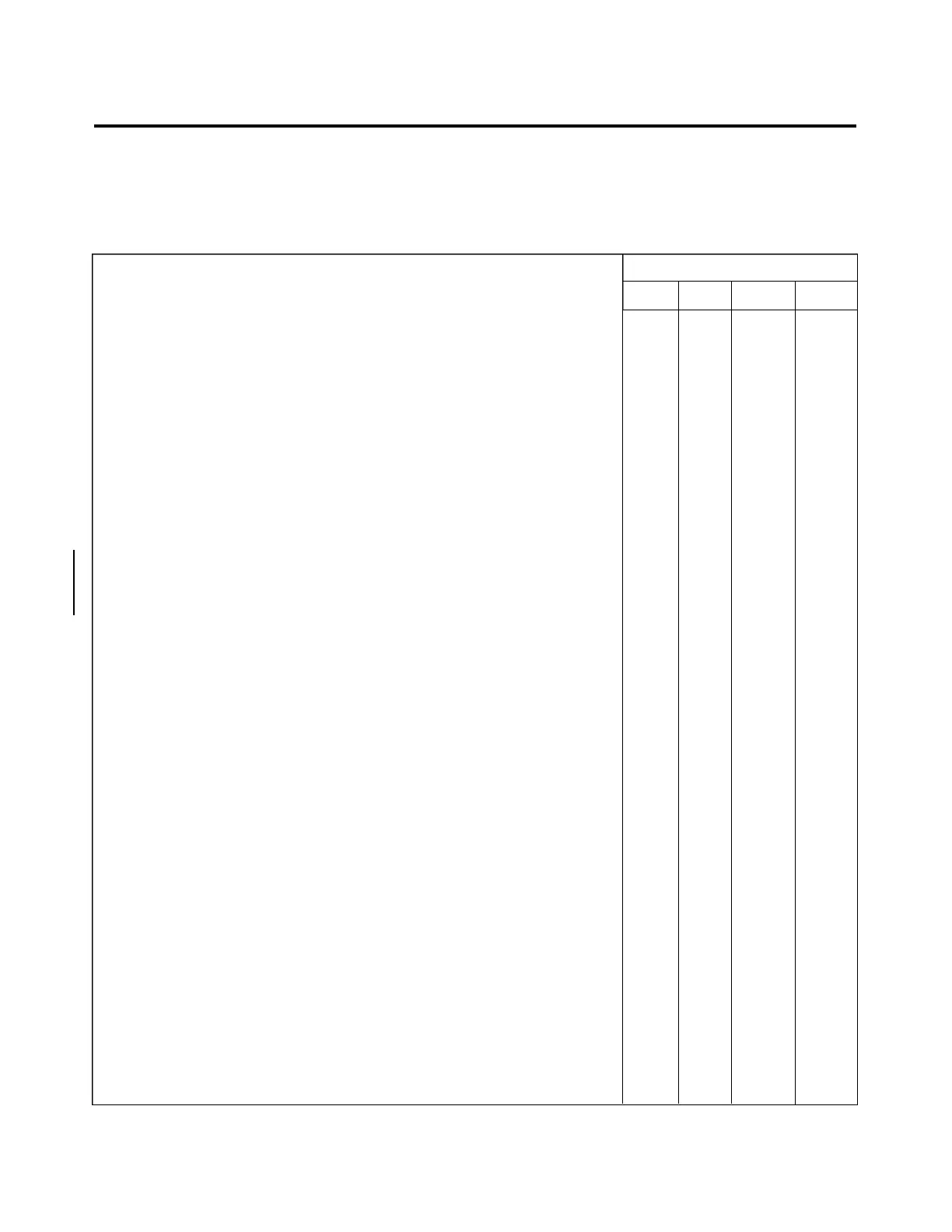

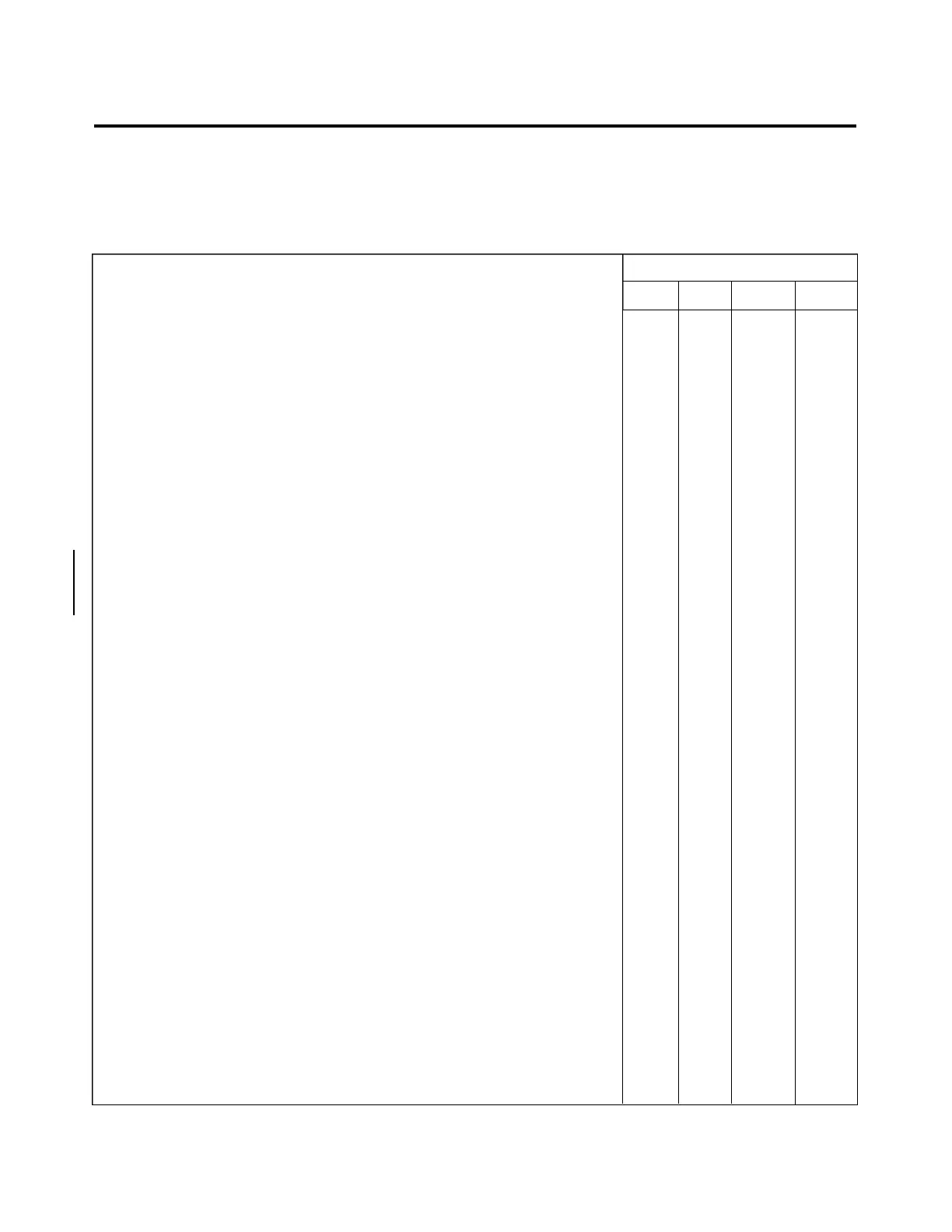

PERIODIC INSPECTIONS. (cont)

—NOTE—

Perform all inspections or operations at each of the inspection

intervals as indicated by a circle (O). (See Notes 1, 2 and 3.)

B. ENGINE GROUP (CONTINENTAL) (cont)

7. Clean and inspect oil radiator cooling fins.......................................... O O O

8. Fill engine with oil per information on cowl or lubrication chart....... O O O

9. Clean engine........................................................................................ O O O

CAUTION: Use caution not to contaminate pressure pump with

cleaning fluid.

10. Inspect condition of spark plugs (Clean and adjust gap as required)

(See Note 10) ...................................................................................... O O O

11. Check cylinder compression (See Note 14)........................................ O O O

12. Inspect ignition harness and insulators (high tension leakage and .....

continuity) (See Note 7 and 23).......................................................... O O O O

13. Check magneto points for proper clearance (Maintain clearance at

.018 ± .006) (See Note 7).................................................................... O O O

14. Inspect magneto for oil seal leakage................................................... O O O

15. Inspect breaker felts for proper lubrication......................................... O O O

16. Inspect distributor block for cracks, burned areas or corrosion, and

height of contact springs..................................................................... O O

17. Inspect magnetos to engine timing (See Note 17) .............................. O O O

18. Overhaul or replace magnetos (See Note 7)

19. Remove induction air filter and tap gently to remove dirt particles

(Replace as required) .......................................................................... O O O O

20. Clean injector nozzles as required (Clean with acetone only)............ O O O O

21. Inspect induction airbox valve and check for excessive wear or

cracks, replace defective parts ............................................................ O O O

22. Inspect fuel injector attachments for loose hardware.......................... O O O

23. Inspect intake seals for leaks and clamps for tightness....................... O O O

24. Inspect all air inlet duct hoses (Replace as required).......................... O O O

25. Inspect condition of flexible fuel lines................................................ O O O

26. Replace flexible fuel lines (See Note 7).............................................. O

27. Clean gascolator bowl and screen....................................................... O O O O

28. Inspect fuel system for leaks............................................................... O O O

29. Inspect condition and operation of fuel pumps (engine driven and

electric) ............................................................................................... O O O

30. Overhaul or replace fuel pumps (engine driven and electric)

(See Note 7)

31. Inspect pressure pump and lines......................................................... O O O

5-20-01

Page 5-03

Revised: August 8, 1984

1B2

PIPER AIRCRAFT

PA-28RT-201 / 201T

MAINTENANCE MANUAL

Inspection Time (hrs)

50 100 500 1000

Nature of Inspection

Loading...

Loading...