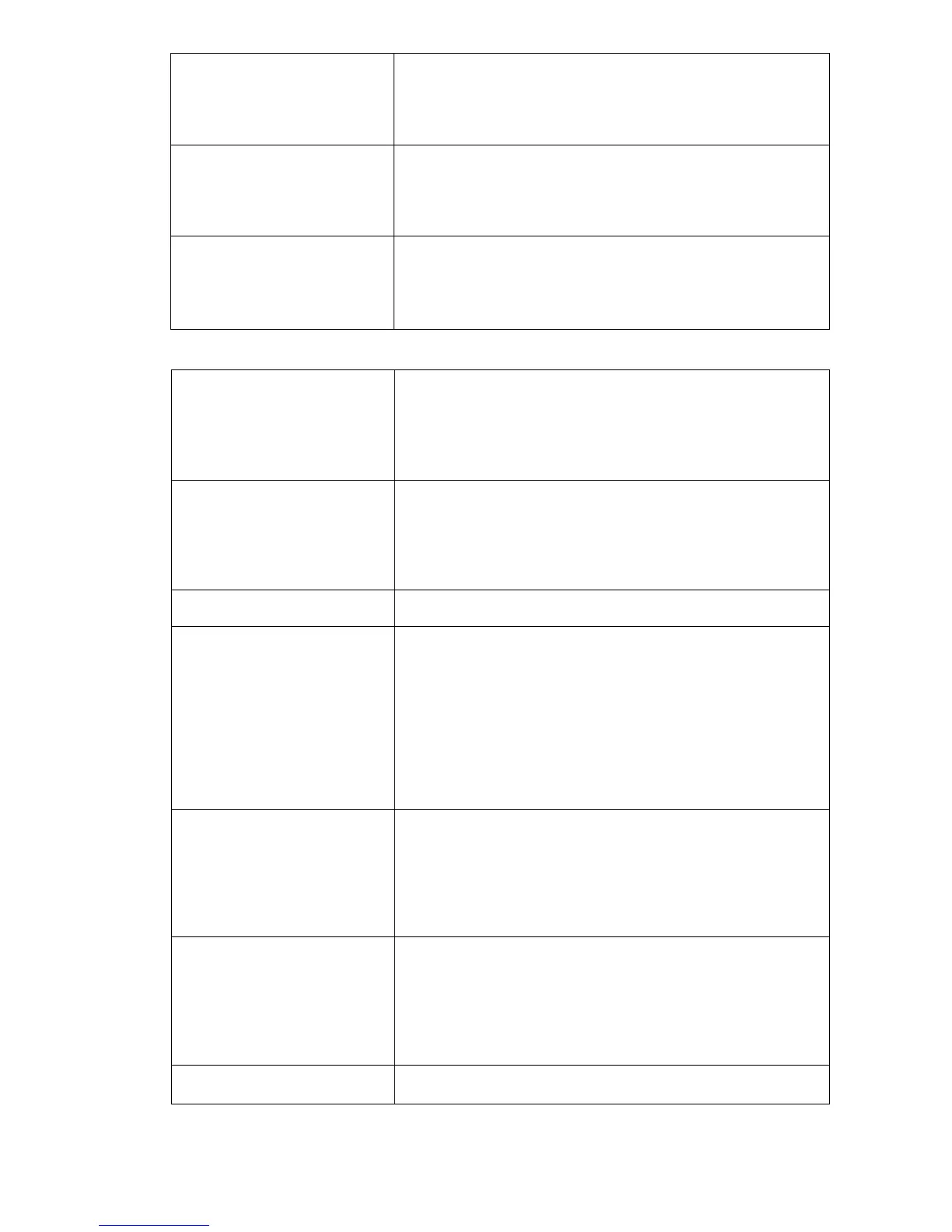

Boiler cooling temperature

Temperature of boiler cooling off. Above this temperature the controller

activates HUW pump and opens mixer cycles to allow boiler cooling off.

The controller activates HUW pump if this temperature exceeds

maximum value. The controller will not open mixer cycle when mixer

setting = floor active

Parameter B FuzzyLogic

Parameter C FuzzyLogic

Applicable to FuzzyLogic mode. It has an impact on the time necessary

for the boiler to reach the preset value and the stability of the boiler

temperature. It is not recommended to modify the parameters if the

adjustment time and the stability of the preset temperature are as

required.

NO (CH boiler pump is not activated when room thermostat starts

operation),

YES (CH boiler pump is deactivated when room thermostat starts

operating)

CH activation temperature

Parameters determines the temperature at which CH boiler pump is

activated. It protects the boiler against watering due to cooling off with

cold water returning from installation. Attention: Deactivating boiler pump

only does not guarantee boiler protection against watering and

consequently corrosion. Additional automatics should be used, i.e. 4 way

valve or 3 way thermostatic valve.

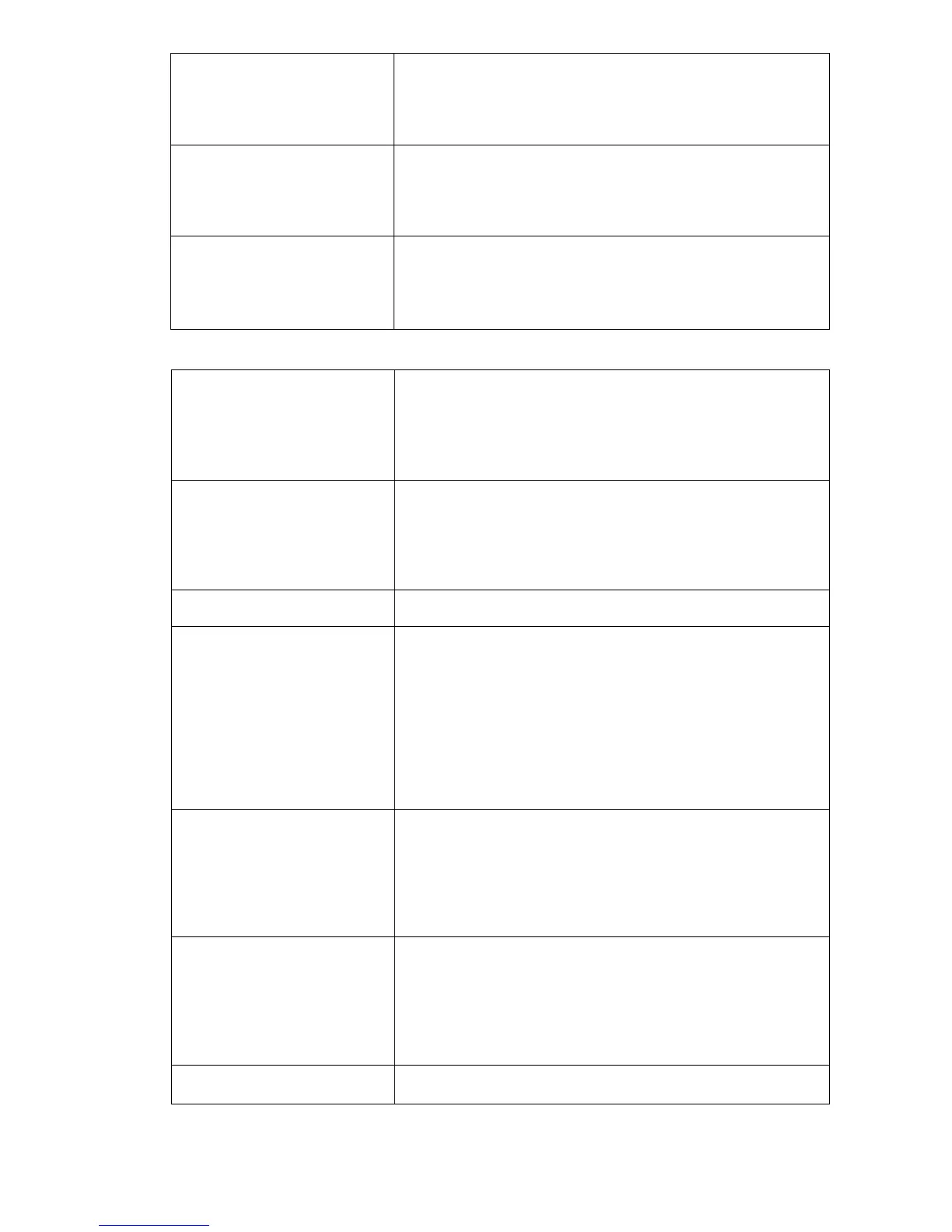

CH pause when HUW loading*

Available after connecting HUW sensor. Prolonged feeding of HUW silo

during priority HUW deactivated may cause to overcooling of the CH

installation, because CH pump is deactivated. Parameter CH pump

pause during feeding HUW prevents against periodical activating CH

pump during feeding HUW silo. CH pump after this time will activate on

constant, programmed time of 30s.

Available after CH sensor connecting. It is a parameter by which it can

be reduced setting too low preset HUW temperature.

Available after connecting HUW sensor. Parameter determines to what

maximum temperature HUW silo will be heated during cooling the boiler

in alarm situations. It is a very important parameter, because setting too

high value of it may cause risk of scalding with HUW. Too low value of

parameter will cause that during boiler overheating it will not be possible

to cool off the boiler to the HUW silo. During design of HUW installation,

it is necessary to take into account risk of damaging the controller. Due

to breakdown of the controller water in the silo can heat up to dangerous

temperature. It is necessary to use additional protection in the form of

thermostatic valves.

Boiler Increase by HUW and Mixer

Parameter determines how high the boiler temperature will be increased

to load HUW silo, buffer and mixer cycle. Temperature increase is only

realizing when it is necessary. When preset boiler temperature is at

sufficient level then controller will not change it due to the fact of feeding

the HUW silo, buffer or mixer cycle. Increasing preset boiler temperature

during feeding HUW silo is signaled with letter “C” in main window of

displayer

Prolonging of HUW operation*

Available after connecting HUW sensor. After feeding HUW silo and

deactivating HUW pump may be a risk of boiler overheating. It happens

in case when preset HUW temperature was higher than boiler preset

temperature. This issue is exceptionally important in HUW pump

operation in SUMMER mode, when pump is deactivated. To cool off the

boiler HUW pump operation can be prolonged by HUW operation time

prolongation.

Circulation standstill time

Pausing time between periods of circulation pump operation is defined

with value of parameter Circulation stop time (recommended setting 15-

Loading...

Loading...