ETH Mounting Instructions

36 192-550002N10 ETH March 2019

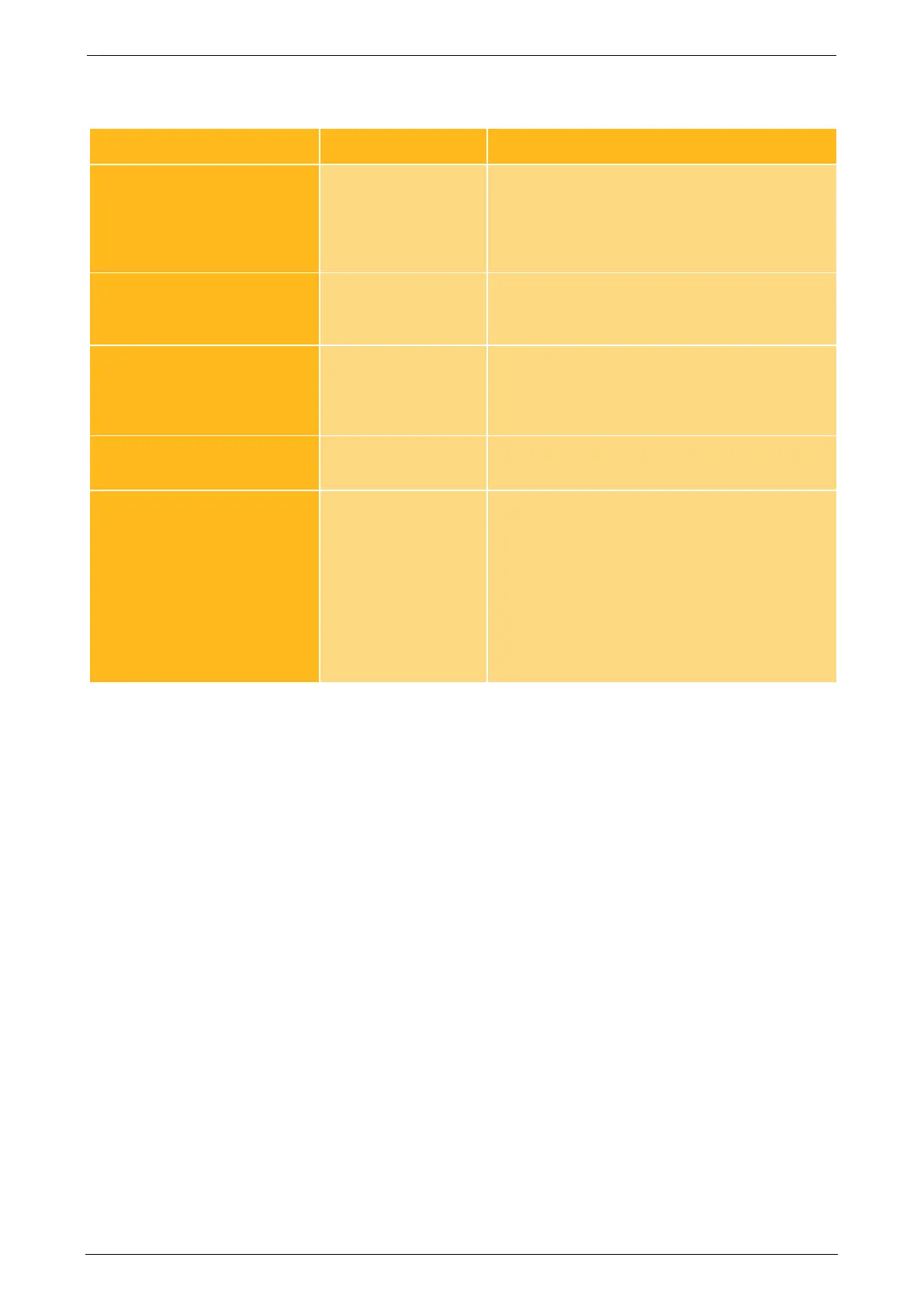

3.1 Maintenance schedule

WHEN WHAT ACTION

The cylinder is furnished completely lubricated.

If the cylinder was held on stock at your premises

for more than 1 year, it must be relubricated

before commissioning.

see lubricating intervals and amount of lubricant

Depending on the mileage,

see table Lubricating intervals

and amount of lubricant (see

page 36)

see lubricating intervals and amount of lubricant

Visual inspection for external damages of the

actuator.

If externally caused damages are visible on the

thrust rod or on the profile, please contact

the customer

Check screw tightening torque.

see mounting tightening torques ETH (see page

Annually, or every 6000 hours of

operation

(with parallel

configuration)

In general, the high performance toothed belts

used in the ETH are maintenance free.

Visual inspection of the timing belt is however

required. Please check the toothed belt for the

following aspects:

Wear at the teeth

Cracks in the tooth root surface

Fractures in the belt back

If you find signs of wear, the toothed belt must be

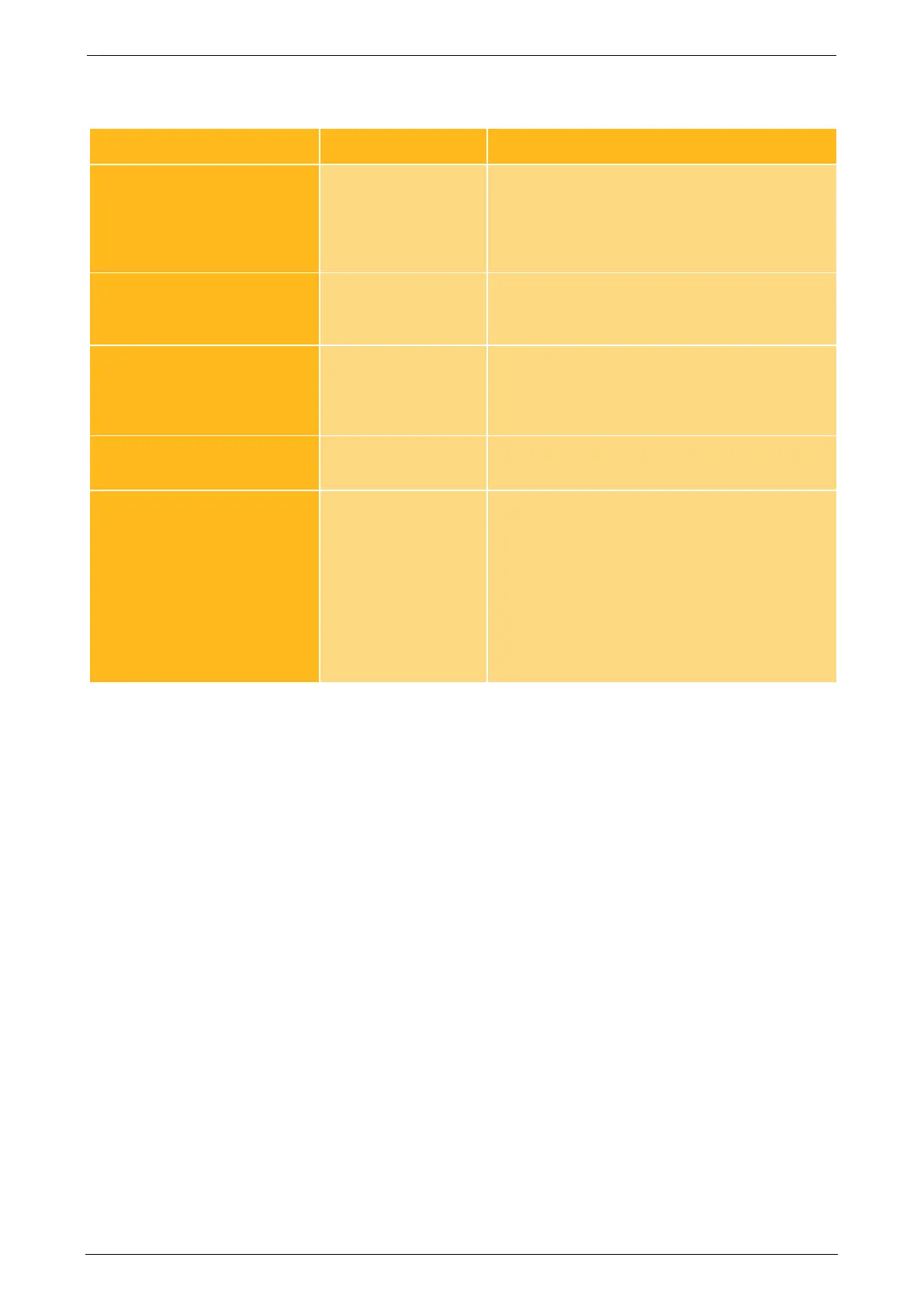

3.2 Lubricating intervals and amount of lubricant

The lubrication intervals depend on the operating conditions (series, pitch, speed,

acceleration, loads, etc.) and the ambient conditions (e.g. temperature). Ambient

influences such as high loads, impacts and vibrations shorten the lubrication

intervals. In short-stroke applications, a lubrication run must be performed after

max. 10 000 movement cycles. In the event of small loads and if the application is

impact and vibration free, the lubrication intervals can be increased.

Under normal operating conditions, the given lubrication intervals apply. If the total

travel per year is shorter than the given intervals, the cylinder must be relubricated

at least once per year. Lubrication is always required if the cylinder will not be used

for a longer period of time or when operation is interrupted! The lubricant used is

supplied by Klüber, it is available worldwide.

Normal operating conditions:

Medium Speed: 0.5 x v

max

Application factor f

w

=1.0

No impacts and vibrations

Load ration F

m

/F

max

: 20 %

Loading...

Loading...