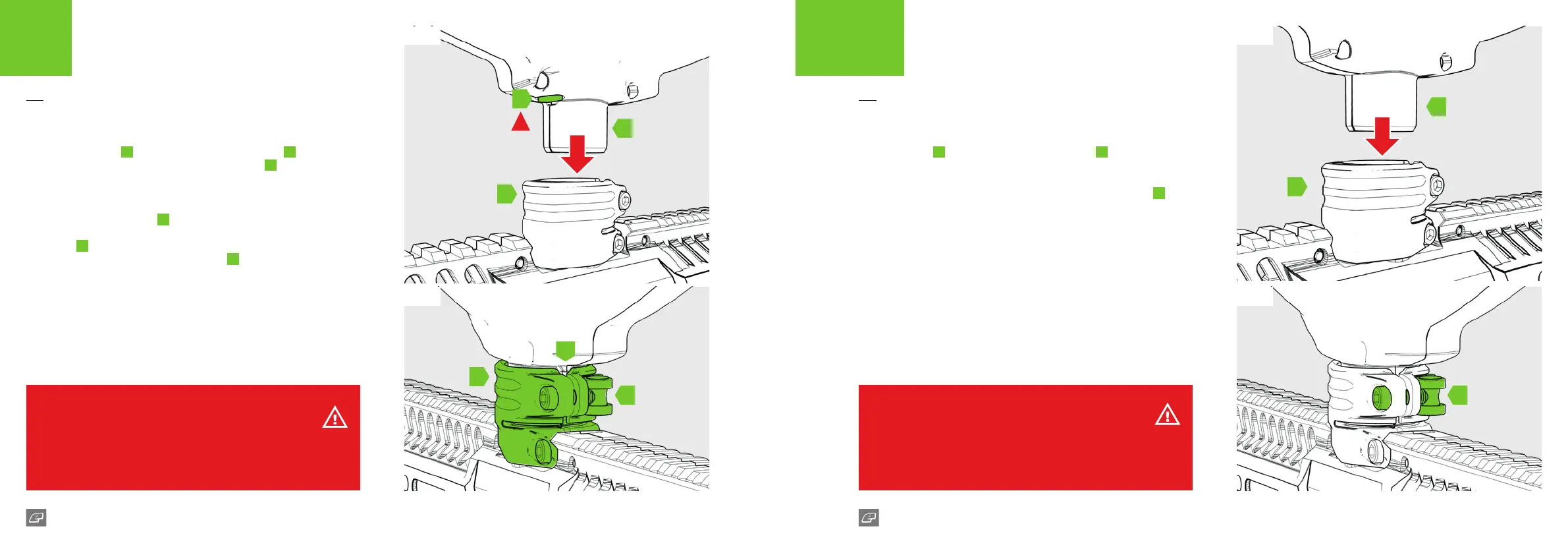

FIG-1

Push the PAL loader

A

into the PAL feedneck assembly

B

as per any

other loader. Ensure the PAL agitation plate actuator

C

aligns with the

PAL plunger in the front of the PAL feedneck assembly to work correctly.

FIG-2

The PAL feedneck assembly

B

has a recess in the rear to assist with

alignment of the PAL loader. When tting the PAL loader make sure

the dimple

D

sits centrally within the recess. If the PAL loader doesn’t

t correctly use the clamping feedneck lever

E

to loosen / tighten

accordingly.

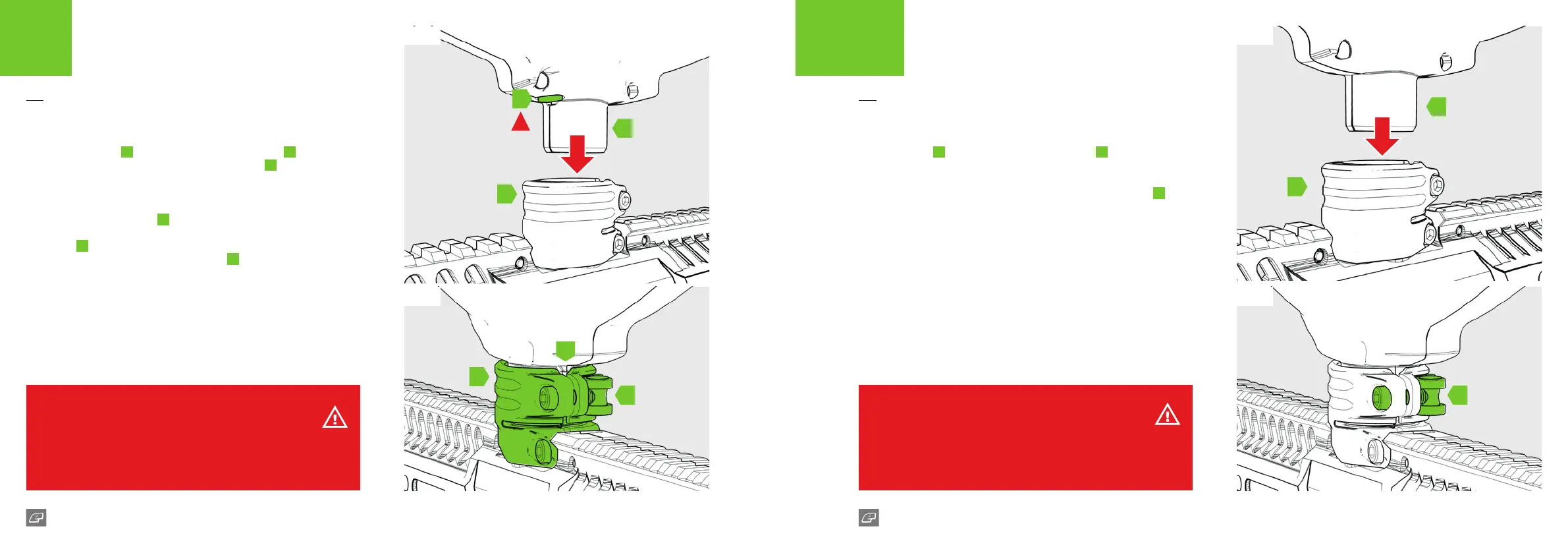

FIG-1

Push the loader

A

into the PAL feedneck assembly

B

as normal.

FIG-2

If the loader doesn’t t correctly use the clamping feedneck lever

E

to

loosen / tighten accordingly.

WARNING!

If the agitator plate actuator isn’t aligned with the PAL plunger then the PAL

system may not work correctly.

Always make sure the marker is set to SAFE when installing a loader.

NOTICE!

Although the PAL plunger will still activate when red, NO gas is wasted nor is

the eciency of the marker aected in any way.

The PAL system WILL NOT improve the performance of non-PAL gravity-fed

loaders nor will it aect the performance of any force-fed loaders.

FIG-1 FIG-1

FIG-2 FIG-2

A

A

E E

B

B

B

C

D

!

18 19

EMF100 EMF100

QUICK START

ATTACHING A PAL

LOADER SYSTEM

QUICK START

ATTACHING A

GENERIC LOADER

Loading...

Loading...