuse-reflective

Sensor mounting)

6

2-R3

14

3.2

12

8.8

3.2

5.2

16.8

16.8

16.8

(26.4)

9.6

Mounting Bracket

Nut plate

Phillips screws

22.6

10.5°

*

2

*

1

(32)

Installation Method for Regular-reflective Sensor Head

Using a E39-L178 Mounting Bracket:

Note:

When securing the Sensor Head in the

Mounting Bracket, insert the screws into

the side of the Sensor Head where the

warning label is located and secure the

Sensor Head into place.

*1. The measurement distance reference

position is the end of the Mounting Bracket.

*2. For the Regulalr-reflective Sensor Heads,

rotate the Sensor Head counterclockwise,

secure it in place, and then perform any

necessary fine adjustments.

Mounting Bracket

Nut plate

Phillips screws

(32)

22.6

*

2

*

1

5.75°

Installation Method for Regular-reflective Sensor

Heads (Installing a Diffuse-reflective Sensor

Head as a Regular-reflective Sensor Head)

Using a E39-L179 Mounting Bracket:

Note:

When securing the Sensor Head in the

Mounting Bracket, insert the screws into the

side of the Sensor Head where the warning

label is located and secure the Sensor Head

into place.

*1. The measurement distance reference position is

the end of the Mounting Bracket.

*2. For the IInstalling a Diffuse-reflective Sensor as

a Regular-reflective Sensor, rotate the Sensor

Head counterclockwise, secure it in place, and

then perform any necessary fine adjustments.

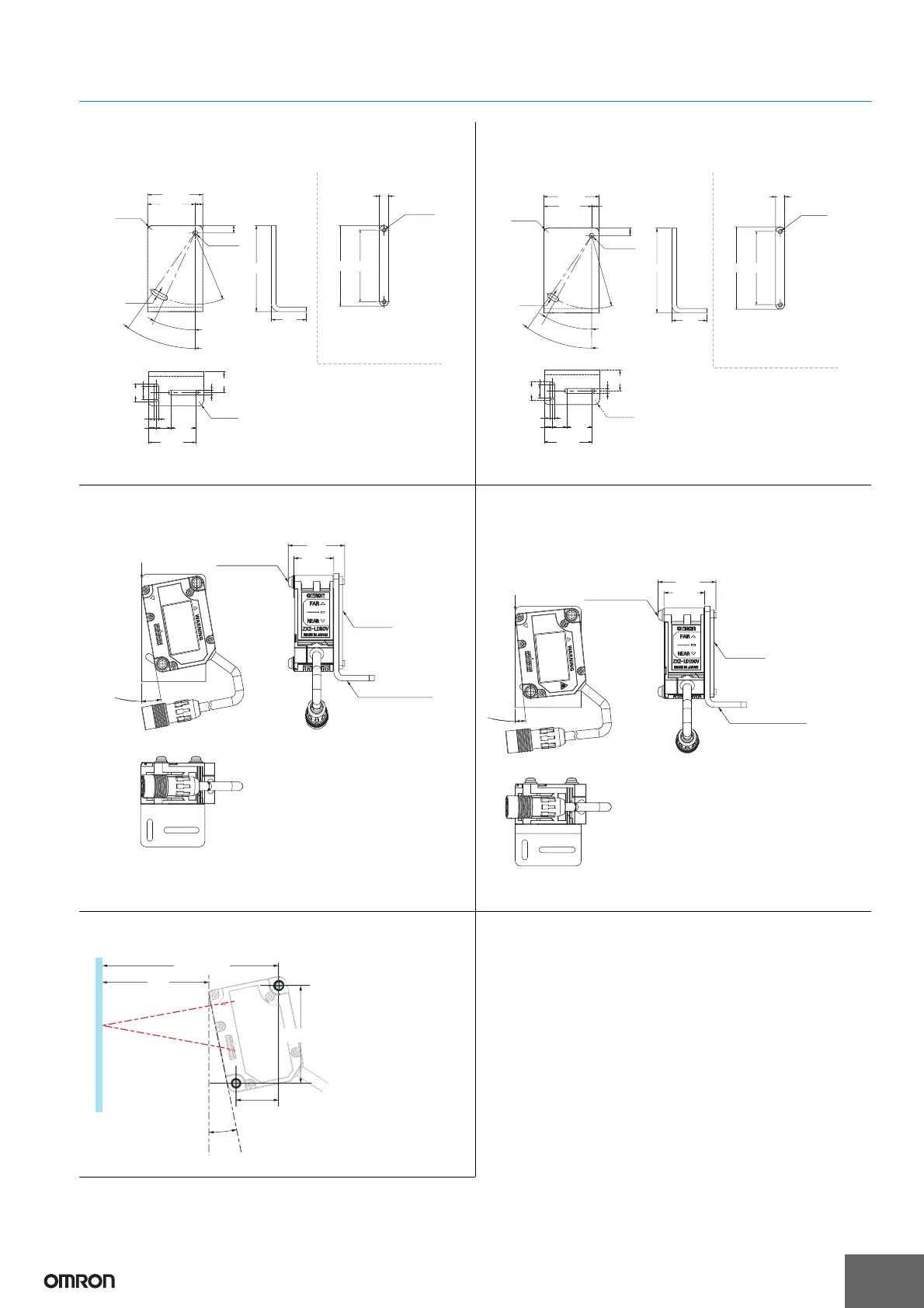

workpiece

Measurement

center distance

10.5°

*

The mounting hole dimensions in parentheses

(reference values) are for when the Sensor is

installed at 10.5°.

Adjust the installation so that the angle is 10.5° ±0.1°.

Not Using a Mounting Bracket:

Tilt the Sensor Head towards the workpiece as shown below.

Loading...

Loading...