2018-07

30

LB Remote I/O System

Installation

X2 Terminal Assignment

X2.1 = 0 V

X2.2 = + 24 VDC (SELV/PELV)

X2.3 = earth

X1 Terminal Assignment

X1.1 = 0 V

X1.2 = + 24 VDC (SELV/PELV)

X1.3 = earth

3.3.3 LB9035A

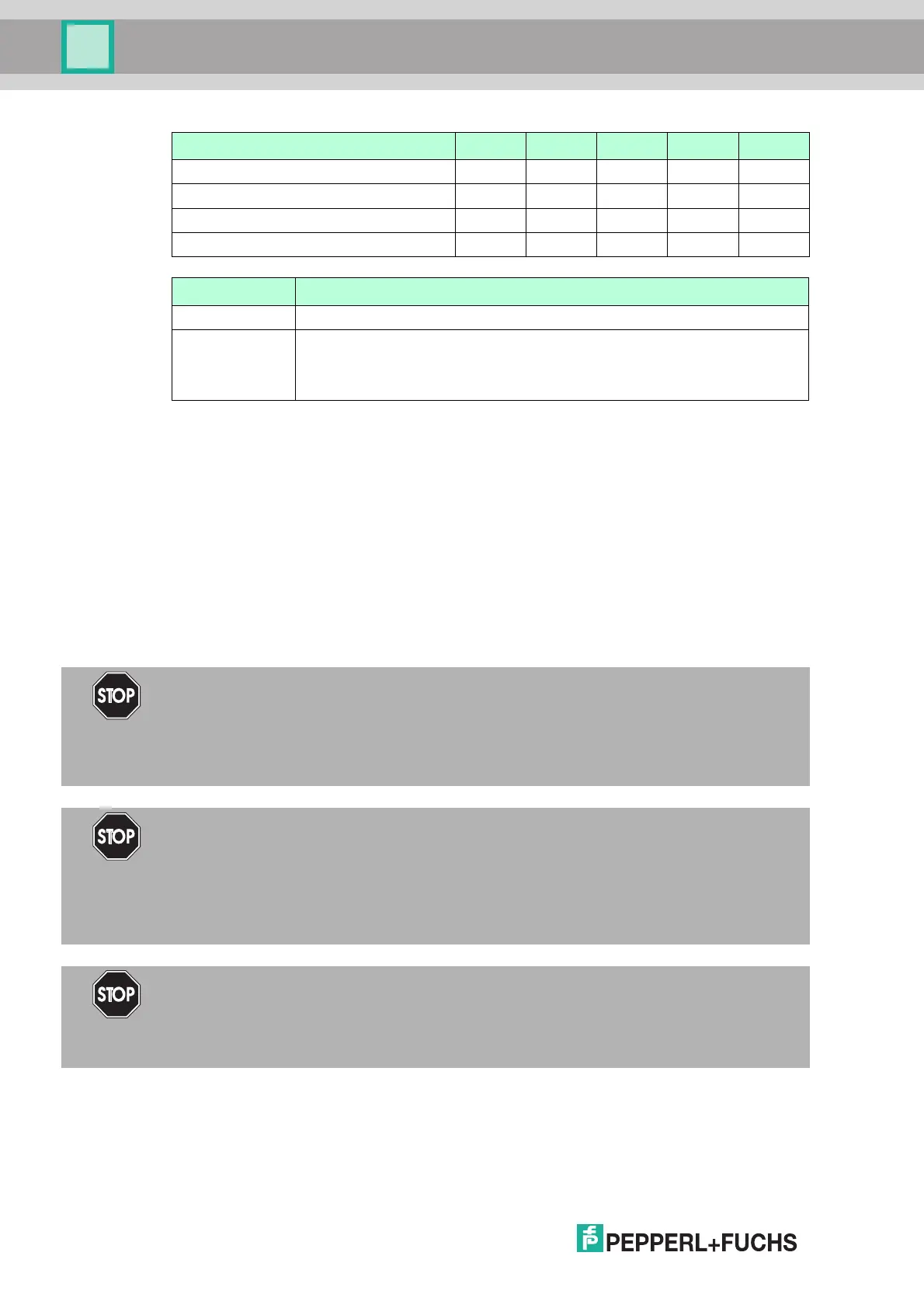

Bereich 1 2 3 4 5

Steckplätze LB9022S 3...5 6 ... 10 11 ... 15 16 ... 20 21 ... 24

Steckplätze LB9024S 25 ... 29 30 ... 34 35 ... 39 40 ... 44 45 ... 48

S1-Schalter S1.1 S1.2 S1.3 S1.4 S1.5

X3-Kontakt X3.1 X3.2 X3.3 X3.4 X3.5

S1.1 ... S1.5 Auswirkung

S1.x = ON Die Abschaltung der E/A-Module im zugehörigen Bereich ist deaktiviert.

S1.x = OFF Die Abschaltung wird im zugehörigen Bereich durch den zugehörigen X3-

Kontakt gesteuert. Wenn der X3-Kontakt offen ist (X3.x = OFF), werden die

E/A-Module mit Abschalteingang für den zugehörigen Bereich

abgeschaltet.

Danger!

Risk of explosion

Accessories such as plugs and terminators that do not meet the requirements for use in

hazardous areas can cause explosive mixtures to ignite.

Only use accessories approved for use in the respective environment.

Danger!

Risk of Explosion

Connecting and disconnecting from circuits such as terminals, plug-in jumpers or terminators

can ignite potentially explosive mixtures.

Connecting and disconnecting from circuits is permitted only when not located in a potentially

explosive atmosphere.

Danger!

Risk of Explosion

Actuating the operating elements can ignite potentially explosive mixtures.

Only actuate the operating elements when not located in a potentially explosive atmosphere.

Loading...

Loading...