• The output current is enabled / disabled by a digital controlling signal. Please

note that the output current is disconnected until +Vsupply is applied to termi-

nal 3.

Input:

• Programmable current or voltage input for standard signals acc. to order

schedule, joystick / potentiometer or a special non-programmable input.

• Digital inputs for external control functions.

Output:

• A pulsating current output prevents the connected valve from sticking.

• Optional programming of the modulation frequency (PWM) between 8 and 400 Hz.

• The internal measuring and control circuit ensures that the mean current never

exceeds the entered Ivalve.

• If the peak current ex ceeds 7 A the output will be disabled.

23

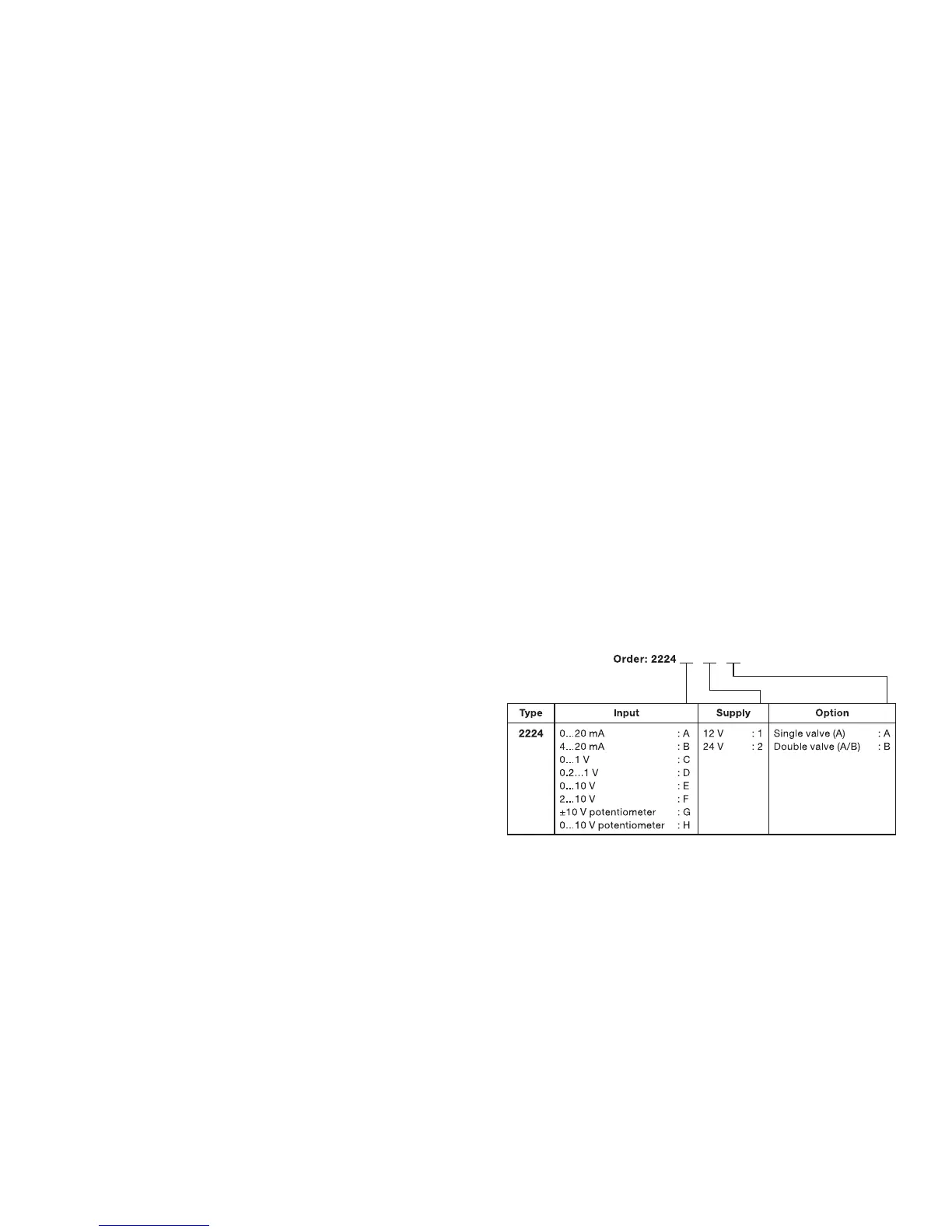

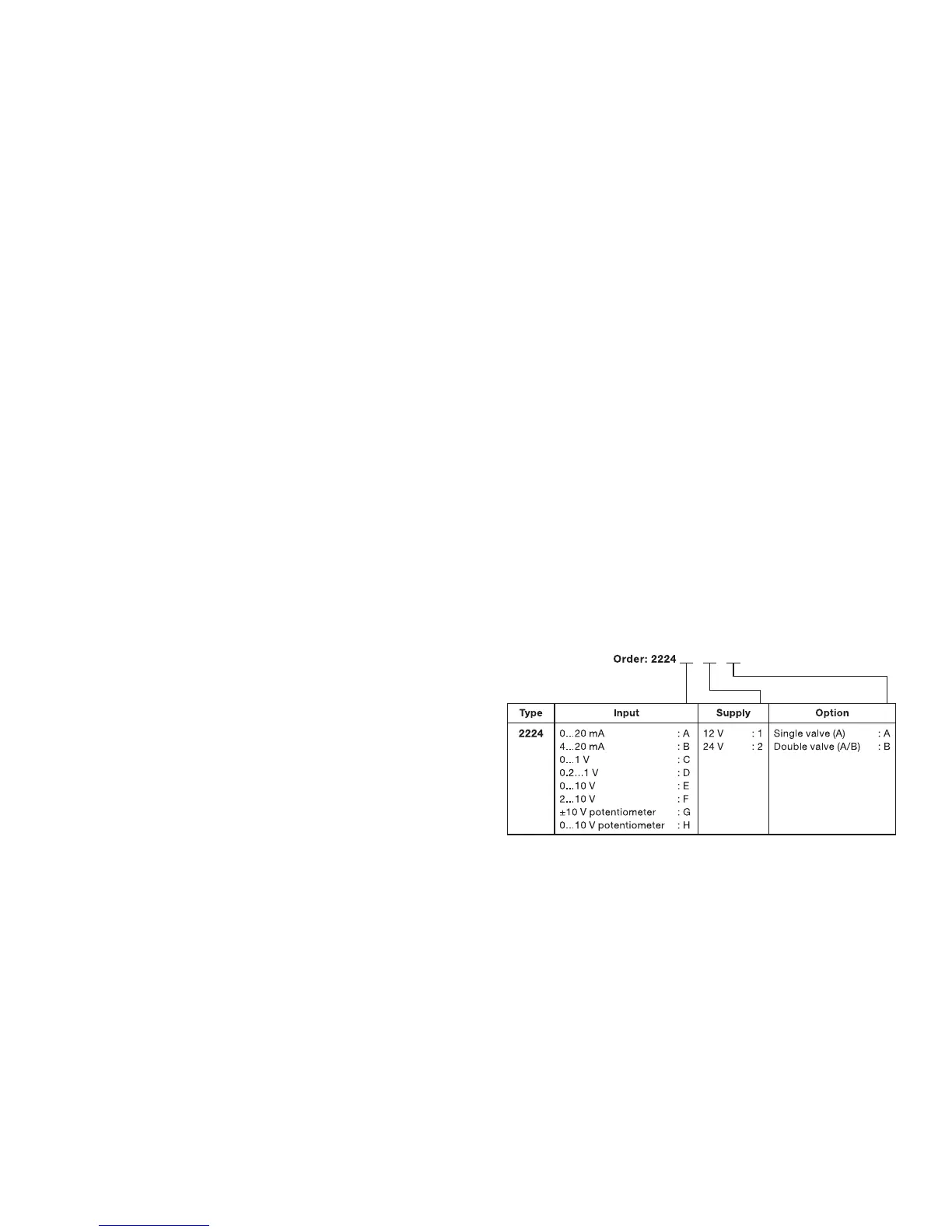

VALVE CONTROLLER 2224

• Front-programmable

• mA, V, and Ω-programmable input

• Ramp times, jump values, reversal, chopper frequency,

and deadband

• 3-digit LED display shows Ivalve % value

• 1 or 2 channels

• Modulated current output for proportional valve

Applications:

• Control and regulation of single or double-coil hydraulic and pneumatic pro-

portional valves.

• The unit is used for accurate oil flow regulation, linear soft acceleration and

deceleration, modulated output signal, and programmable deadband.

• Is highly suitable for joystick regulation of A/B movements.

Technical characteristics:

• The 2224 Valve Controller is a microprocessor-based unit containing ramp

functions for soft start and stop and jump functions thus avoiding deadband

at start and changes between A & B valves.

• The user interface of the valve controller consists of three pushbuttons and a

3-digit LED display. By using these, output currents, ramp times, jump values,

chopper frequency, reversal, deadband, and on/off functions are changed.

• During operation the display shows the present output signal as a % of the

Ivalve.

• All parameters are protected against unauthorised changes with a password.

• Changes between A and B valves can be made in two ways. By way of function

1, the A valve is chosen when +Vsupply is applied to terminal 2. By way of

function 2, changes between A/B valves take place automatically according

to the value of the input signal (no signal on terminal 2).

22

Loading...

Loading...