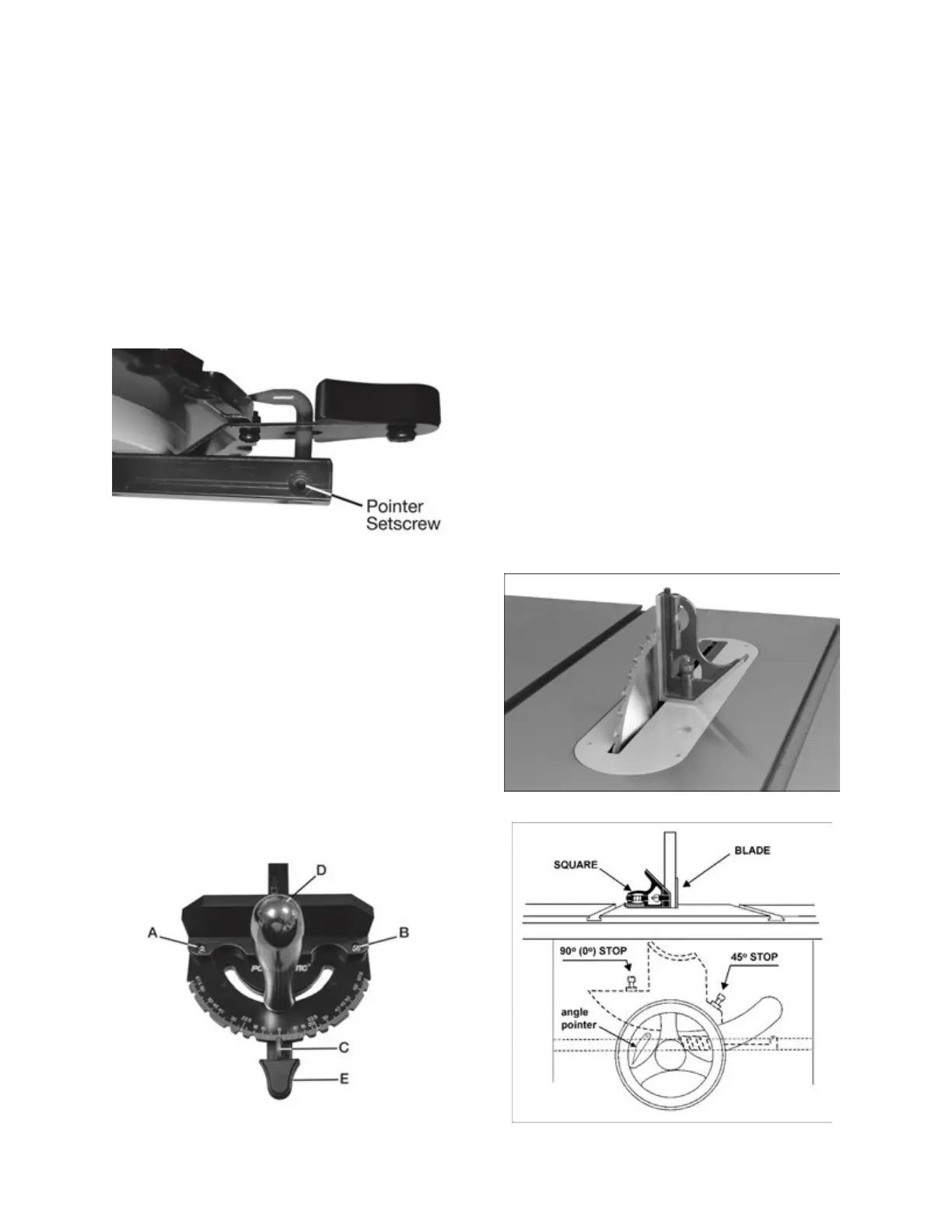

Squaring Miter Gauge (model PM2000BT):

1. Place a square against miter gauge face, and

against flat of blade. (Place square against flat

of blade, not against the teeth which are set

wider than the blade body).

2. Loosen screws A and B as shown in Figure 8-

3C.

3. Adjust the miter gauge fence to make it square

to the blade. Tighten screws A and B.

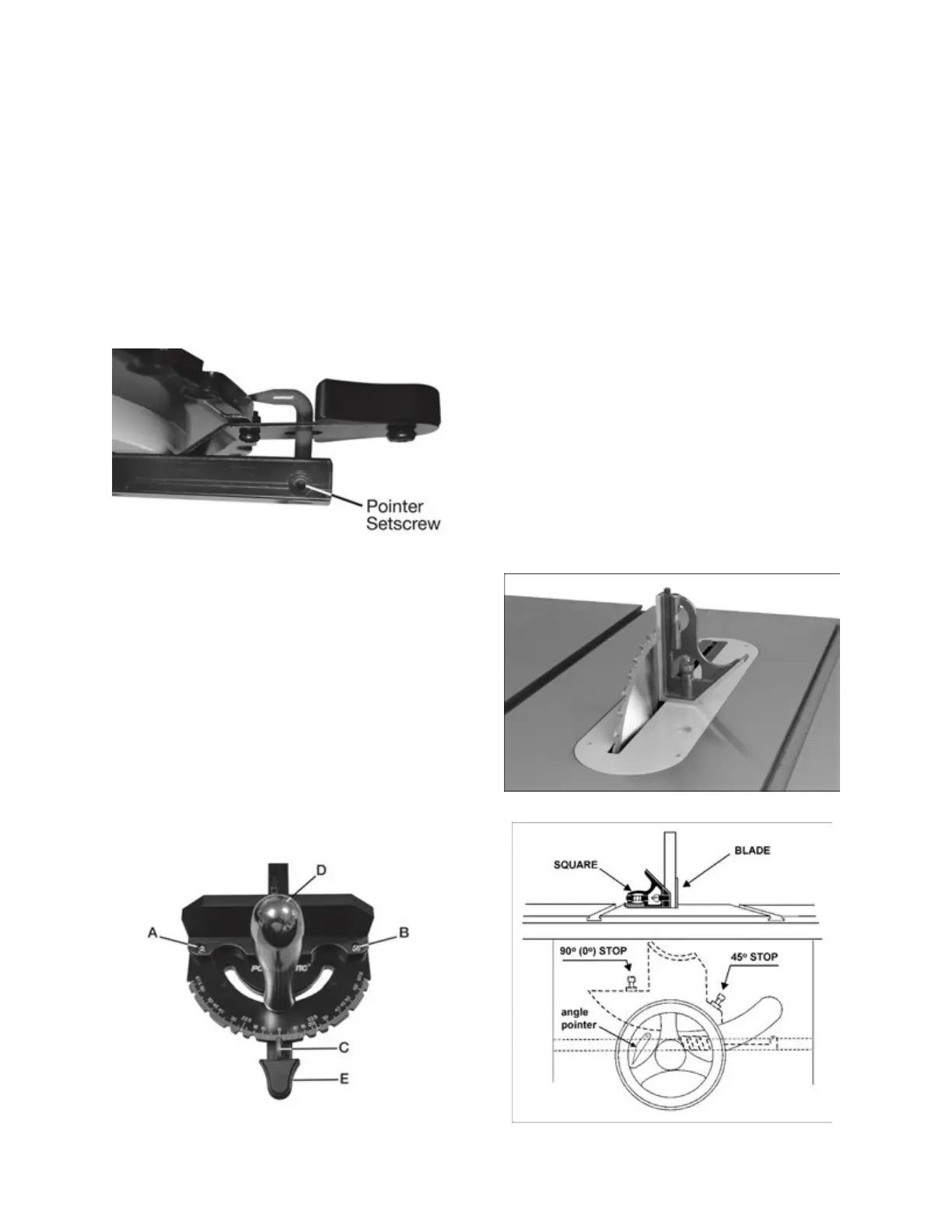

4. After squaring, if the red pointer (C) is not

pointing at 0°, loosen the pointer setscrew (see

Figure 8-3B), rotate the pointer to 0°, and re-

tighten the pointer setscrew.

Figure 8-3B

Adjusting Miter Gauge Angle for

Operations

(model PM2000BT, refer to

Figure 8-3C)

:

1. Unscrew handle (D) just enough to loosen it.

2. Press black tab (E) to release it from stop 0°.

3. Rotate gauge body until red pointer (C) lines up

with desired angle on scale.

4. Tighten handle (D).

5. There are 13 stops at 0°, 15°, 22.5°, 30°, 45°,

60°, and 67.5° left and right. Each of these can

be adjusted to by allowing the spring stop to

lock into each location. Press black tab (E) to

move past each stop location.

Figure 8-3C

8.6 Blade Tilt Stop Adjustment

The stops for 90°, 45° blade tilt, and elevation

settings have all been factory set, and should

require no immediate adjustment. The settings

should be confirmed by the operator, however, and

especially if cuts become inaccurate. Both tilt stops

are located on the trunnion.

8.6.1 Tilt Stop 90°

1. Disconnect machine from power source.

2. Make sure table insert has been leveled with

table surface (sect. 6.8).

3. Raise blade to highest position and place a

square on table and against blade (Figure 8-4).

Make sure that a blade tooth does not obstruct

the actual reading.

4. Tilt blade with handwheel until square and

blade are flush.

5. If adjustment is required, loosen nut on 90° stop

screw (Figure 8-5) with 13mm wrench, and turn

screw to proper height. Verify setting and

retighten nut against trunnion.

6. Check pointer position on scale (Figure 8-5). If

needed, loosen screw and adjust pointer to

zero. Retighten screw.

Figure 8-4

Figure 8-5: blade stops

Loading...

Loading...