BG 5171 BEN / B (2017-02) PBR 260.oi 23

Replacement is necessary, when

• the sensor is severely contaminated

• the sensor is faulty, e.g. filament broken.

Gauge failures due to contamination or wear and tear, as well as

expendable parts (e.g. filament), are not covered by the warranty.

• Allen wrench AF 2.5

• Spare sensor (→ 26)

a) Deinstall the gauge (→ 24).

b) Remove the electronics unit from the faulty sensor and mount it on the new

sensor (→ 10).

c) Mount the gauge (→ 9).

d) Adjust the gauge (→ 19).

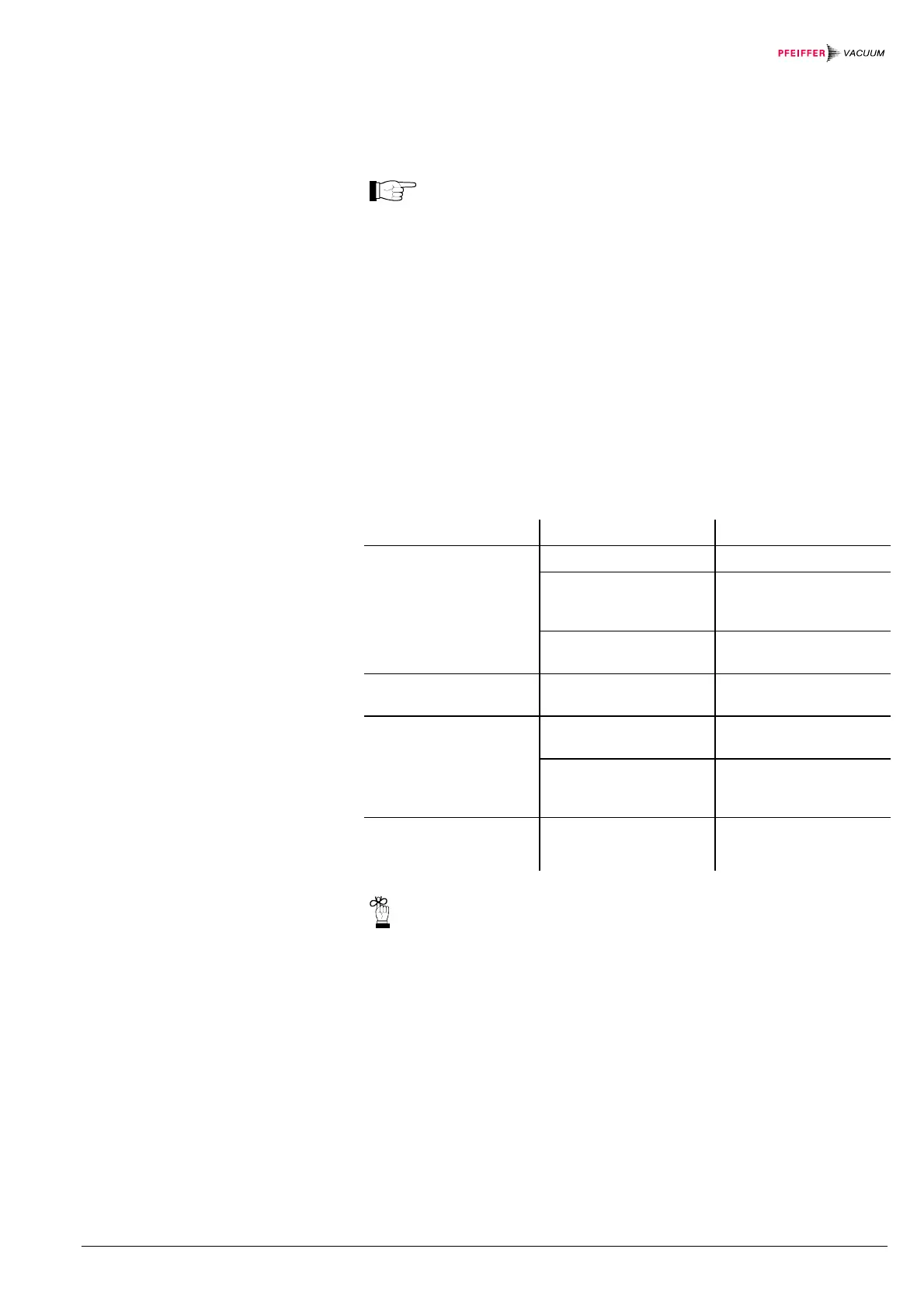

Problem Possible cause Correction

No measuring signal No supply voltage Turn on the power supply

Connection cable defec-

tive or not correctly

plugged in

Check connection cable

Gauge in an undefined

condition

Turn gauge off and on

again (reset)

Measuring signal 0.3 V Hot cathode error

(sensor faulty)

Replace sensor (→ 23)

Measuring signal 0.5 V Pirani error

(sensor faulty)

Replace sensor (→ 23)

Electronics unit not

correctly mounted on

sensor

Check connection

Gauge does not switch

over to BA at low pres-

sures

Pirani zero point out of

tolerance

Carry out a zero point

adjustment (→ 19)

In case of an error, it may be helpful to first turn the voltage supply off and

on again after 5 s.

5.6 Replacing the Sensor

Tools / material required

Procedure

5.7 What to Do in Case of

Problems

Loading...

Loading...