N39453 Chapter 4

Page 81

Atomiser maintenance

Atomiser faults

Caution: A faulty atomiser must be renewed by a person who has had the correct training.

Regular maintenance of the atomisers is not necessary. The atomiser nozzles should be renewed and not

cleaned, and renewed only if an atomiser fault occurs. Some of the problems that may indicate that new

nozzles are needed are listed below:

• Engine will not start or is difcult to start

• Not enough power

• Engine misres or runs erratically

• High fuel consumption

• Black exhaust smoke

• Engine knocks or vibrates excessively

• Excessive engine temperature.

Warnings!

• If your skin comes into contact with high-pressure fuel, obtain medical assistance immediately.

• Keep away from moving parts during engine operation. Some moving parts cannot be seen clearly while

the engine runs.

Remove all the atomisers and have them tested by a specialist.

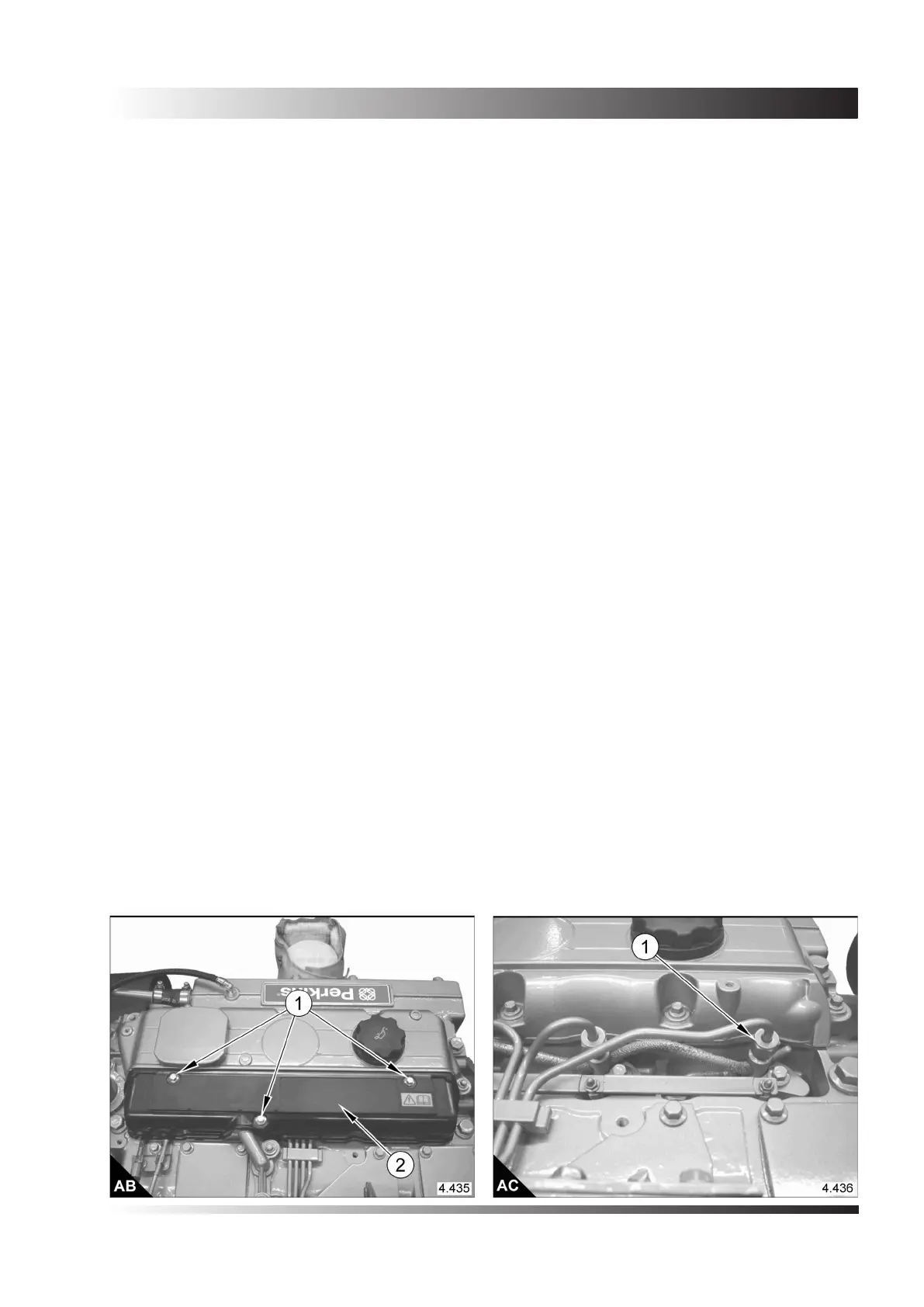

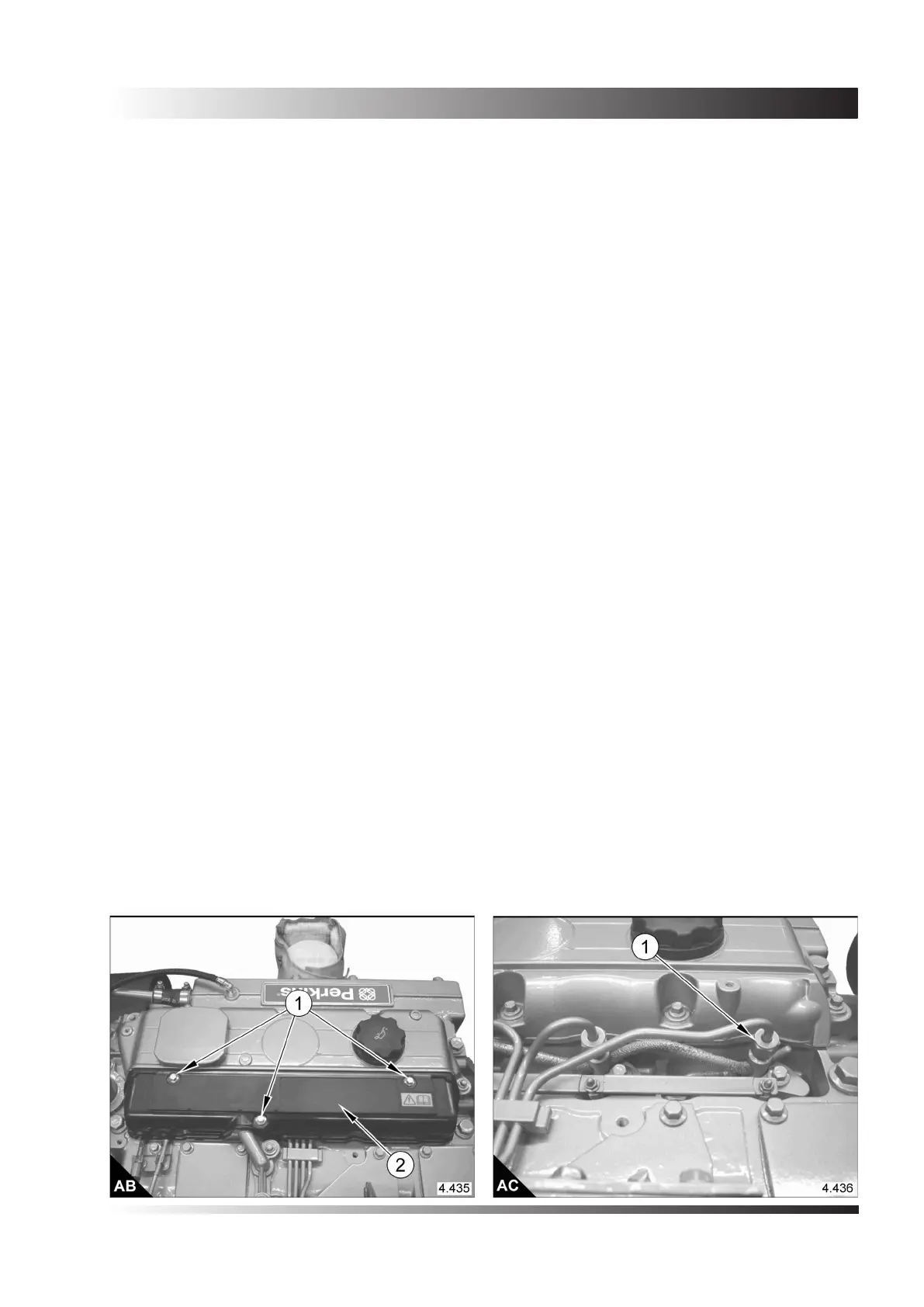

Remove the atomiser cover setscrews (AB1) and remove the atomiser cover (AB2). In order to nd which

atomiser is defective, operate the engine . Loosen and tighten the union nuts (AC1) of the high-pressure fuel

pipe at each atomiser. Do not loosen the union nut more than half a turn. When the union nut of the defective

atomiser is released, it has little or no effect on the engine speed.

Loading...

Loading...