Technician Setup Menu

Technician Setup Menu

14

15

16

13

This feature allows the installer

to change the calibration of the

room temperature display. For

example, if the thermostat reads

70˚ and you would like it to read

72˚ then select +2.

OFF

This feature will ash a reminder

after the elapsed run time to

remind the user to change the

lter. A setting of “OFF” will

disable this feature.

Filter Change

Reminder

You can adjust the lter

change reminder from “OFF”

to 2000 hours of runtime in

50 hour increments.

Tech Setup Steps

Room

Temperature

Calibration

0˚F

You can adjust the room

temperature display to read

up to 4˚above or below the

factory calibrated reading.

Adjustment Options Default

LCD Will Show

FILTER

OF

0

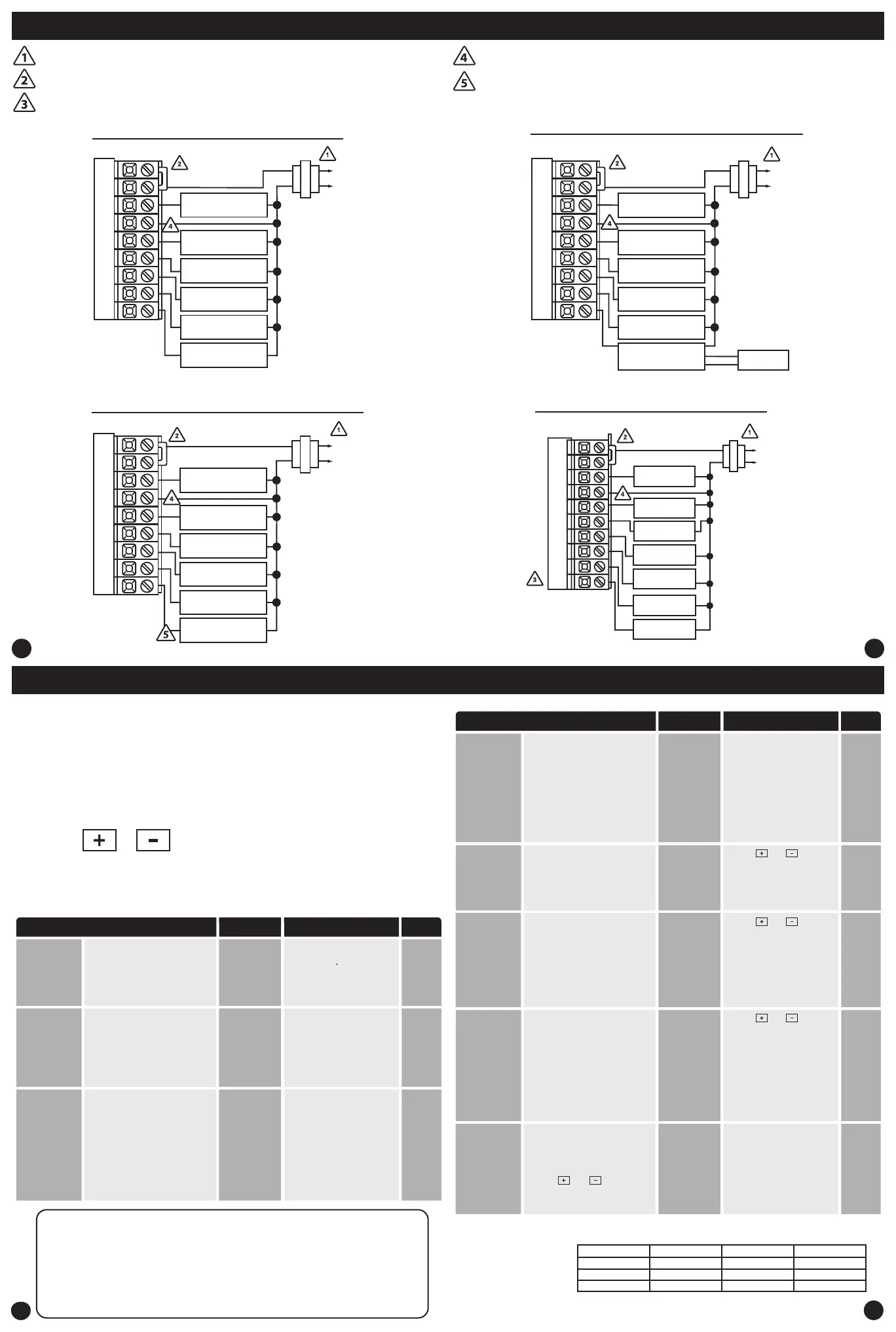

This thermostat has a technician setup menu for easy installer

conguration. To set up the thermostat for your particular application:

1. Press the MENU button.

2. Press and hold the TECH SET button for 3 seconds. This 3

second delay is designed so that homeowners do not accidentally

access the installer settings.

3. Congure the installer options as desired using the table below.

Use the or keys to change settings and the NEXT

or PREV key to move from one step to another.

Note: Only press the DONE key when you want to exit the

Technician Setup options.

4. Press the DONE key to exit.

Tech Setup Steps Adjustment Options Default

LCD Will Show

This setting will select the

terminal for medium fan speed

operations. The selected terminal

cannot be used for reversing valve

operations when heat pump is

enabled.

Use the and buttons to

select O/B terminals.

0

0

The swing setting often called

“cycle rate”, “dierential” or

“anticipation” is adjustable. A

smaller swing setting will cause

more frequent cycles and a larger

swing setting will cause fewer

cycles.

Cooling

Swing

The cooling swing setting

is adjustable from 0.2˚ to

2˚. For example: A swing

setting of 0.5˚ will turn the

cooling on at approximately

0.5˚ above the setpoint

and turn the cooling o at

approximately 0.5˚ below

the setpoint.

The swing setting often called

“cycle rate”, “dierential”, or

“anticipation” is adjustable. A

smaller swing setting will cause

more frequent cycles and a larger

swing setting will cause fewer

cycles.

Heating

Swing

0.5

0.5˚

The heating swing setting is

adjustable from 0.2˚ to 2˚.

For example: A swing setting

of 0.5˚ will turn the heating

on at approximately 0.5˚

below the setpoint and turn

the heating o at 0.5˚ above

the setpoint.

0.4˚

0.4

Swing Setting Tip

The second stage will turn on at 2x the swing setting. The second stage will

turn o when 1x the swing is reached. For example, if the swing setting is .5

degrees for heating and the thermostat is set at 70˚F, the rst stage will turn

on at approximately 69.5˚F. The second stage will turn on at 69˚F. The second

stage will turn o at 69.5˚F and the rst will turn o at 70.5˚F. If the third

stage is used, it will turn on at 68.5˚F and turn o at approximately 69˚F.

COOL SWING

HEAT SWING

MED FAN TERM

CALIBRATE

PTAC Mode

This setting allows the thermostat

to operate a PTAC. This will allow

for multiple fan speeds selectable

in the next two tech settings.

Use the and buttons to

select ON/OFF.

OFF

OF

PTAC MODE

This setting allows you to choose

the number of fan speeds the

thermostat will control.

G = Low Speed Fan

B/O = Medieum Speed Fan

Y2 = High Speed Fan

PTAC Fan

Speeds

(Only displayed

if PTAC mode is

“ON”)

2

2

FAN SPEEDS

When turned on the thermostat

will operate a heat pump. EM.

Heat will show as an option in the

system switch tech setting.

Use the and button to

adjust.

Heat Pump

OFF congures the

thermostat for conventional

systems.

ON congures the

thermostat for heat pump

systems.

OFF

OF

HEAT PUMP

Use the and buttons to

select , 2 or 3.

1. Speeds: ON, Auto

2. Speeds: Low, High, Auto

3. Speeds: Low, Med, High,

Auto

Default Heat Heat Options Cool Default

Cool Options

PTAC (conventional)

PTAC (Heat Pump)

Heat Pump

Conventional

System Mode

1

2

2

2

1

2, 1

5, 4, 3, 2, 1

2, 1

1

1

2

2

1

1

3, 2, 1

3, 2, 1

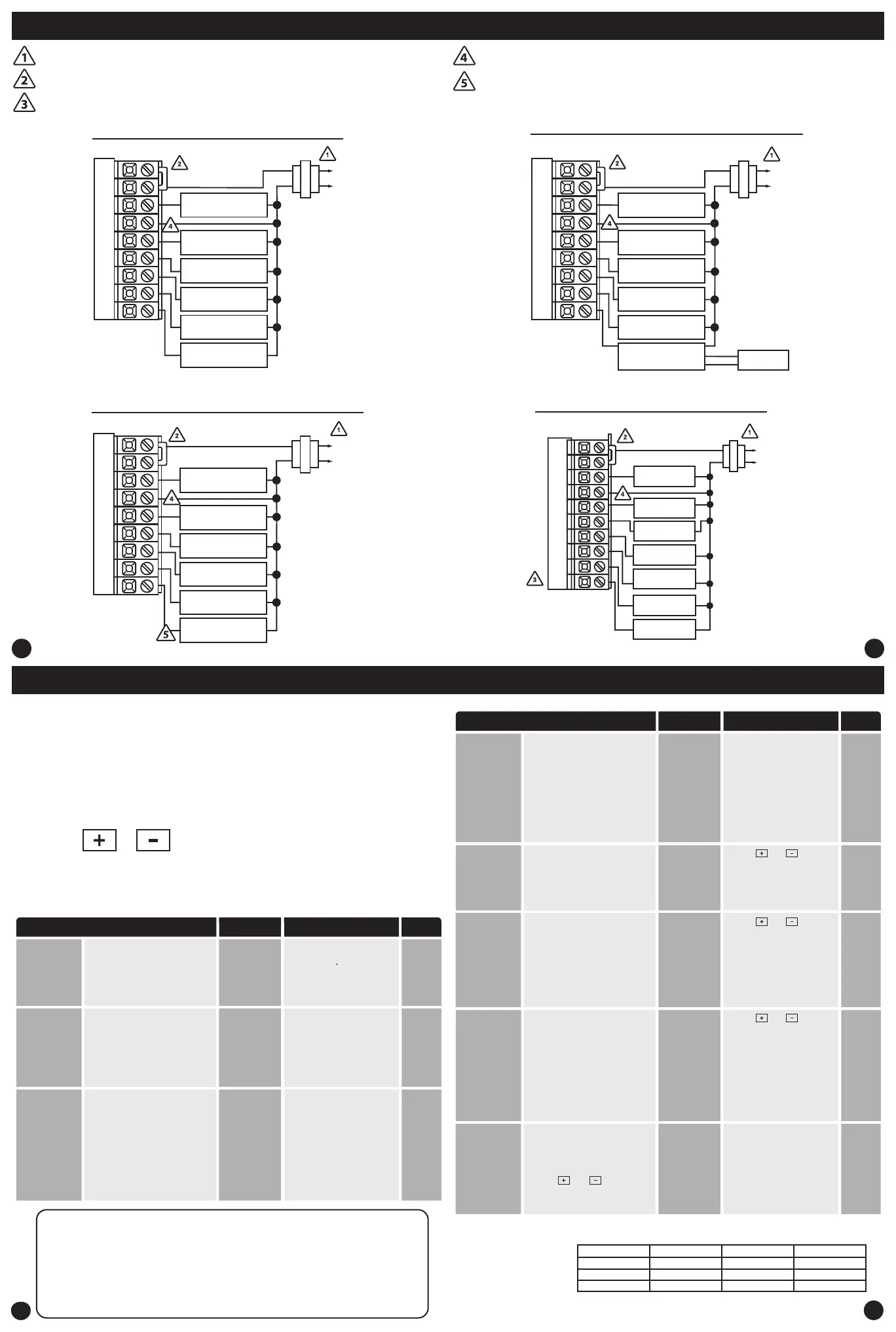

Typical 2H/2C system with 24 VAC Humidier

Typical 2H/2C system with Dehumidify Terminal

L2

L1(HOT)

C

R

RC

RH

Y

C

G

W/E

W2

Y2

H

COMPRESSOR

RELAY

HUMIDIFIER

HEAT RELAY

FAN RELAY

HEAT RELAY 2

COMPRESSOR

RELAY 2

RC

RH

Y

C

W/E

G

W2

Y2

D

COMPRESSOR

RELAY

HEAT RELAY

FAN RELAY

HEAT RELAY 2

COMPRESSOR

RELAY 2

DEHUMIDIFIER

RELAY

L2

L1(HOT)

C

R

Typical 2H/2C system with Dry Contact Humidier

RC

RH

Y

C

W/E

G

W2

Y2

H

COMPRESSOR

RELAY

24V RELAY

NORMALLY-OPEN

TERMINALS

HEAT RELAY

FAN RELAY

HEAT RELAY 2

COMPRESSOR

RELAY 2

L2

L1(HOT)

C

R

DRY CONTACT

HUMIDIFIER

HUM

HUM

Wiring Diagrams Wiring Diagrams

Power supply

Factory - installed jumper. Remove only when installing on 2 transformer systems.

Use either O or B terminals for changeover valve.

A 24 VAC common connection is required with this thermostat.

If DEHUM relay requires a normally-energized input, set Dehumidify relay to NC

in Technician Setup.

Typical 5H/3C Heat Pump System

RC

RH

Y

C

W/E

G

W2

Y2

COMPRESSOR

RELAY 1

FAN RELAY

AUXILIARY

HEAT 2

COMPRESSOR

RELAY 2

AUXILIARY

HEAT 1

C

R

L2

L1(HOT)

O

B

COOL

CHANGEOVER OR

COMPRESSOR 3

HEAT

CHANGEOVER OR

COMPRESSOR 3

PTAC Medium

Fan Speed

Terminal

(Only displayed

if PTAC mode is

ON and PTAC fan

speeds is set to 3)

Loading...

Loading...