46

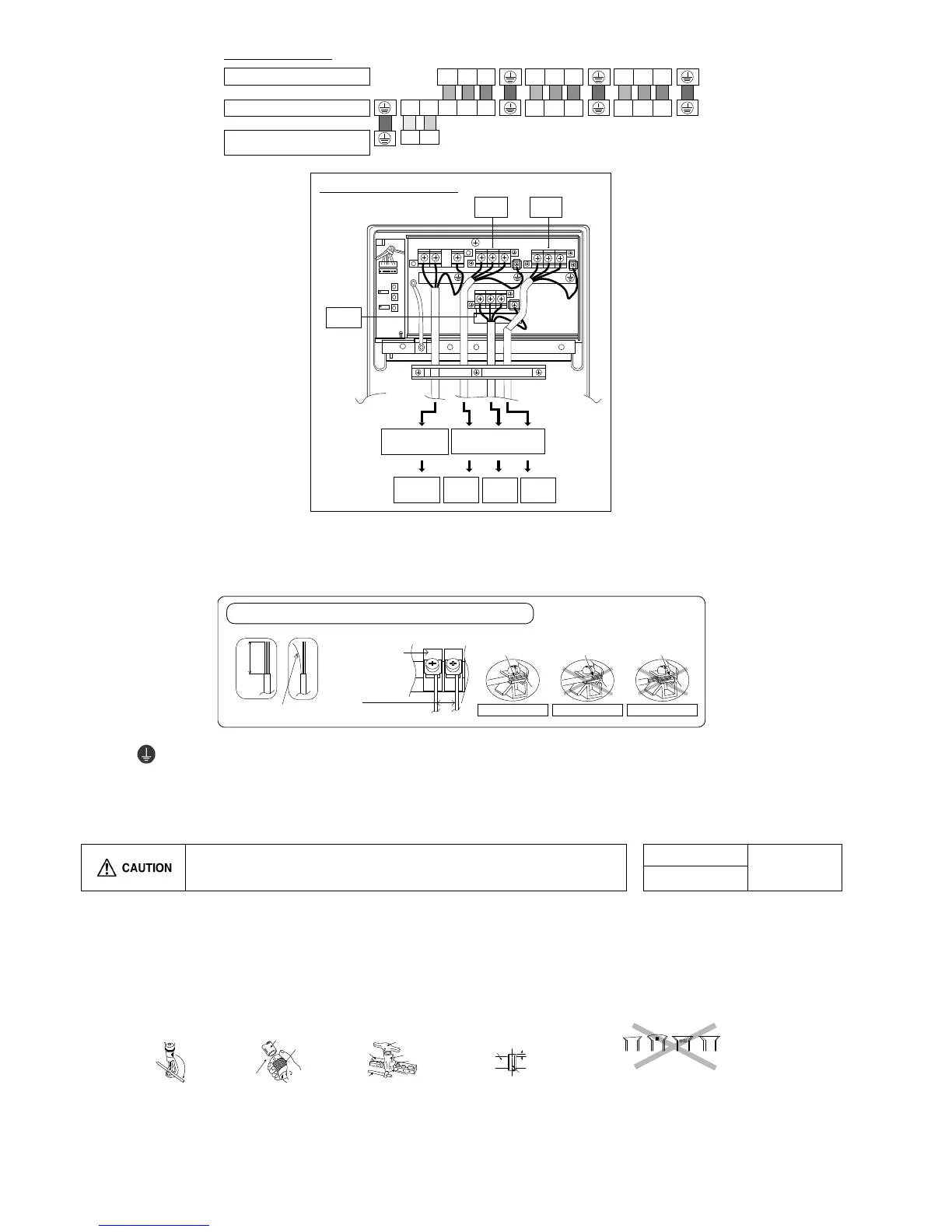

5. For wire stripping and connection requirement, refer to the diagram below.

6. Secure the power supply cord and connecting cables onto the control board with the holder.

7. Attach the control board cover back to the original position with screw.

This equipment must be properly earthed.

Note: Isolating Devices (Disconnecting means) should have minimum 3.0 mm contact gap.

Earth wire shall be Yellow/Green (Y/G) in colour and longer than other AC wires for safety reason.

10.2.6 Heat Insulation

Use a material with good heat-resistant properties as the heat insulation for the

pipes. Be sure to insulate both the gas-side and liquid-side pipes. If the pipes are

not adequately insulated, condensation or water leakages may occur.

Liquid-side pipes

Material shall

withstand

120°C or higher

Gas-side pipes

CUTTING AND FLARING THE PIPING

1. Please cut using pipe cutter and then remove the burrs.

2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder entering the pipe.

3. Please make flare after inserting the flare nut onto the copper pipes.

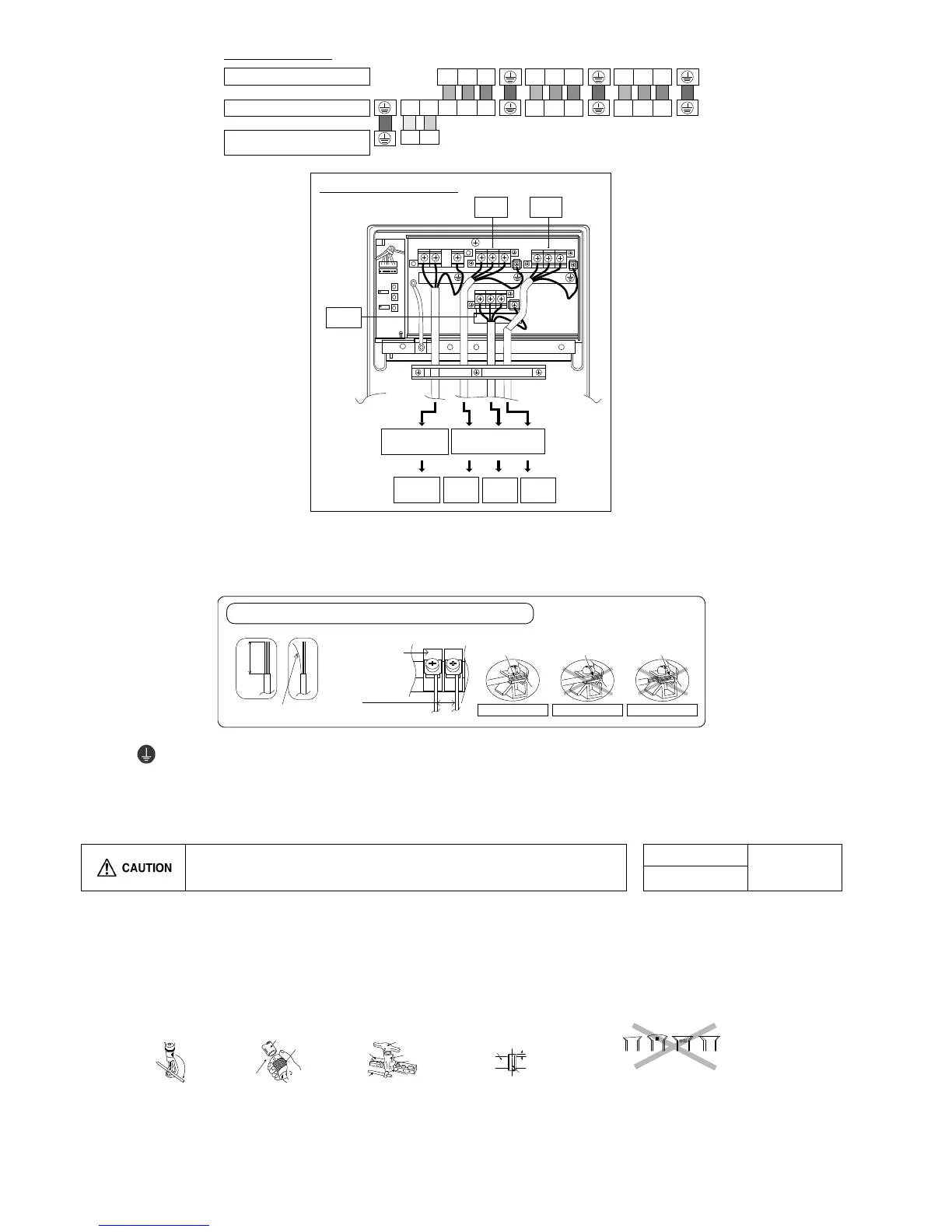

CU-3

***

Colour of wires (Connection cable)

(Power supply cord)

Terminals on the indoor unit

Terminals on the outdoor unit

Terminals on the isolating devices

(Disconnecting m eans)

(UNIT A) (UNIT B)

11

11

L

(L)

22

22

N

(N)

33

33

(UNIT C)

1

1

2

2

3

3

p

CU-3E23***, CU-3RE18***

Indoor & outdoor

connection cable

Unit A Unit B

Unit C

Power Supply

Cord

Isolating

Devices

Indoor

Unit A

Indoor

Unit C

Indoor

Unit B

Wire stripping

(gap between

wires)

Noloosestrandwhen

inserted

Indoor/outdoor

connecting

terminal board

10 ± 1 mm

Conductor fully

inserted

Conductor over

inserted

Conductor not

fully inserted

ACCEPT PROHIBITED PROHIBITED

WIRE STRIPPING AND CONNECTING REQUIREMENT

5mm

or more

ing ■

Inclined Surf ace

damaged

Cracked Une ven

thickness

Bar

Red arrow mark

Handle

Core

Yo k e

Clamp

handle

Bar

0–0.5mm

Copper pipe

When properly flared, the internal surface

of the flare will evenly shine and be of

even thickness. Since the flare part come

into contact with the connections, carefully

check the flare finish.

Reamer

2. To remove burrs 3. To flare

Point down

Pipe

Loading...

Loading...