13

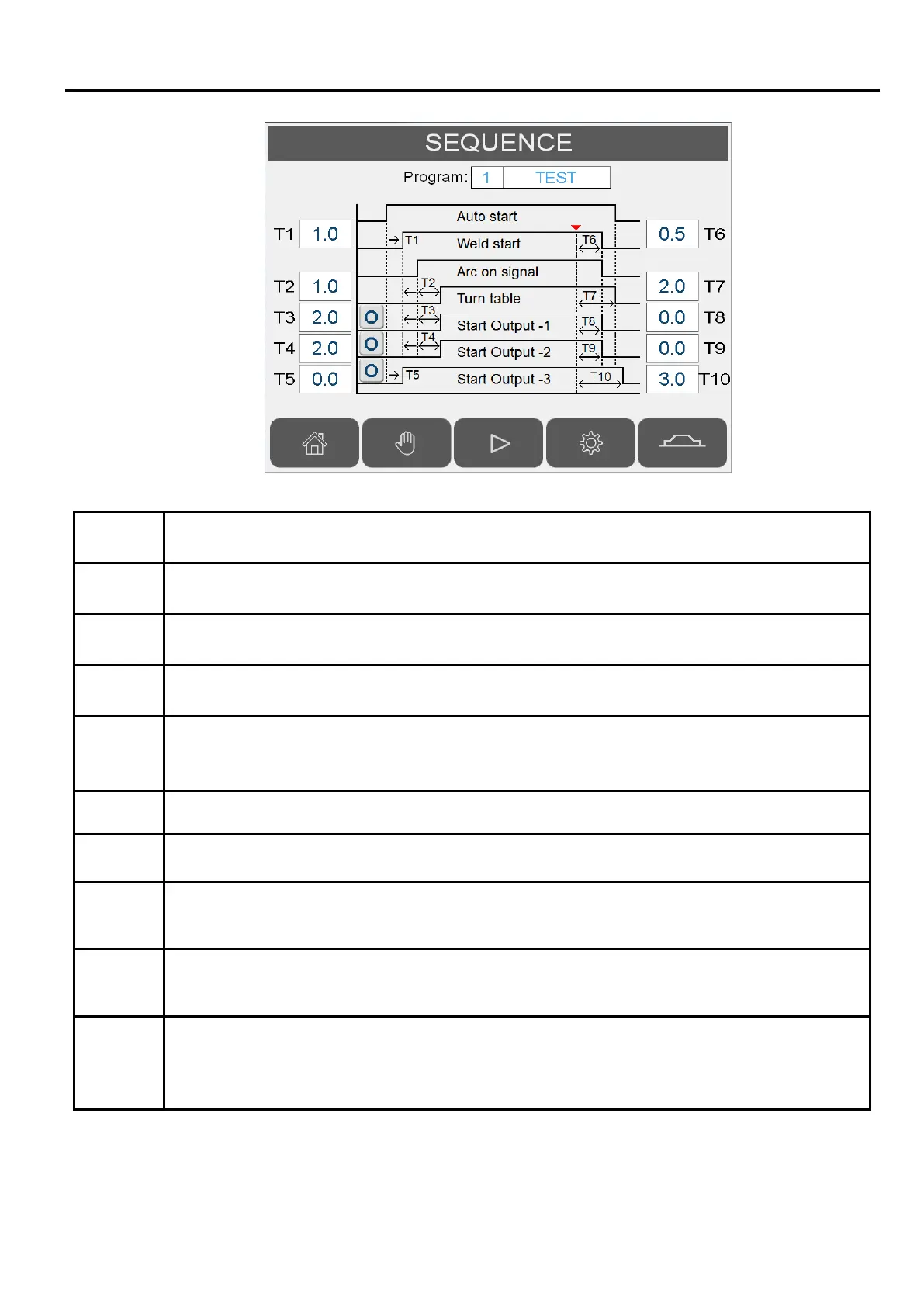

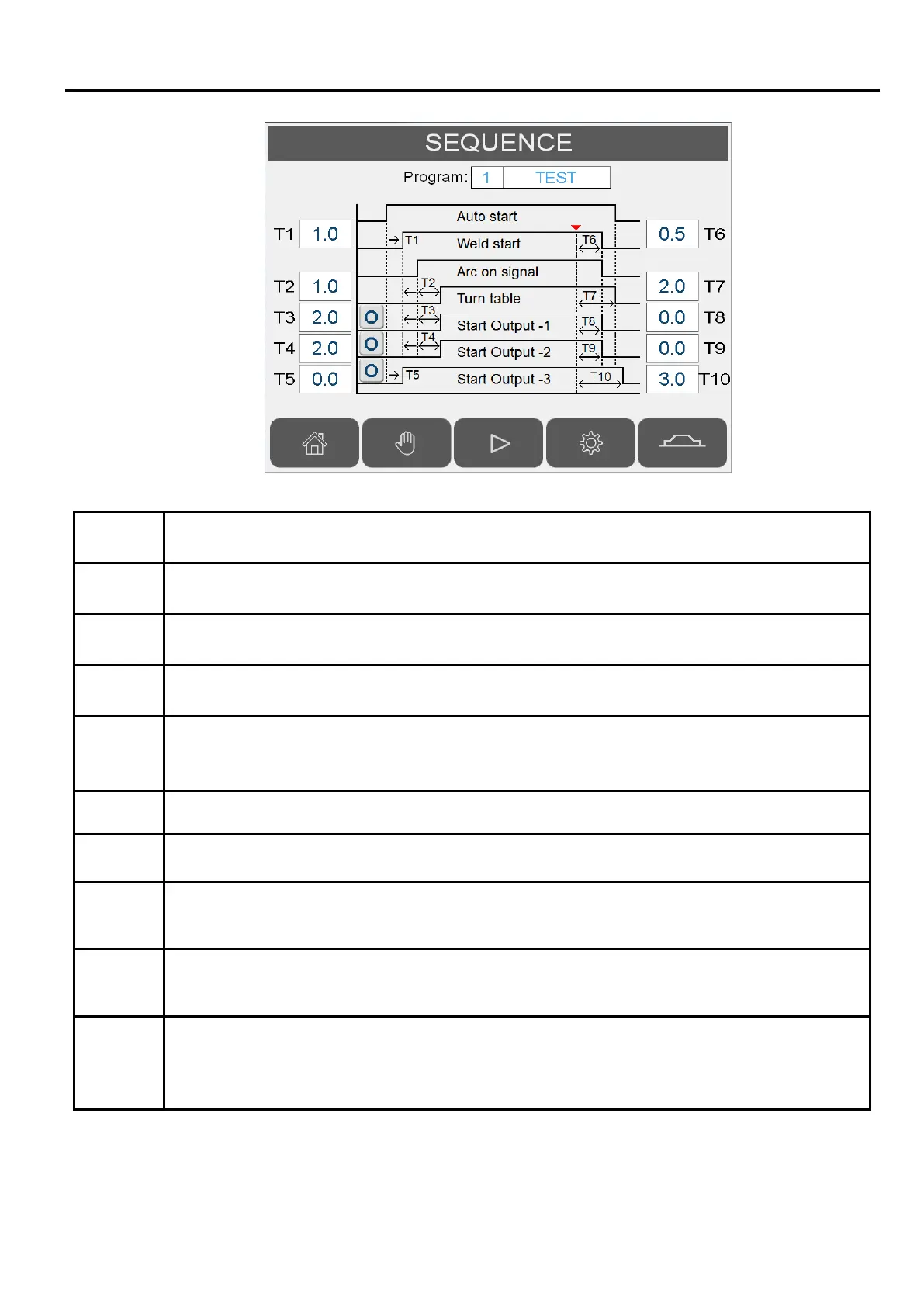

2.8 WELDING SEQUENCE SETTING

T1 Welder ON delay after auto start is activated.

T2 Turn table rotation delay after arc on signal is received.

T3 Dry contact output-1 ON delay after arc on signal is received.

T4 Dry contact output-2 ON delay after arc on signal is received.

T5

Dry contact output-3 ON delay after auto start is activated.

Used for protective gas activation or pneumatic torch lifter.

T6 Welder OFF delay after turn table has reached target program position.

T7 Turn table stop delay after turn table has reached target program position.

T8

Dry contact output-1 OFF delay after turn table has reached target program position.

Also switches off when both T6 and T7 timer are finished.

T9

Dry contact output-2 OFF delay after turn table has reached target program position.

Also switches off when both T6 and T7 timer are finished.

T10

Dry contact output-3 OFF delay after turn table has reached target program position.

Output-3 is not limited by T6 and T7 timer, can be set for longer delay action like welding

protective gas or pneumatic torch lifter.

Loading...

Loading...