35

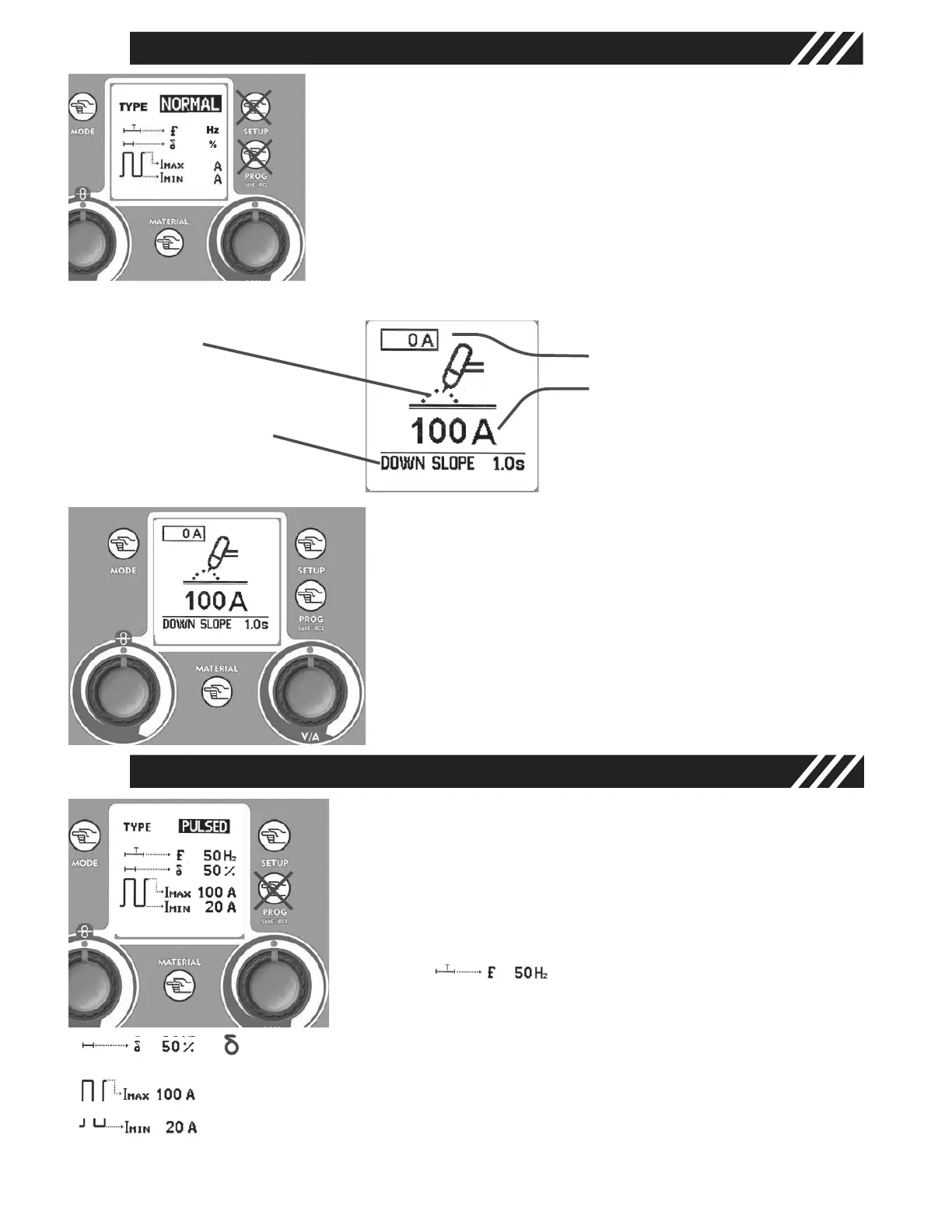

In NORMAL Mode use the Regulation Knobs - 7.2 - and - 5 - to

adjust the following parameters on the main screen:

Left Knob - 7.2 - adjusts the Slope Down Time

Right Knob -

5 - adjusts the welding current

5

7.2

1

MATERIAL KEY - 6.1 -

Press the Material Key and turn the Right regulation Knob - 5 - to

select the working “NORMAL”.

Go back to the main screen by pressing the Mode Key - 1 -.

TIG WELDING IN NORMAL MODE

6.1

5

Graphic Display - 2 -

• TIG Mode

• Slope Down expres-

sed in seconds.

• Real Current

• Set Current

1

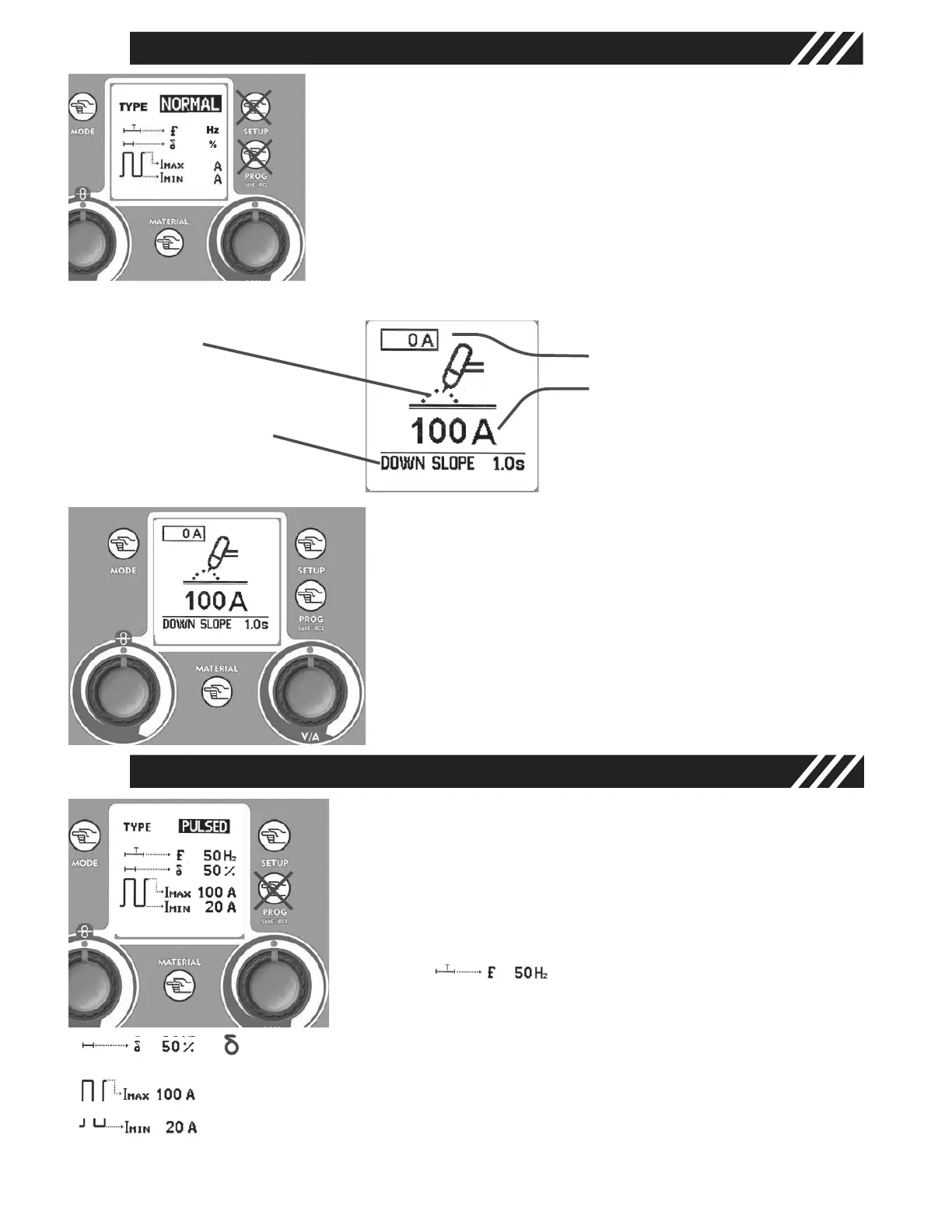

MATERIAL KEY - 6.1 -

Press the Material Key and turn the Right Regulation Knob

- 5 - to select the working “PULSED”.

Press the Setup Key - 3 - to run through the adjustable

parameters and adjust their values by turning the Right

Regulation Knob - 5 -.

Adjustable parameters in Pulsed Mode are:

Pulsation Frequency (

f) Regulation

of the Pulsation Frequency to grant

excellent quality and appearance

results (1-250 Hz)

6.1

5

corresponds to the Ton percentage (20% - 80%); adjusting the duty cycle in

pulsed mode allows the peak current keeping for a longer or shorter time.

I Max (Peak Current) Regulation of the peak current value (5 - 200 amps)

I Min (base current) Regulation of the base current value (5 amps to I Max value)

TIG WELDING IN PULSED MODE

Figure 14

Figure 12

Figure 15

Figure 13

To save and recall later these parameters use the Prog Save & Recall Key - 4 -. Refer to paragraph “TIG

AND MIG/MAG SETUPS SAVE & RECALL”.

13

Loading...

Loading...