38

Using the T400 Sensor Installation

Fixture Kit No. 1977-749

(Metric Installation Fixture Kit No. 1974-749)

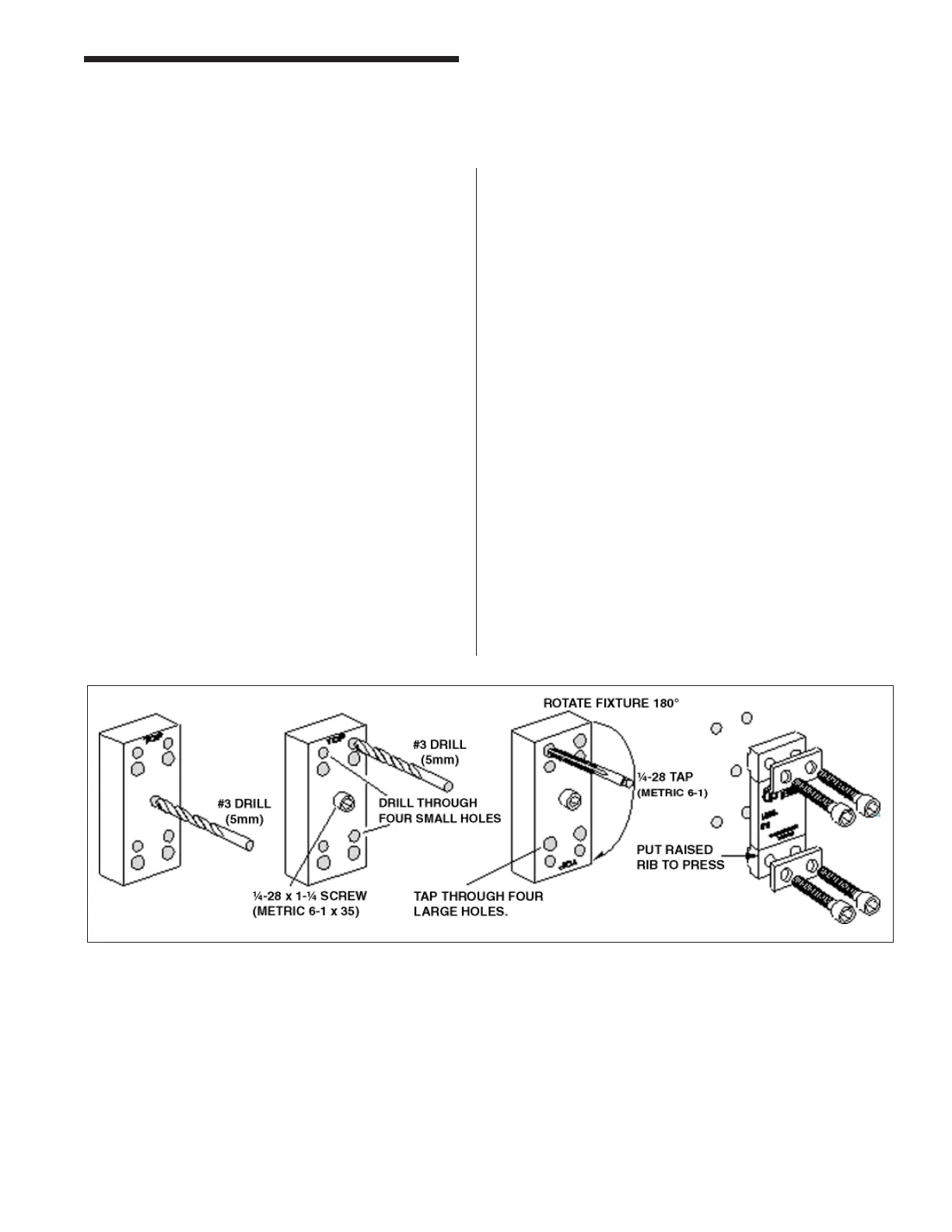

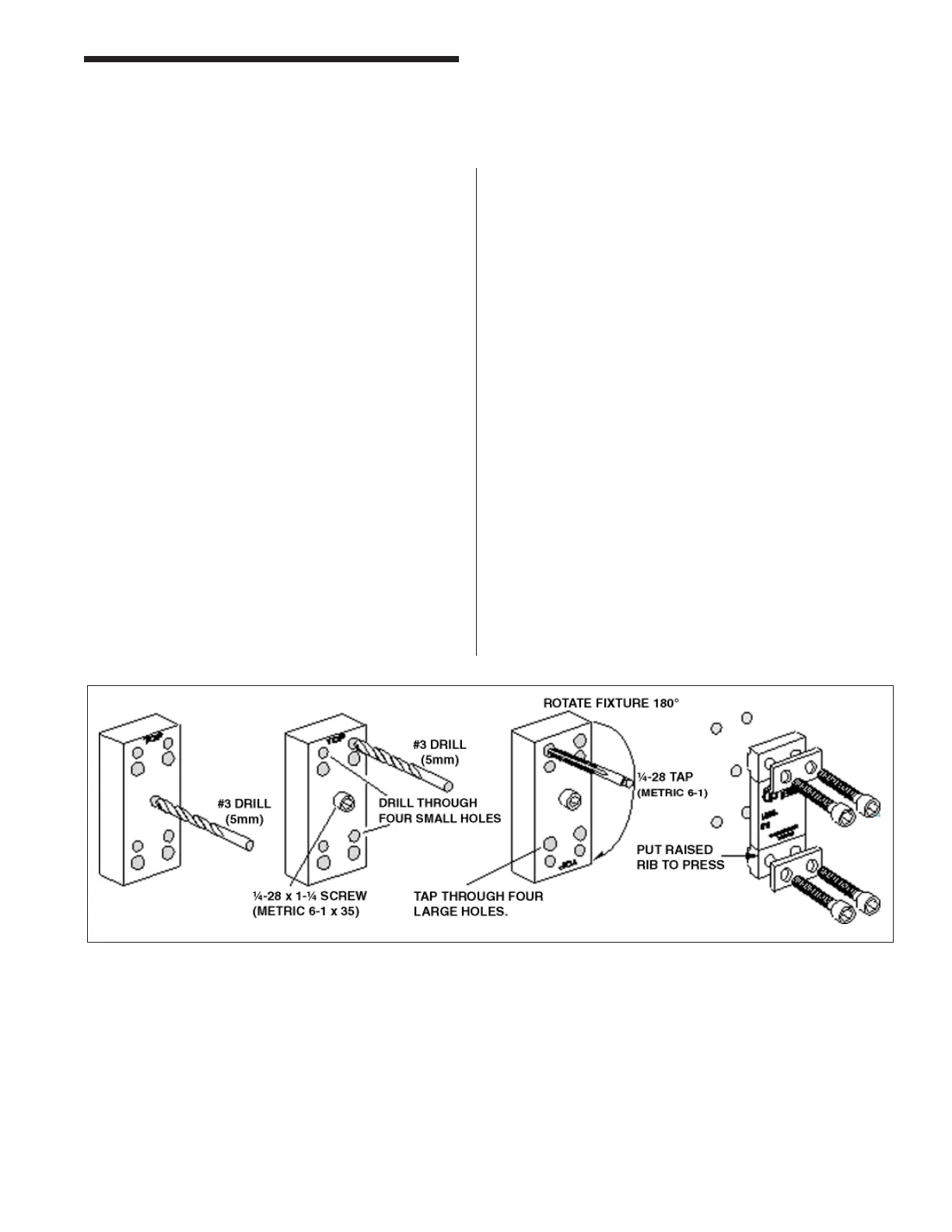

Drill and Tap Method for Mounting Sensors

Step No. 1 Paint must be sanded off and or grease

removed from sensor mount area. If the

machine surface is fl at (total indicated

reading of .002”) and smooth (125 μ in.)

the load sensor can be bolted directly

to the surface.

Step No. 2 Drill and tap the center hole for mounting

the fi xture to the press member. This

hole should be 1/2 of an inch deep. Be

sure the sensor location follows the

best location described on the print.

(Drawing Numbers 3021, 4557).

Step No. 3 Bolt the drill guide to the press member

using the 1/4-28 by 1-1/4 inch (M6-1 X

35) long socket head cap screw in the

center of the guide.

Step No. 4 Insert the number 3 drill (5mm) into the

smaller hole and drill out all four holes

to a depth of 3/4 of an inch.

Step No. 5 Loosen the drill guide. Rotate the drill

guide 180° such that the larger holes

line up with the fresh drilled holes in the

press member. Insert a tap to be sure

the holes line up. Lock the drill guide

by tightening the center socket head

screw.

Step No. 6 Insert the tap into the larger tap guide

holes and tap each hole. Be sure to

use plenty of tapping fl uid.

Step No. 7 Remove the tap guide and continue with

more holes where needed.

Step No. 8 Mount the sensor with raised rib to the

press. The anti-torque washers should

go between the screw and the sensor

body.

Tonnage Load Monitor (optional)

Installation

Loading...

Loading...