29

5.3 Laser Path Alignment

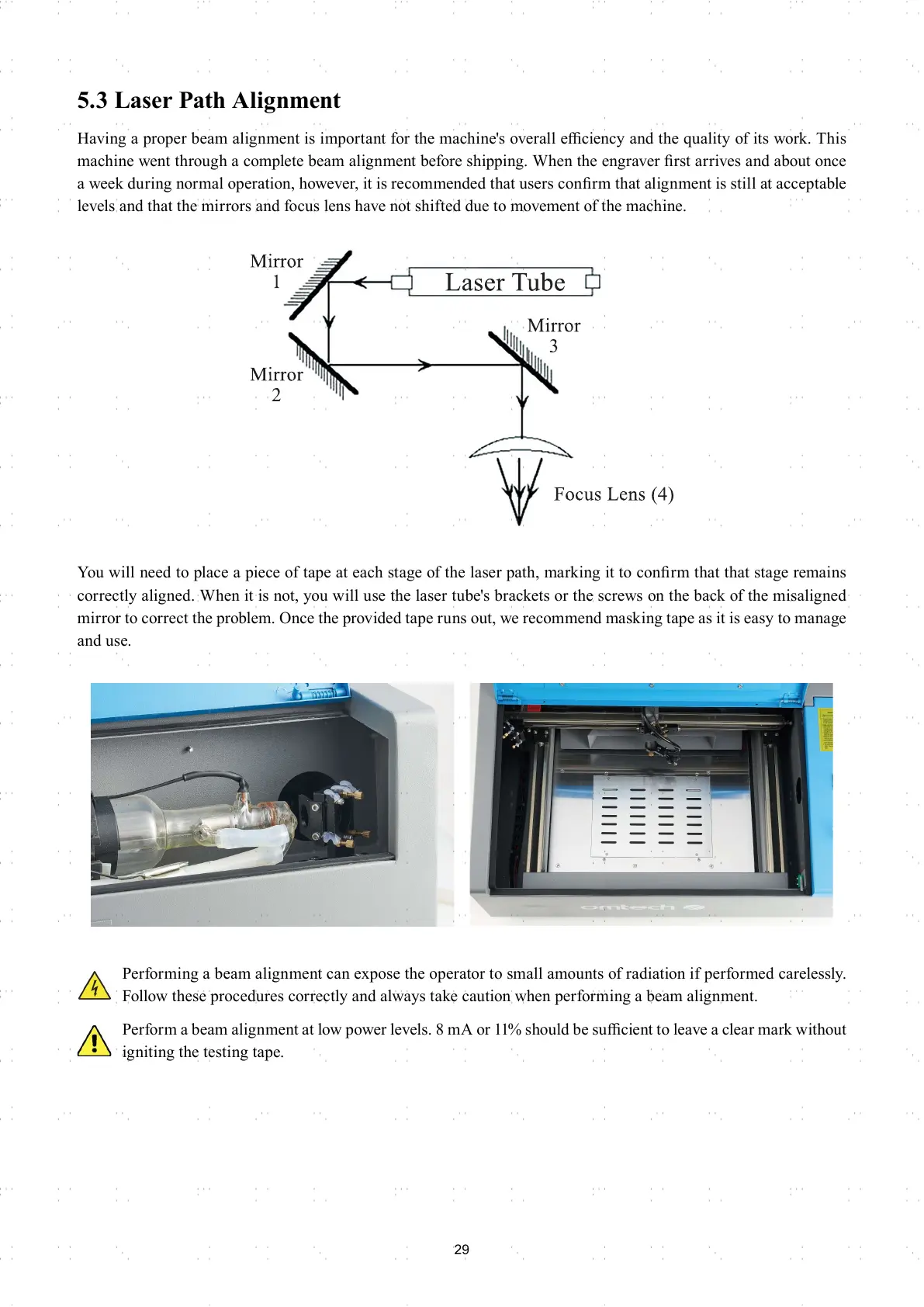

Having a proper beam alignment is important for the machine's overall effi ciency and the quality of its work. This

machine went through a complete beam alignment before shipping. When the engraver fi rst arrives and about once

a week during normal operation, however, it is recommended that users confi rm that alignment is still at acceptable

levels and that the mirrors and focus lens have not shifted due to movement of the machine.

You will need to place a piece of tape at each stage of the laser path, marking it to confi rm that that stage remains

correctly aligned. When it is not, you will use the laser tube's brackets or the screws on the back of the misaligned

mirror to correct the problem. Once the provided tape runs out, we recommend masking tape as it is easy to manage

and use.

Performing a beam alignment can expose the operator to small amounts of radiation if performed carelessly.

Follow these procedures correctly and always take caution when performing a beam alignment.

Perform a beam alignment at low power levels. 8 mA or 11% should be suffi cient to leave a clear mark without

igniting the testing tape.

Loading...

Loading...