11 - 8

Cooling

System seal control

- Check adequate seal of the circuit when it is under pressure and heated;

- For a more complete control wait until the system has cooled because small leaks, invisible due to evaporation

phenomena, may occur;

- The water pump has a drainage hole for any leaks resulting from mechanical seal of the cooling system or of the

oil seal from the spindle seal;

- On discovery of coolant or oil leaks, proceed with overhaul of the pump (see Chapter 5-FLYWHEEL COVER).

N.B.: During repairs on the cooling system, do not use grease or oils. Failure to respect this regulation causes

permanent deformation of the gasket seals.

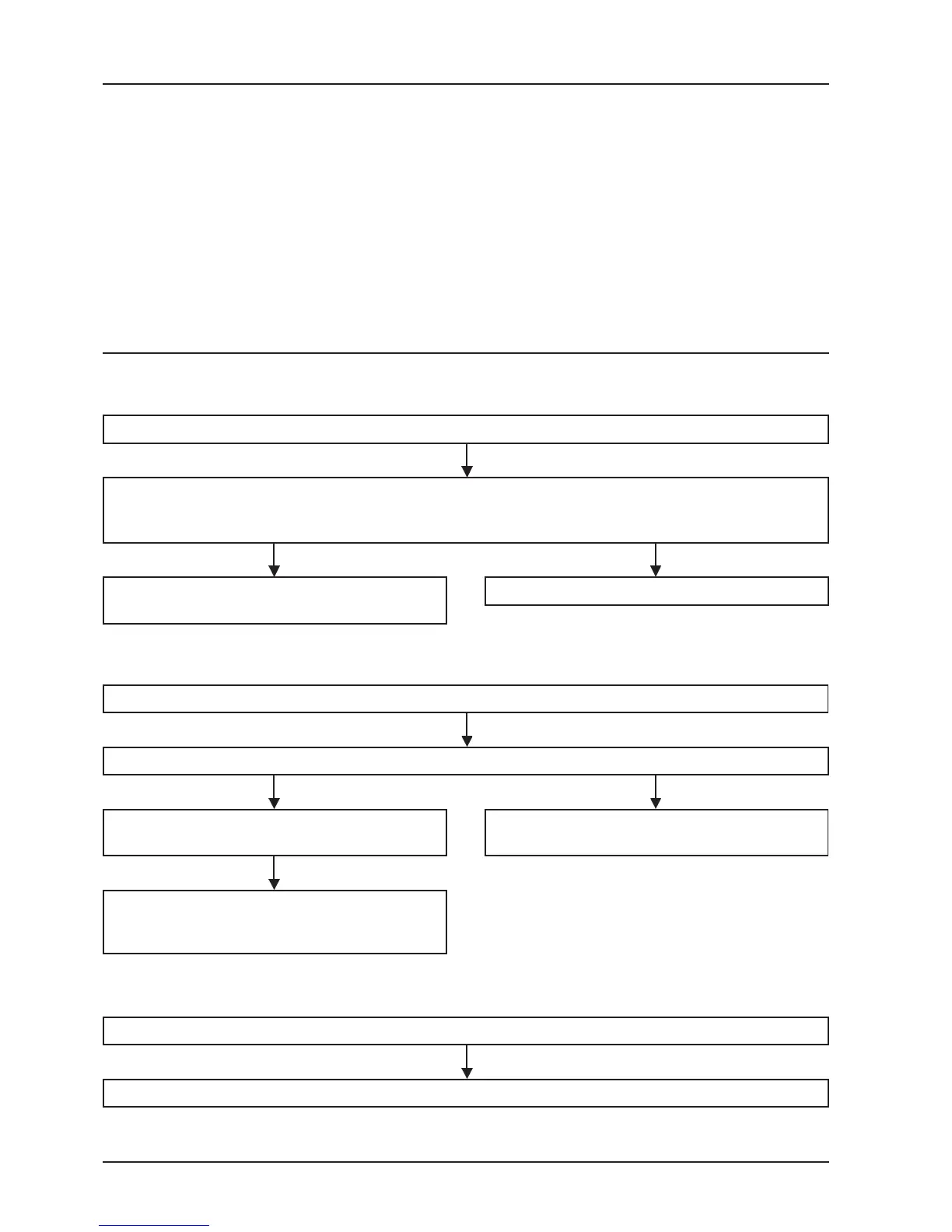

Diagnostics guide

Eccessive system pressure

Check condition of the expansion tank plug.

N.B.: The plug has an overpressure valve calibrated to 0.9 bar.

There is also the valve which must allow entry of air during the cooling phase.

Check gasket seal of the head (see Chapter 7-

THERMAL UNIT AND TIMING SYSTEM)

Replace the plug.

NOYES

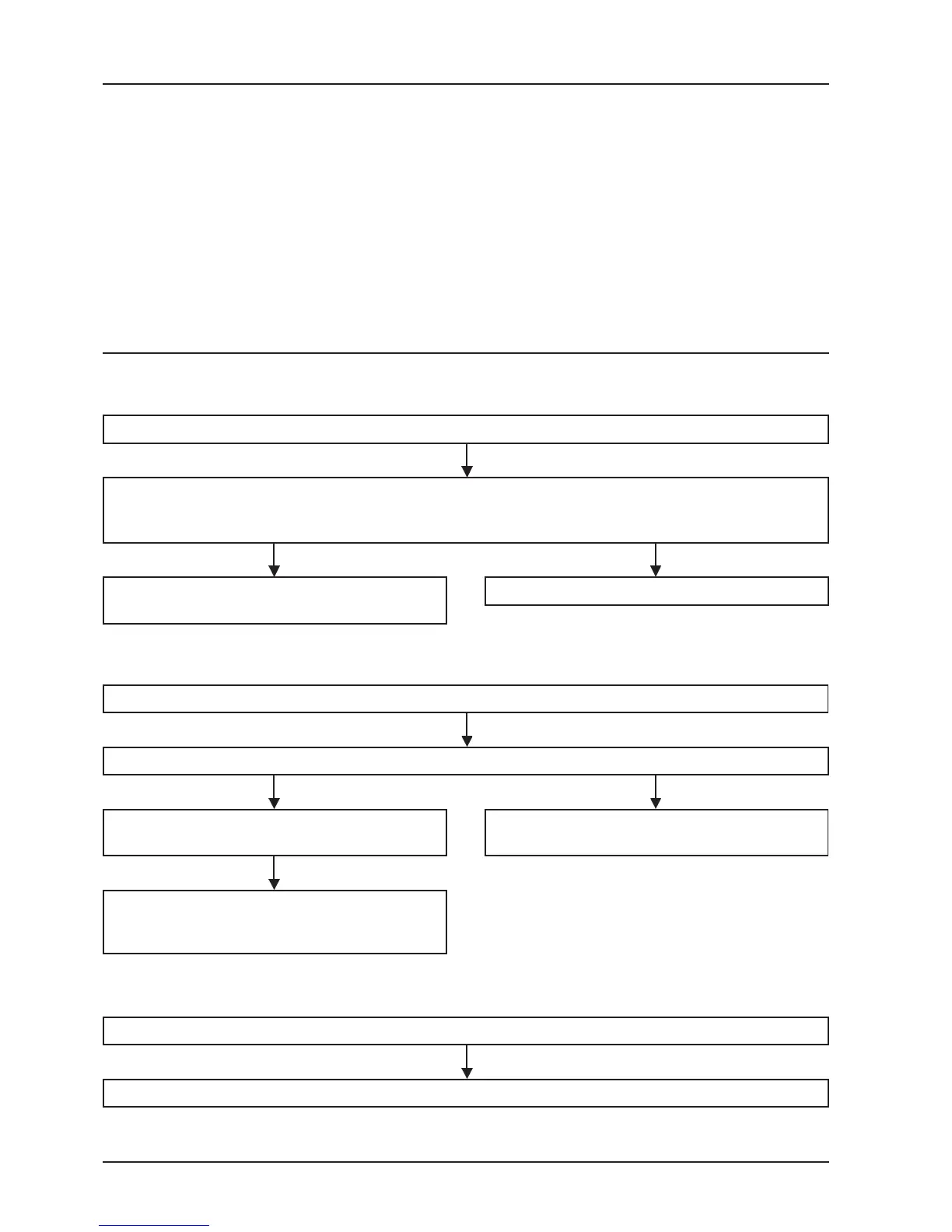

Coolant consumption

Check external seals of the system as described previously.

Check gasket seal of the head (see Chapter 7-

THERMAL UNIT AND TIMING SYSTEM)

Proceed to repair of the damaged seals.

NOYES

On discovering water leaking into

the engine oil, check

the head cooling circuit pad.

Presence of oil in the coolant.

Check of the head gasket seal (see Chapter 7-THERMAL UNIT AND TIMING SYSTEM)

Loading...

Loading...