ENGINE

3.35

2871043

A

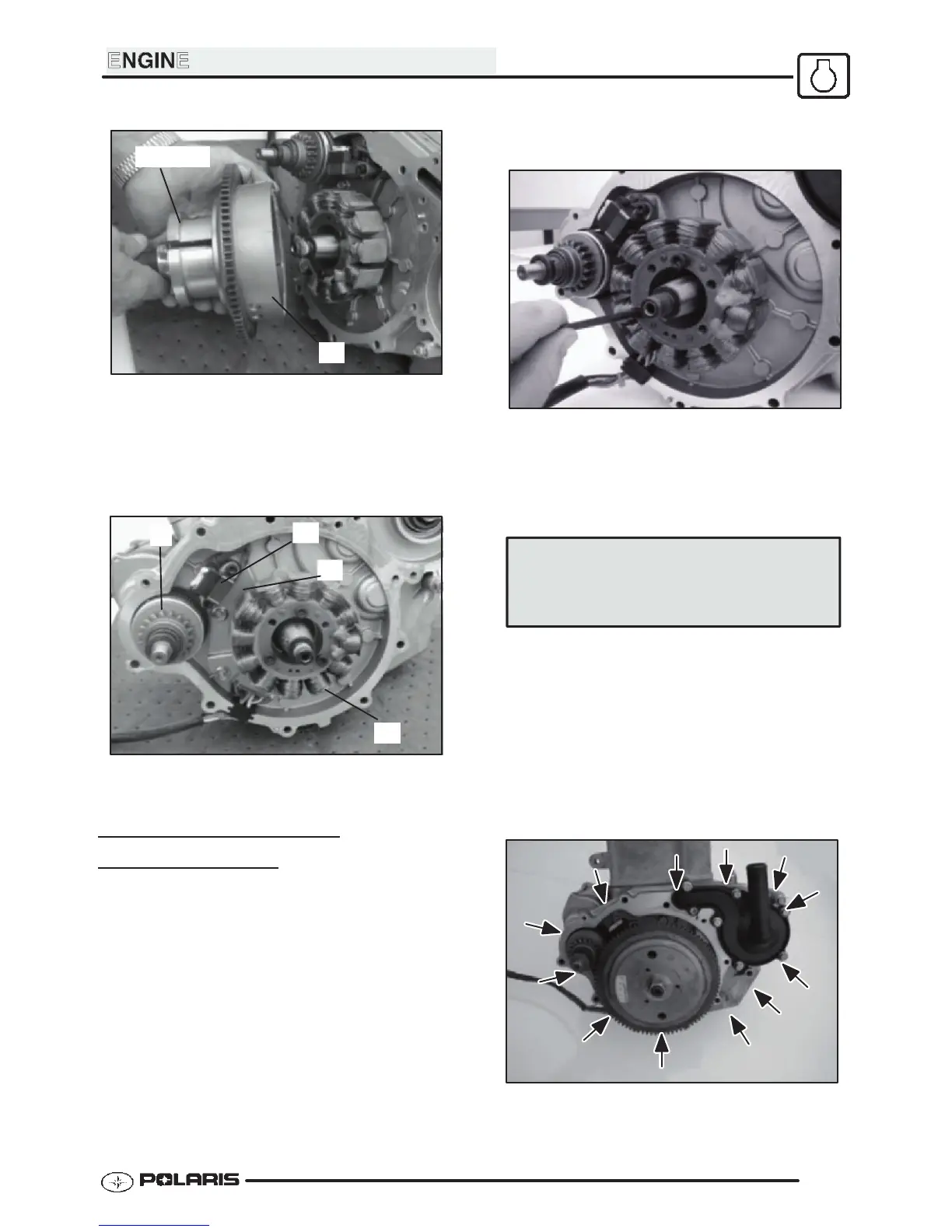

4. Use caution when removing the wire holddown

(B), trigger coil (C), and the stator assembly (D).

Do not tap or bump the gear /stator housing

cover or the stator. This could cause the seal

around the gear/stator housing cover and the

crankcase to break, causing a leak.

D

C

E

B

5. Remove the bendix (E) if necessary.

FLYWHEEL/STATOR

INSTALLA

TION

NOTE: Before assembly, clean the bolts and bolt

holes with Primer N (PN 2870585) to remove any

debris. This will ensure proper sealing when installing

bolts and new Loctitet.

1. Carefully install the stator and trigger coil to the

gear/stator housing cover. Do not tap on the

stator or the gear stator housing cover. This

may cause a leak in between the gear/stator

housing cover and the crankcase.

2. Properly place the stator wires under the wire

holddown and install the bolts. Apply

LocTitet242 (PN 2871949) onto the bolts.

Inspect the bolts, if new bolts are needed, replace

them with new bolts. The new bolts contain patch

lock, so Loctitet is not needed on the new bolts.

Torque bolts to 9--10 ft. lbs. (12--14 Nm).

3. Install the starter bendix if removed.

4. Install woodruff key. Install the flywheel. Install

the flywheel washer and nut. Apply Loctitet 242

(PN 2871949) onto the threads. Torque the

flywheel nut to 80--100 ft.lbs. (109--136 Nm)

Flywheel Nut Torque:

80--100 ft. lbs. (108.50--135.60 Nm)

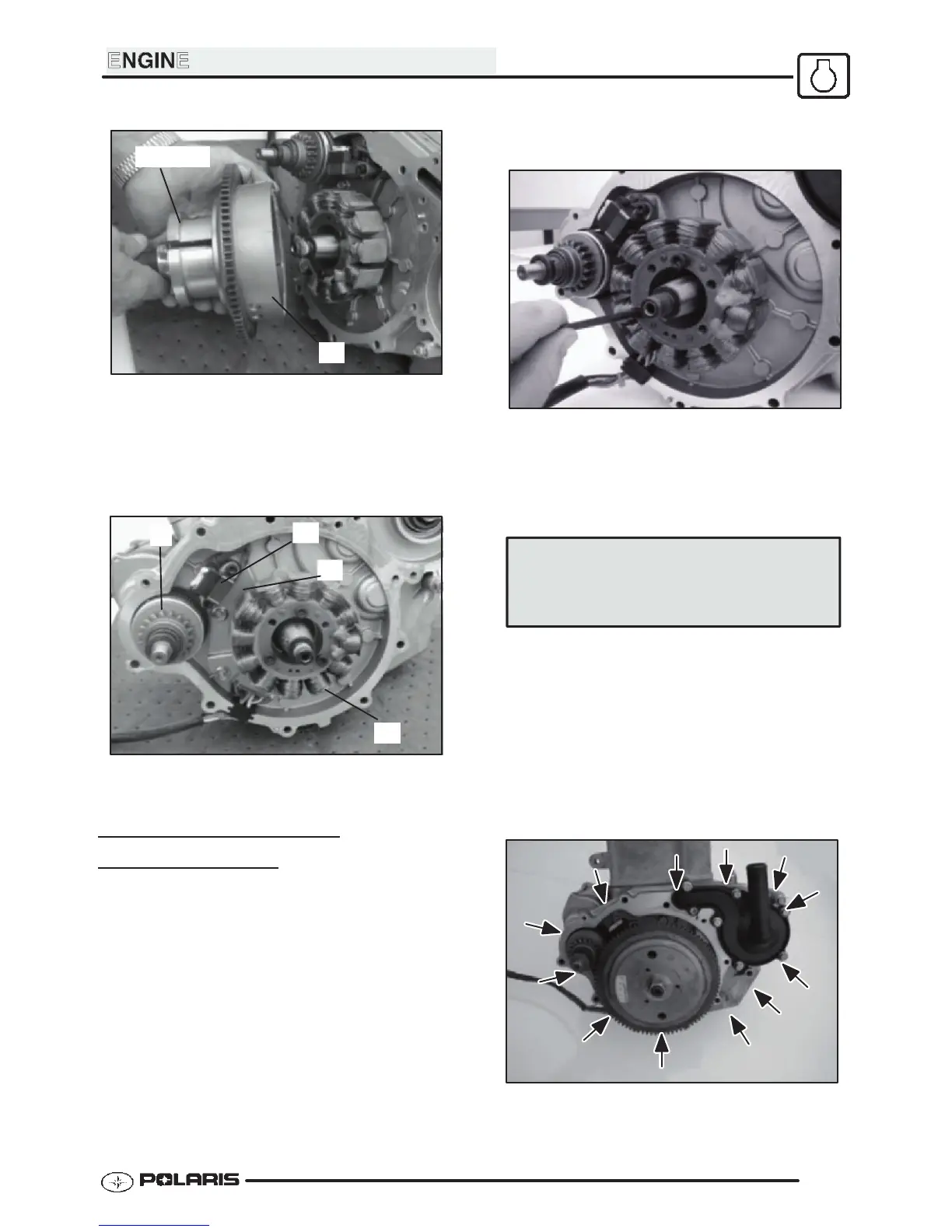

5. Inspect the mating surface around the gear/stator

housing cover and the crankcase for oil seepage.

If there is seepage between the mating surfaces,

then the gear/stator housing cover must be

resealed. Clean the gearcase surfaces and

reseal with a new gasket. Refer to the Lower

Engine Disassembly section and the Lower

Engine Assembly section for details. lnspect the

areas pointed out in the photograph for possible

oil seepage.

FLYWHEEL/STATOR INSTALLATION

6. Install stator housing with new O-rings. Apply

LocTitet271 (PN 2871954) onto the bolts.

Enfocus Software - Customer Support

Loading...

Loading...