32 33

EMF100 EMF100

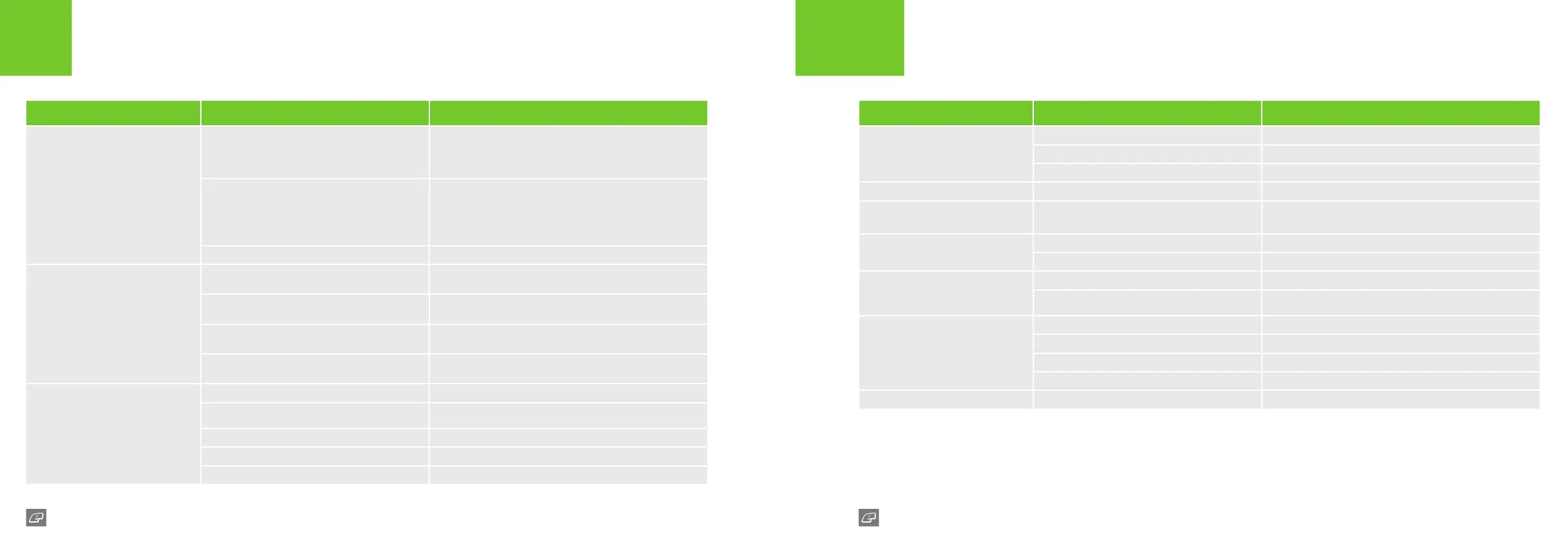

MAINTENANCE

FAULT FINDING TABLES

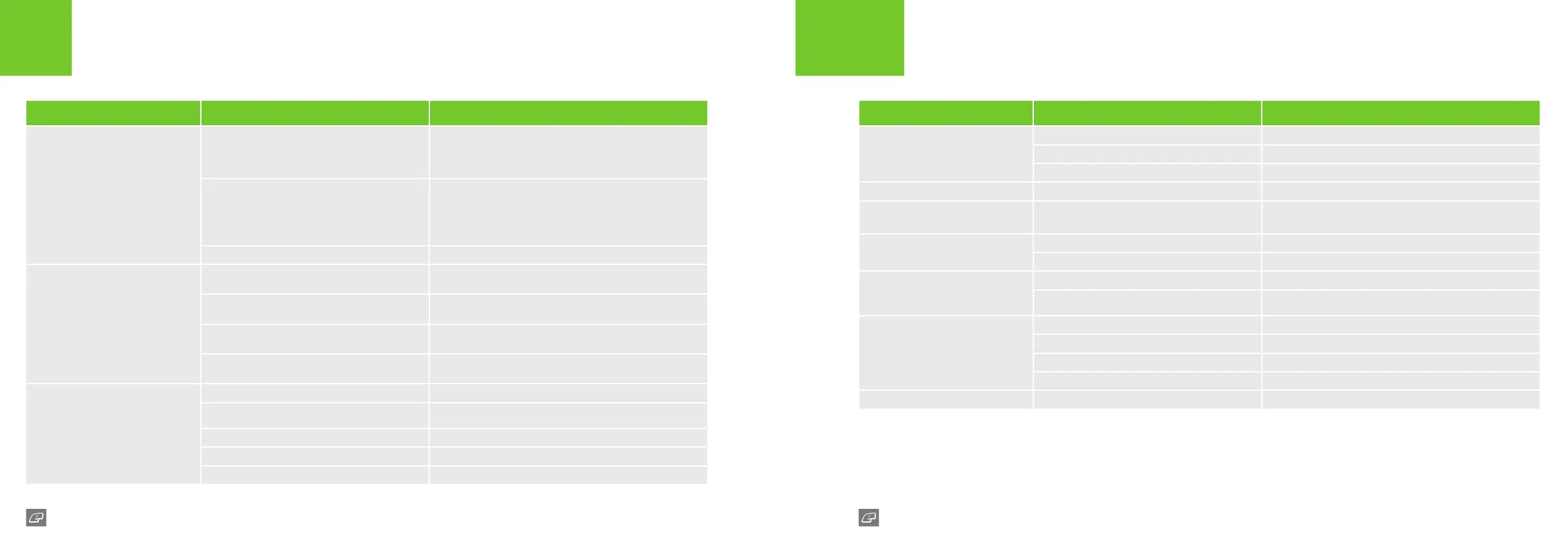

MAINTENANCE

FAULT FINDING TABLES

SYMPTOM POSSIBLE CAUSE SOLUTION

The EMF100 leaks from the three-way.

The gasket between the three-way body and gun

body, o-ring on air transfer pipe or the gasket under

the three-way plate are damaged or dirty.

Ensure the gasket is seated correctly.

Replace the gaskets if damaged using EMF100 parts kit.

Check condition of the air transfer pipe 010 NBR70 o-ring.

The three-way is over-pressurised.

Check the output pressure of the inline regulator

and adjust accordingly.

Clean and inspect the inline regulator assembly paying particular

attention to the piston tip and regulator seal.

Replace damaged components as necessary.

Damaged or incorrect seals on the three-way spool. Replace and/or lubricate three-way spool seals.

The EMF100 leaks down the barrel.

Dirty or damaged can o-rings.

Clean and lubricate or replace 020 NBR70 and

017 NBR o-rings on the front of the can.

Dirty or damaged o-rings on the spool.

Clean and lubricate or replace the 011 NBR70 and

012 NBR70 o-rings on the main spool.

Dirty or damaged bolt o-rings.

Clean and lubricate or replace 14x2 NBR70 o-ring

on the back of the bolt.

Dirty or damaged rear bolt guide o-ring.

Clean and lubricate or replace 14x2 NBR70 o-ring

towards the back of the bolt guide.

The marker is breaking paintballs

in the barrel or breech.

The ball detents are damaged or missing. Replace the ball detents.

The force setting of the loader is too high

(where applicable).

Reduce the loader force feed setting.

The paint is poor quality. Try a higher grade of paint.

The velocity is set too high. Check and adjust the velocity of the EMF100.

The magazine requires maintenance. Disassemble and clean the magazine. Replace if necessary.

SYMPTOM POSSIBLE CAUSE SOLUTION

The EMF100 does not re.

The air system is not fully engaged. Screw in the air system until it fully engages.

The POPS bonnet is not engaged. Make sure the POPS bonnet is pushed towards the POPS body.

The three-way is damaged. Replace the three-way.

Low constant velocity. The inline regulator output pressure set too low. Increase the output pressure of the inline regulator.

High velocity rst shot. The inline regulator pressure is creeping.

Strip and clean the inline regulator replacing the regulator

seal inside the regulator adjuster assembly.

Velocity drop-off during rapid re.

Air system regulator does not have high enough ow. Try another air system.

Dirty/partially blocked inline regulator. Strip, clean, lubricate and rebuild the inline regulator.

Two or more balls are being

fed into the breech.

Worn, damaged or missing ball detents. Change the rubber ball detent.

The feed force is too high from loader.

(where applicable).

Adjust loader settings/use lower force loader.

EMF100 is inconsistent.

The inline regulator is dirty. Strip and clean inline regulator, replace regulator seal.

Poor quality paintballs. Use better quality paintballs.

Poor paintball size to barrel bore match. Use a closer paintball to barrel bore size.

Inconsistent air supply from air system. Service the air system.

EMF100 is inefcient. Poor paintball size to barrel bore match. Use a closer paintball to barrel bore size.

If an issue with the marker cannot be solved using the fault nding guide, contact your nearest Eclipse Service Centre for assistance.

Loading...

Loading...