PAGE 42

4.1.2.7 POSITION PROPORTIONING CONTROL

Position Proportioning control can be implemented on those controllers provided with two

SPST relay outputs or two SSR Driver outputs and Slidewire Feedback option.

Positioning proportioning control permits the use of PID control where the final control

element is a modulating device such as a motorized valve. In this form, each of the two

required relays or SSR Drivers will be used to control the valve. One output is used to open

the valve, the other is used to close the valve. The slidewire feedback is used to provide a

signal relative to the valve armature position to the instrument.

As with the other proportioning control forms, the process input, tuning parameters and the

setpoint are used by the control algorithm to calculate the output % requried to correct for the

deviation between setpoint and process.

With Position Proportioning control, it may be necessary to adjust the Sensitivity (SEnS) Tune

mode parameter to reduce or eliminate oscillations of the motor around setpoint. If oscillation

occurs, increase the SEnS value until the motor stops oscillating. If the differential between

the Open and Closed rotation is too large, then decrease the SEnS value. Also, for proper

Position Proportioning operation, it is necessary to specify the actuation time of the valve or

damper from full open to full closed. If the motor has a stroke duration of 60 seconds, change

the value in the Cycle Time parameter Ct1 to 60. This ensures that the controller will move

the motor for the proper amount of time when making adjustments.

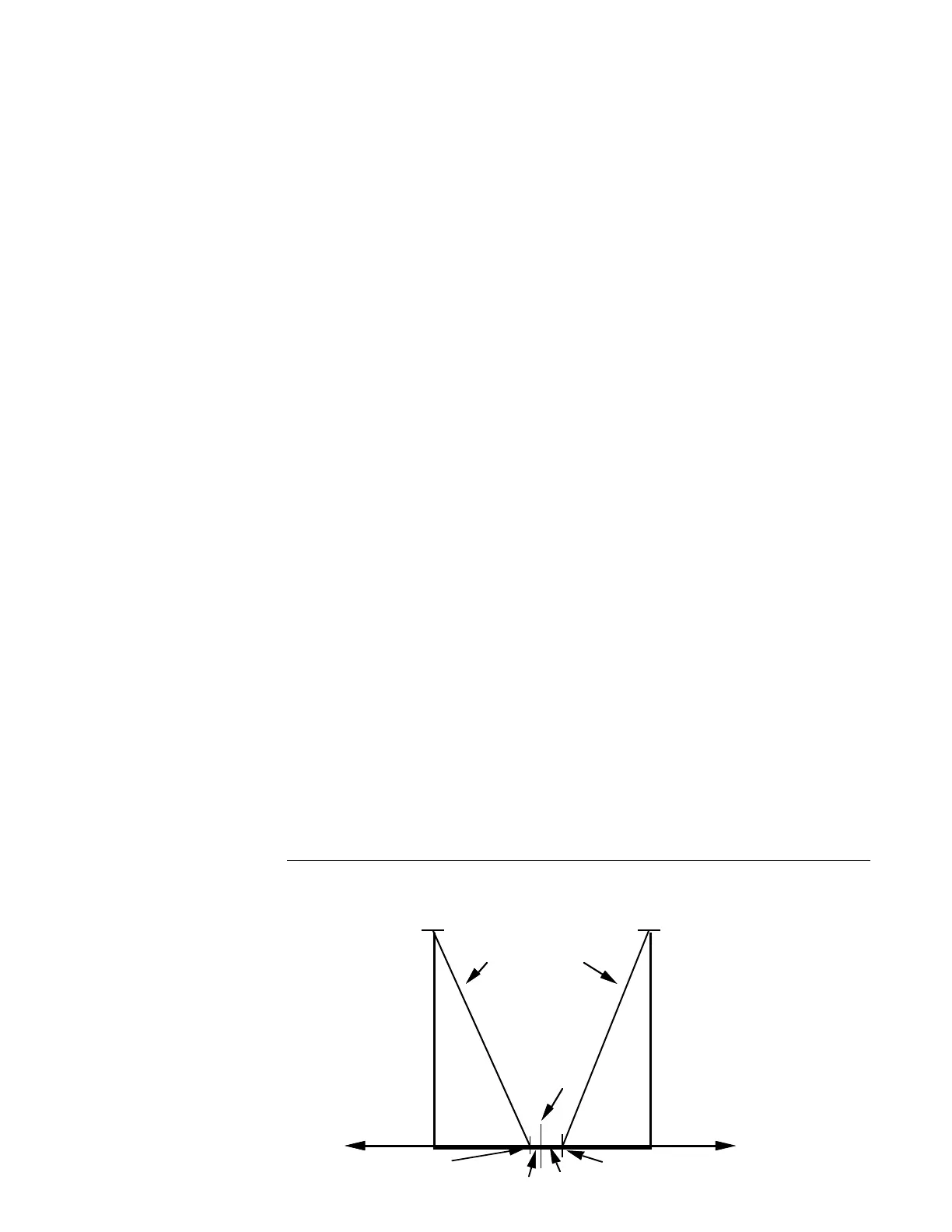

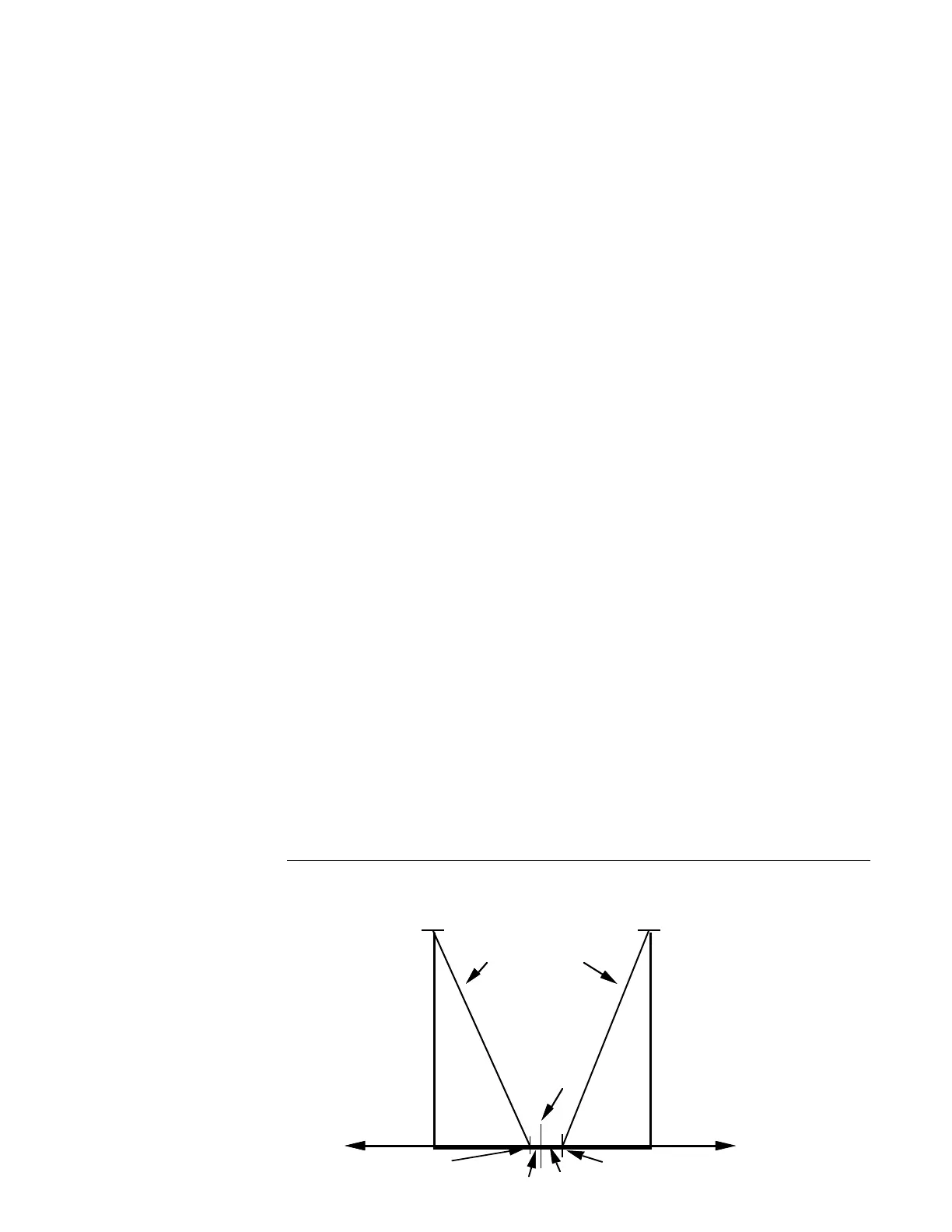

4.1.2.8 DUAL OUTPUT CONTROL

Dual output control can be performed when two outputs are specified. The outputs may be

programmed for On-Off, Time Proportioning, or Current Proportioning, as applicable.

The output action is dependent upon the setpoint, the process value, and Tune mode

parameters. If two proporitonal outputs are selected, both output proportional bands will be

biased so that 0% of output is seen when the process value equals setpoint. The output(s)

can be biased by the use of the Tune mode parameters FOP and SPrd as shown in

Figure 4-1 (below).

The first output is programmed as a proportional reverse output and the second as a propor-

tional direct output. (See Glossary, page 67, for definitions of these terms). Dual proportion-

ing outputs are provided with separate proportional bands and cycle time

adjustments for each output.

FIGURE 4-1

100%

Proportional

Output 1

Reverse

Actin

Output

Direct

Actin

Output

100%

Proportional

Output 2

Control

Setpoint

First

Output

Position = X

Process

Value

+Y

-X

Second

Output

Position = Y

Loading...

Loading...