100962 G PUBLICATION DATE 24 JUN 2008.DOC PROGRAMMING MANUAL 119

points on the drum pulley. distance.

2. Check the wiring. If the wiring is damaged: repair the wiring.

3. Check the well functioning of the speed sensor.

(The actual speed value is available at the

Service – State menu)

If the speed sensor is broken or not well

functioning, replace the speed sensor.

4. Check the electronic board.

(Inputs can be checked one by one in the

Service menu)

If the input of the electronic board is not

functional, replace the electronic board.

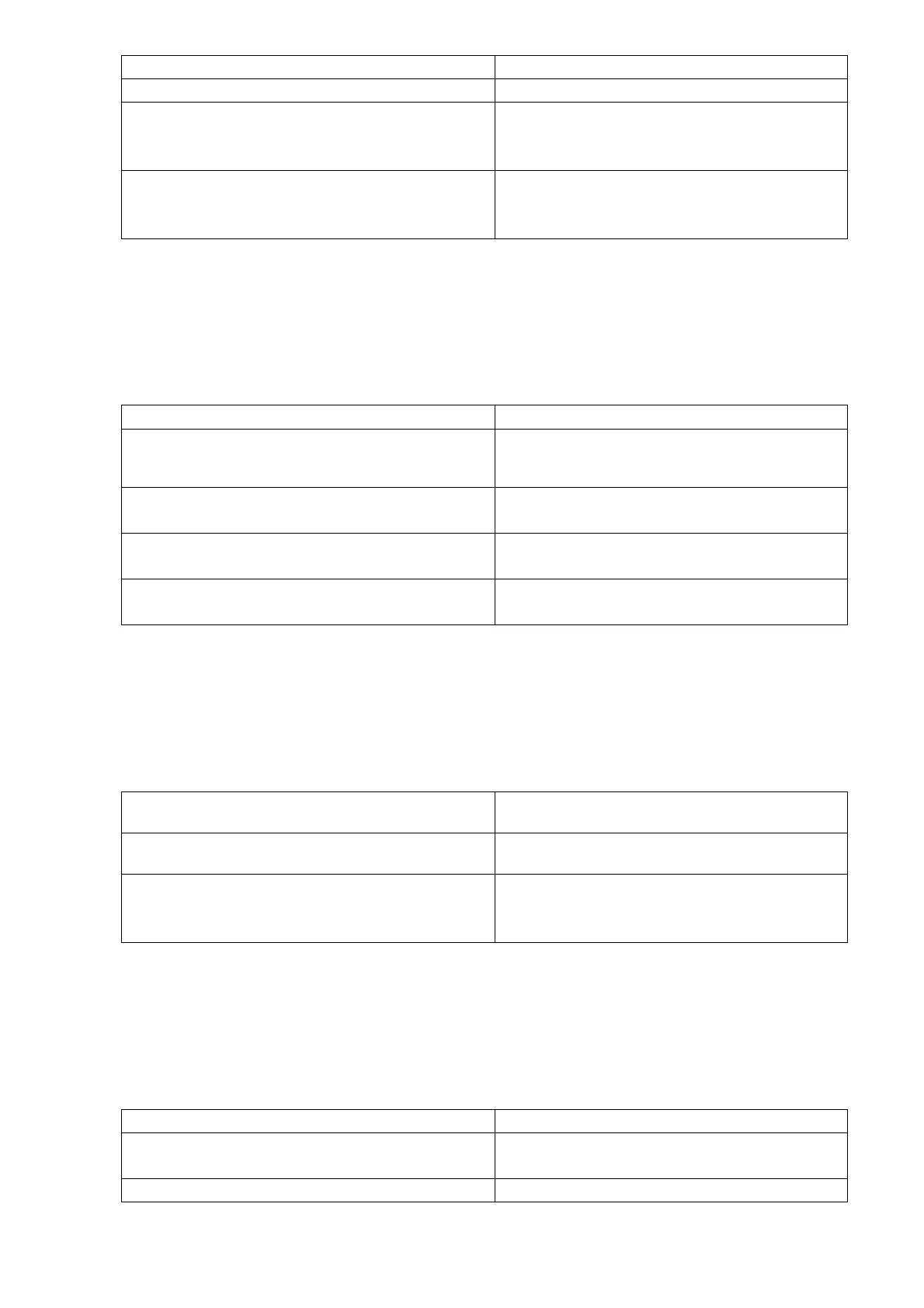

FAILURE 46: BRAKE STAYS CLOSED

F120 machine only. Failure 46 occurs when the mechanical brake stays closed. When the brake stays

closed, at acceleration at spin between 250 and 350 RPM, a too high motor current is detected and the

machine is stopped at once. The machine should not be operated when the brake is out of order. As the

machine operation is deteriorated an intervention of a technician is required.

DIAGNOSE:

1. Check if the main air pressure is available. Apply the correct air pressure.

2. Check if the air pressure that controls the brake

is available.

If the air pressure valves are out of order, repair

or replace the corresponding air pressure

valves.

3. Check the brake control signal wiring that

commands the brake air pressure valve.

If the wiring is damaged: repair the wiring.

4. Check the output relay that powers the control

signal for the brake air pressure valve.

If the relay receives a command signal but is not

closed, replace the electronic board

5. Check the output relay that powers the control

signal for the brake air pressure valve.

If the relay does not receives a command

signal, replace the electronic board

FAILURE 47: BREAK WEAR OUT SIGNAL

F120 machine only. Failure 47 occurs when the friction blocks of the brake are weared out. At the moment

that the friction blocks are almost vanished, two wires will be short circuited when they touch the metal

friction plate. The friction blocks must be replaced at once to avoid heating up of the mechanical brake as this

can damage the machine and lead to an unsafe state.

DIAGNOSE:

1. Check if the friction blocks must be replaced. If the friction blocks have almost vanished, they

must be replaced.

2. Check if the wiring of the input signal Break

Wear Out is not damaged.

If the wiring is damaged: repair the wiring.

3. Check the electronic board.

(Inputs can be checked one by one in the

Service menu)

If the input of the electronic board is not

functional, replace the electronic board.

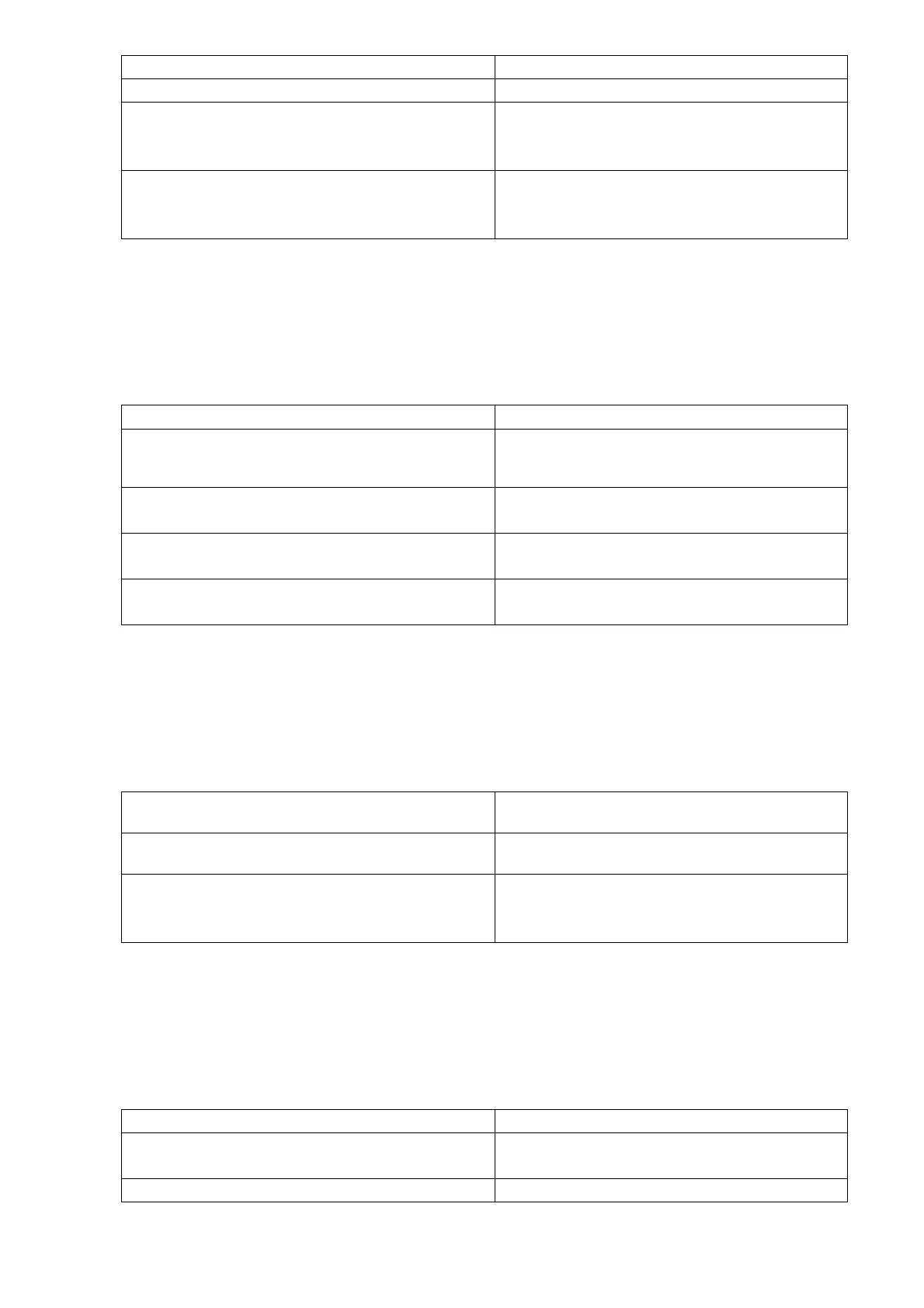

FAILURE 48: BRAKE STAYS OPEN

F120 machine only. Failure 48 occurs when the mechanical brake stays open. When the brake stays open,

the free run time of the machine at deceleration after spin will be much bigger then normal. The machine is

still operational when the brake is out of order. But as the machine operation is deteriorated an intervention of

a technician is required.

DIAGNOSE:

1. Check if the main air pressure is available. Apply the correct air pressure.

2. Check if the air pressure that controls the brake

is available.

If the air pressure valves are out of order, repair

or replace the corresponding air pressure valves.

3. Check the brake control signal wiring that If the wiring is damaged: repair the wiring.

Loading...

Loading...